Uniform radiation microwave heating method and device

A microwave heating device and microwave heating technology, applied in microwave heating, electric heating fuel, lighting and heating equipment, etc., can solve the problems of uneven microwave radiation, large defects, unevenness, etc., to improve reliability and service life, Easy maintenance and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

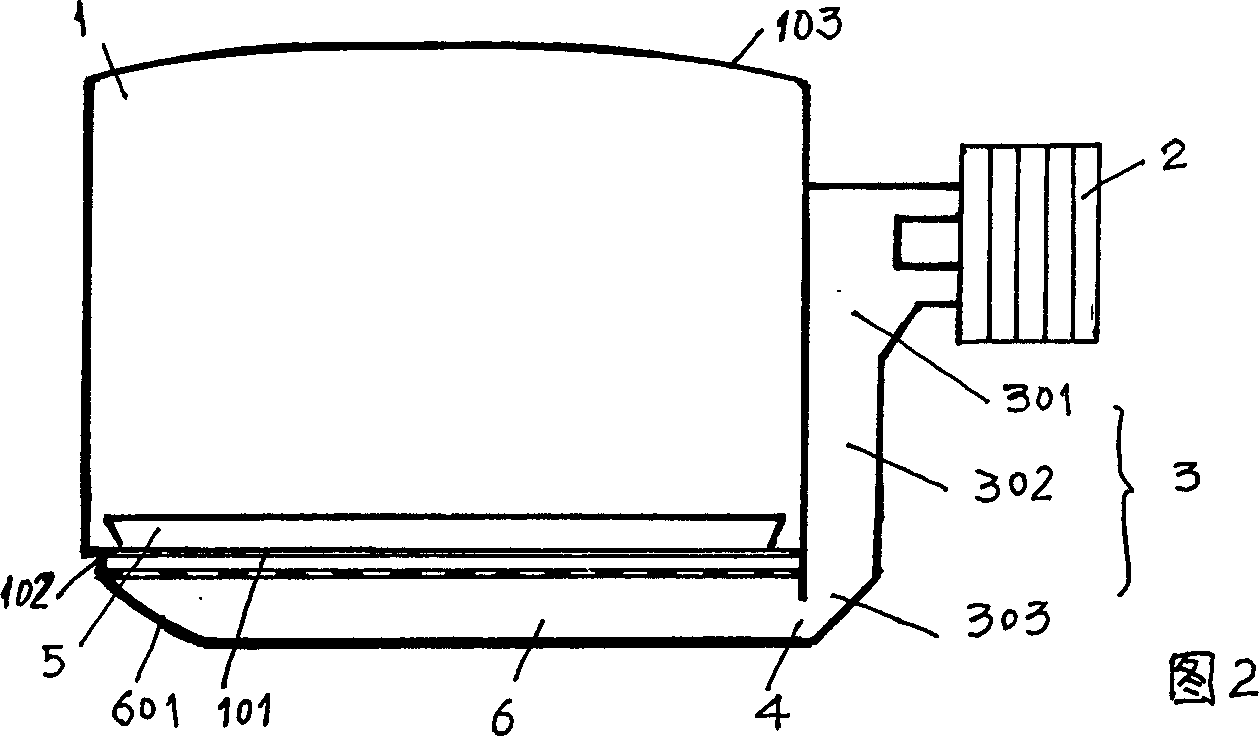

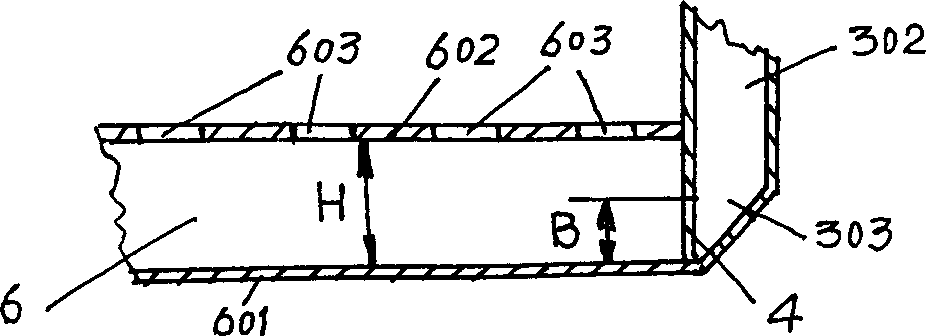

[0045] An embodiment of the uniform radiation microwave heating device of the present invention is a microwave oven, its structure please refer to FIG. 2 . The microwave oven includes a heating cavity 1 , a magnetron 2 , a waveguide impedance converter 3 , a waveguide port 4 , a storage tray 5 and a coupling cavity 6 .

[0046] A magnetron 2 and an impedance transformer 3 are installed on the outside of the right vertical wall of the heating chamber 1 . The bottom surface of the heating chamber 1 is a sealing disc 101 made of ceramics or heat-resistant glass, and the gap around the sealing disc 101 is filled with silica gel 102 . Place the holding tray 5 above the sealing tray 101. The coupling cavity 6 is installed below the sealing disc 101 . The top wall of the heating chamber 1 is provided with a cylindrical converging reflective surface 103 . Of course, the top wall of the heating chamber 1 can also be made as a plane reflective surface.

[0047] The magnetron 2 is co...

Embodiment 2

[0053] The second embodiment of the microwave heating device with uniform radiation of the present invention is specially designed for the multi-functional model that combines drying, disinfection cabinet and microwave oven into one. Its structure see Figure 7 . This uniform radiation microwave heating device has a heating cavity 1, a magnetron 2, a waveguide impedance converter 3, two waveguide ports 410, 420, a storage tray 5 and two coupling cavities 610, 620; The top and bottom surfaces of the cavity 1 respectively have a combined form of an upper coupling cavity 610 and a lower coupling cavity 620 . The microwave energy generated by the magnetron 2 is respectively fed into two different coupling cavities 610 and 620 through the two waveguide ports 410 and 420 connected to the waveguide impedance converter 3; Multiple beams of uniform microwaves form multiple beams of uniform microwave radiation in two directions up and down in the heating chamber 1 .

[0054] A magnet...

Embodiment 3

[0061] The third embodiment of the uniform radiation microwave heating device of the present invention is an improved design for the previous embodiment, and its structure please refer to Figure 8 . This uniform radiation microwave heating device has a heating chamber 1, a magnetron 2, a waveguide impedance converter 3, two waveguide ports 410, 420, a storage tray 5 and three coupling cavities 610, 620, 630; The top surface, the bottom surface and the left side of the heating chamber 1 are composed of an upper coupling cavity 610 , a lower coupling cavity 620 and a left coupling cavity 630 respectively. Please compare Figure 7 with Figure 8 The difference between this embodiment and the previous embodiment is: the left side of the upper coupling cavity 610 is provided with a third curved waveguide 333, and the third curved waveguide 333 is connected to the left coupling cavity 630; the left coupling cavity 630 is located on the left side of the heating cavity 1 side. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com