Stereo compact spinning device of spinning frame

A spinning frame and three-dimensional technology, applied in the field of three-dimensional compact spinning devices, can solve the problems of yarn breakage, complex structure and high production cost, and achieve the effects of avoiding yarn jamming and yarn breakage, improving yarn quality and improving conveying form.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

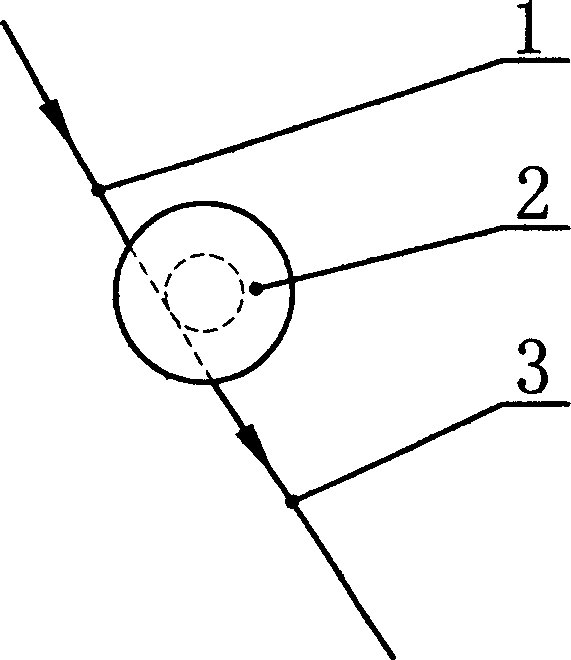

[0013] Such as figure 1 , figure 2 As shown, the present invention is provided with a cylindrical yarn guide column 2, which is installed below the bottom roller of the spinning frame, and has several circles of spiral grooves 4 on the yarn guide column 2. In this embodiment, the spiral groove 4 Of course, the quantity of the helical groove 4 can also be set according to needs, the cross section of the helical groove 4 is trumpet-shaped, the top of the groove is wide, the bottom of the groove is narrow, and the cross section of the groove bottom is semicircular shape, the width of the groove bottom can be determined according to the count of the processed yarn 3, for the convenience of production and to reduce production costs, the spiral groove 4 on the yarn guide column 2 can be set to different widths, so that it can be used according to the yarn The number of lines 3 is used to select the corresponding groove 4. During work, earlier the twisted yarn 3 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com