Plastic ball valve

A technology for plastic ball valves and valve stems, which is applied to valve devices, cocks including cut-off devices, mechanical equipment, etc. It can solve problems such as high friction between seals and valve balls, large wear of seals and valve balls, and large switching torque , to achieve the effect of increasing the amount of elastic deformation, small switching torque and small wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

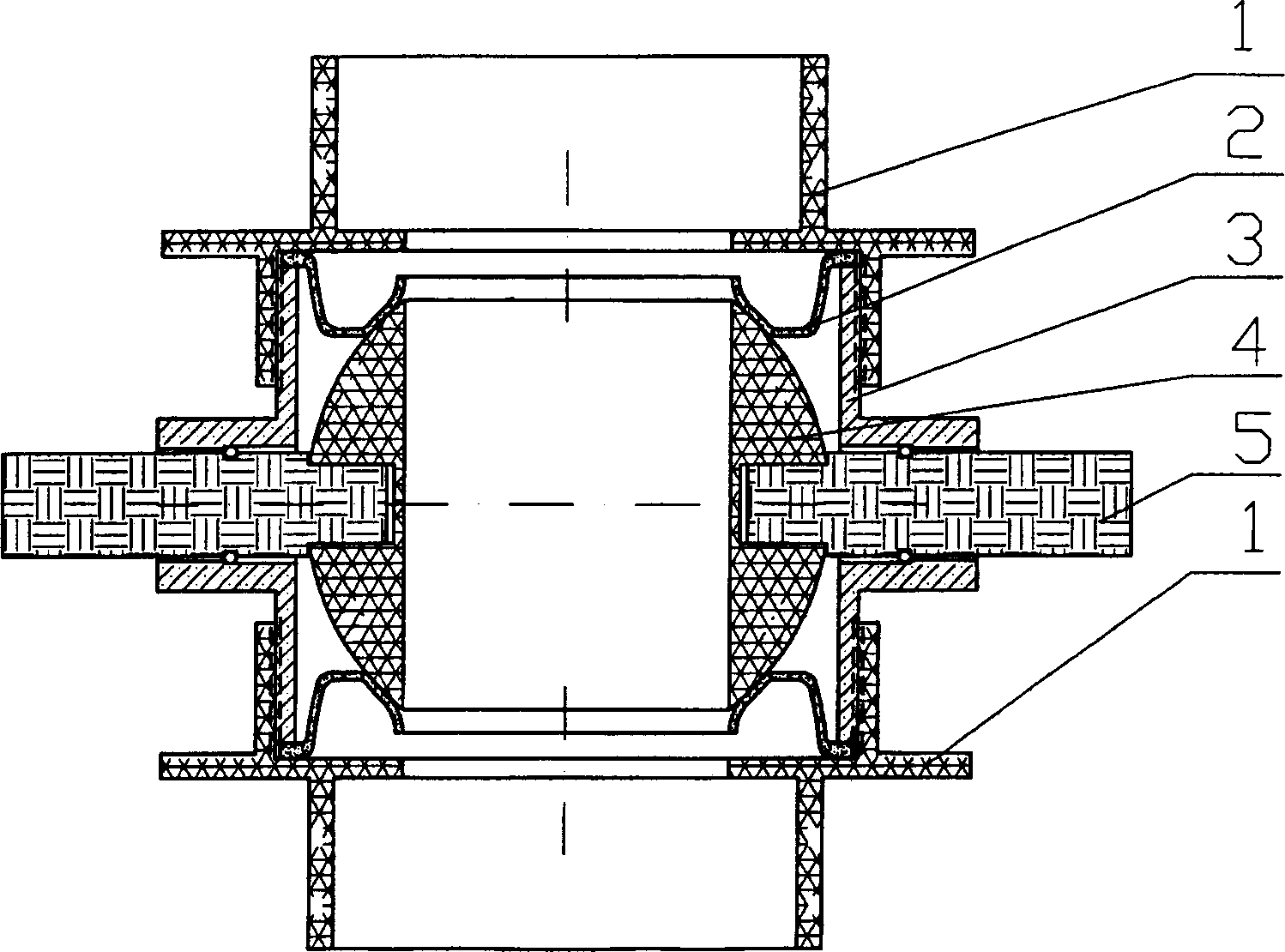

[0008] refer to figure 1 , the plastic ball valve is composed of end cover (1), seal (2), valve body (3), valve ball (4) and valve stem (5), etc., end cover (1), valve body (3), valve ball (4) and valve stem (5) are all used ABS engineering plastics injection molding, and seal (2) is made with polyurethane elastomer, and valve stem (5) place is installed rubber sealing ring, plays the effect of sealing and positioning to valve stem. The valve stem and the valve ball are connected by a wedge groove, the end cover and the valve body are connected by threads, the seal is fixed between the end cover and the valve body, and the inner ring of the seal is in close contact with the valve ball. The ball valve can be opened by manual, pedal and electric methods, and a corresponding switch device is required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com