Anode clamp of pre-calcining anode electrolytic cell

A pre-baked anode and electrolytic cell technology, which is applied in the field of anode clamps for pre-baked anode electrolytic cells, can solve the problems of inconvenient use of pre-baked anode electrolytic cell anode clamps, inability to exert the mechanized advantages of small box clamps, and increased labor intensity of workers. , to achieve the effect of improving labor productivity, light weight and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

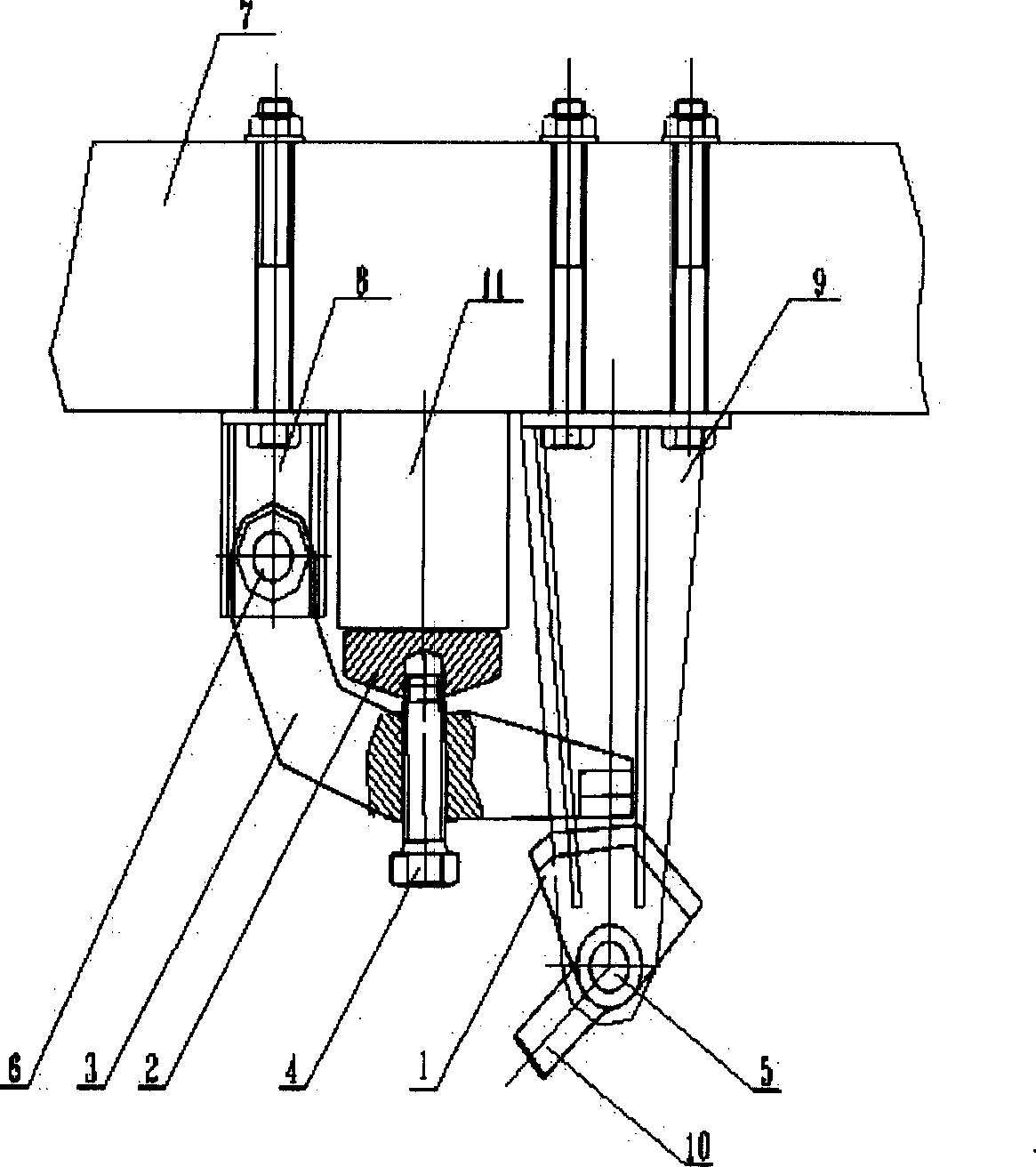

[0007] Embodiment of the present invention: on the existing aluminum electrolytic cell anode busbar (7), the upper left bracket (8) and the right bracket (9) are fixed by bolts, and the connecting rod shaft (6) is passed on the left bracket (8) Connect the upper connecting rod (3), the connecting rod (3) can be made into a straight rod shape or an L-shaped shape, and the adjusting bolt (4) and the adjusting bolt (4) can be installed on the connecting rod (3). press plate (2), then connect the manual eccentric wheel (1) through the eccentric wheel shaft (5) on the right bracket (9), and make the eccentric wheel surface of the manual eccentric wheel (1) and the connecting rod (3) The front end is contacted, and then an operating handle (10) is installed on the manual eccentric wheel (1).

[0008] The invention can be used in prebaked anode electrolyzers with different capacities, and is especially suitable for small prebaked anode electrolyzers as equipment for manually pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com