2-dimensional code formation method and formation device

A two-dimensional barcode and barcode technology, applied in the field of two-dimensional barcode formation and forming devices, can solve problems such as difficulty in forming two-dimensional barcodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

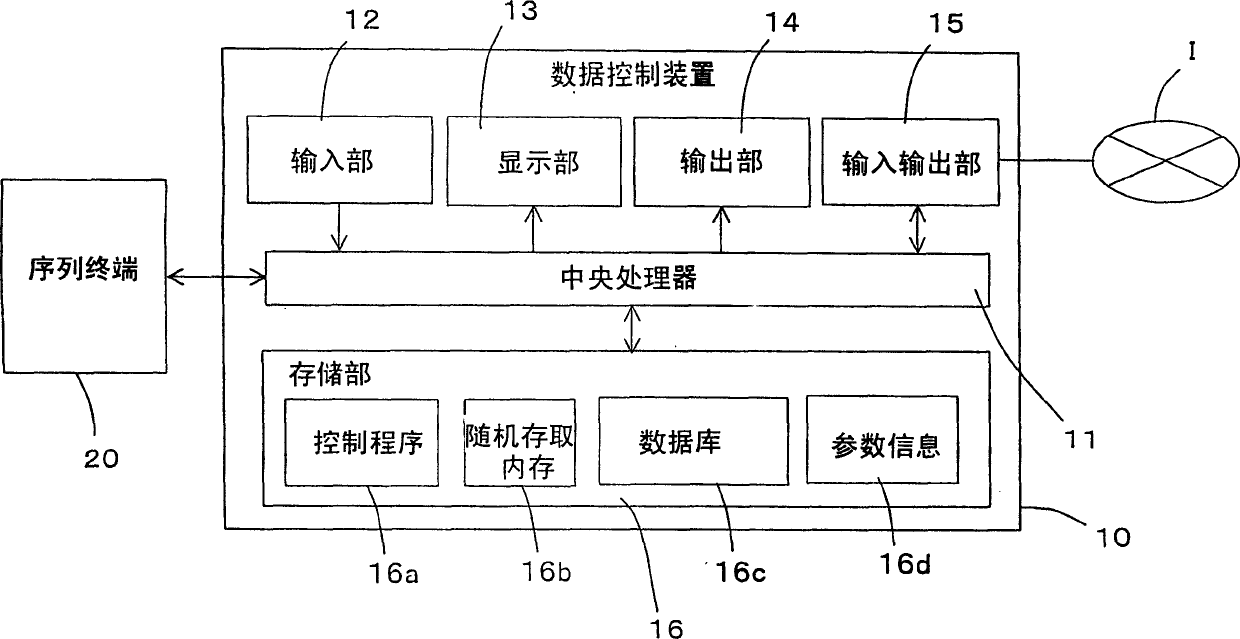

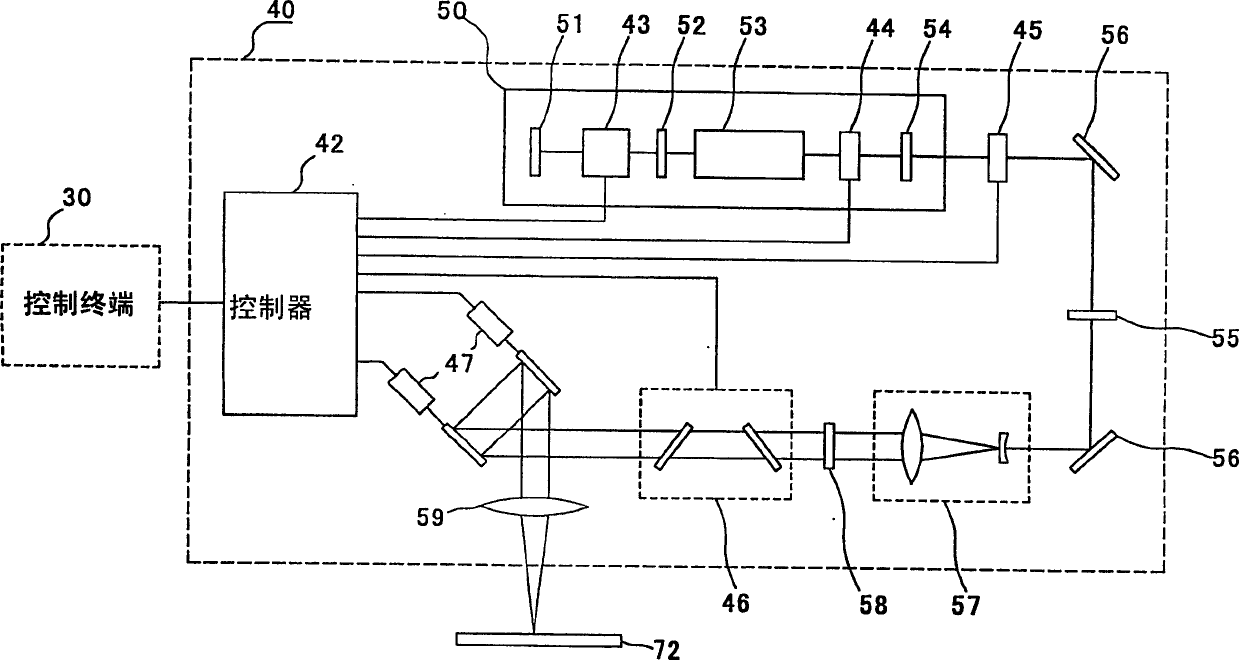

[0062] Hereinafter, embodiments of the present invention will be described with reference to the drawings. At the same time, the components, arrangement, etc. described below are not limited to those mentioned in the present invention, and various changes can be made within the scope of the gist of the present invention.

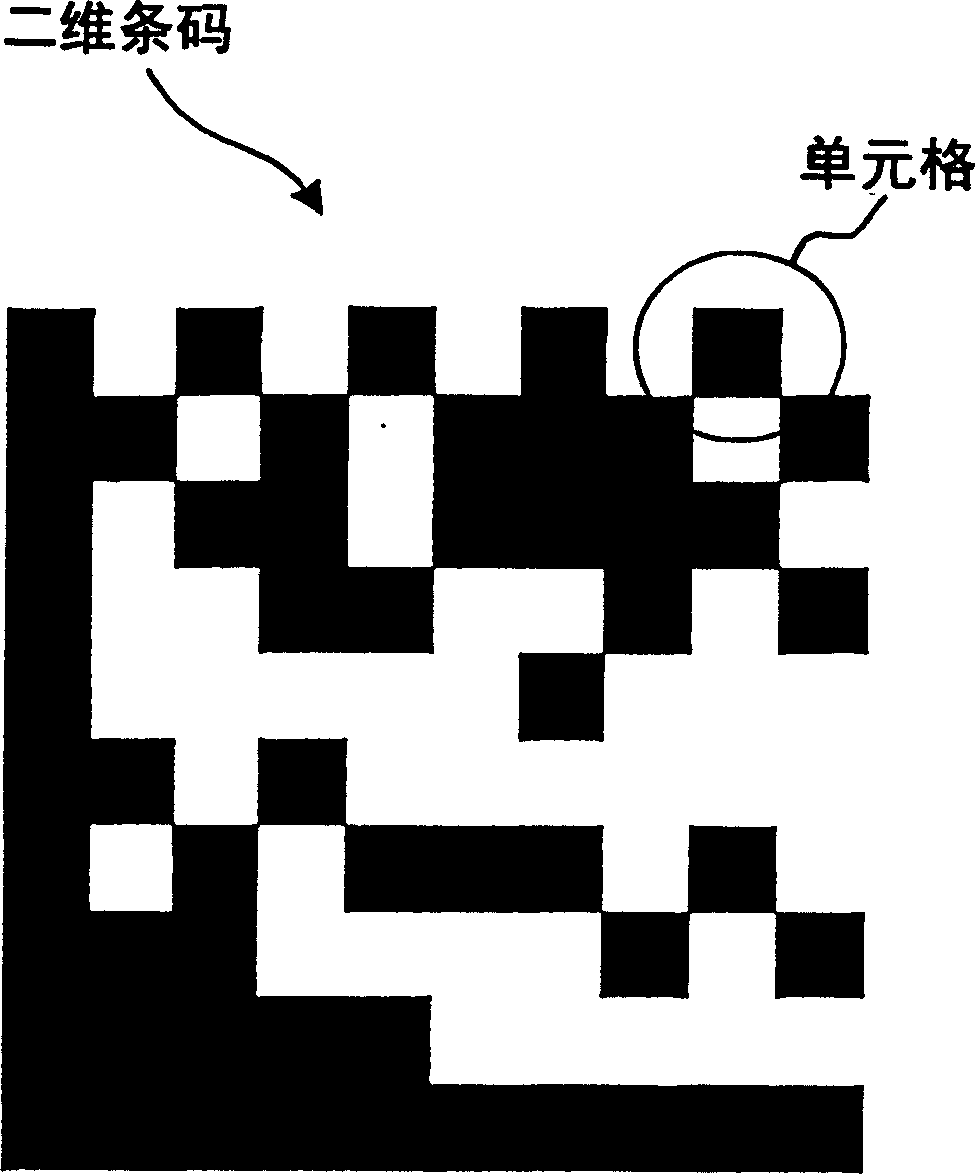

[0063] The two-dimensional barcode related to this embodiment is formed by arranging light and dark cells in a matrix according to dot marks. The form of the two-dimensional barcode can adopt data matrix, QR code (quick response matrix code) and the like.

[0064] The dot marking method refers to a method of creating a two-dimensional barcode by forming a plurality of dots on a marking object. In this specification, it includes two types: a laser marking method and a printing method.

[0065] As shown in FIGS. 3 and 4 , examples of two-dimensional barcodes are shown. A two-dimensional barcode is a combination of white spaces and black bars arranged in a ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com