Automatic coagulating agent adding method in soybean curd production process and used automatic coagulating agent adding device

A production process and pulping technology, which is applied in application, food preparation, food science, etc., can solve problems such as low degree of automation and difficult quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0008] Specific implementation mode one: the current bean curd production technological process is as follows:

[0009] Raw soybeans→cleaning→soaking→rinsing→refining (separation of pulp and slag)→raw pulp→cooking pulp→artificial pointing→squatting→braining→press molding→package cooling (→cutting→packaging)→finished product

[0010] The tofu production process described in the present embodiment is as follows:

[0011] Raw soybeans→cleaning→soaking→rinsing→refining (separation of pulp and residue)→raw pulp→cooking pulp→automatic pulping→squatting brain→top brain→press molding→package cooling (→cutting→packaging)→finished product

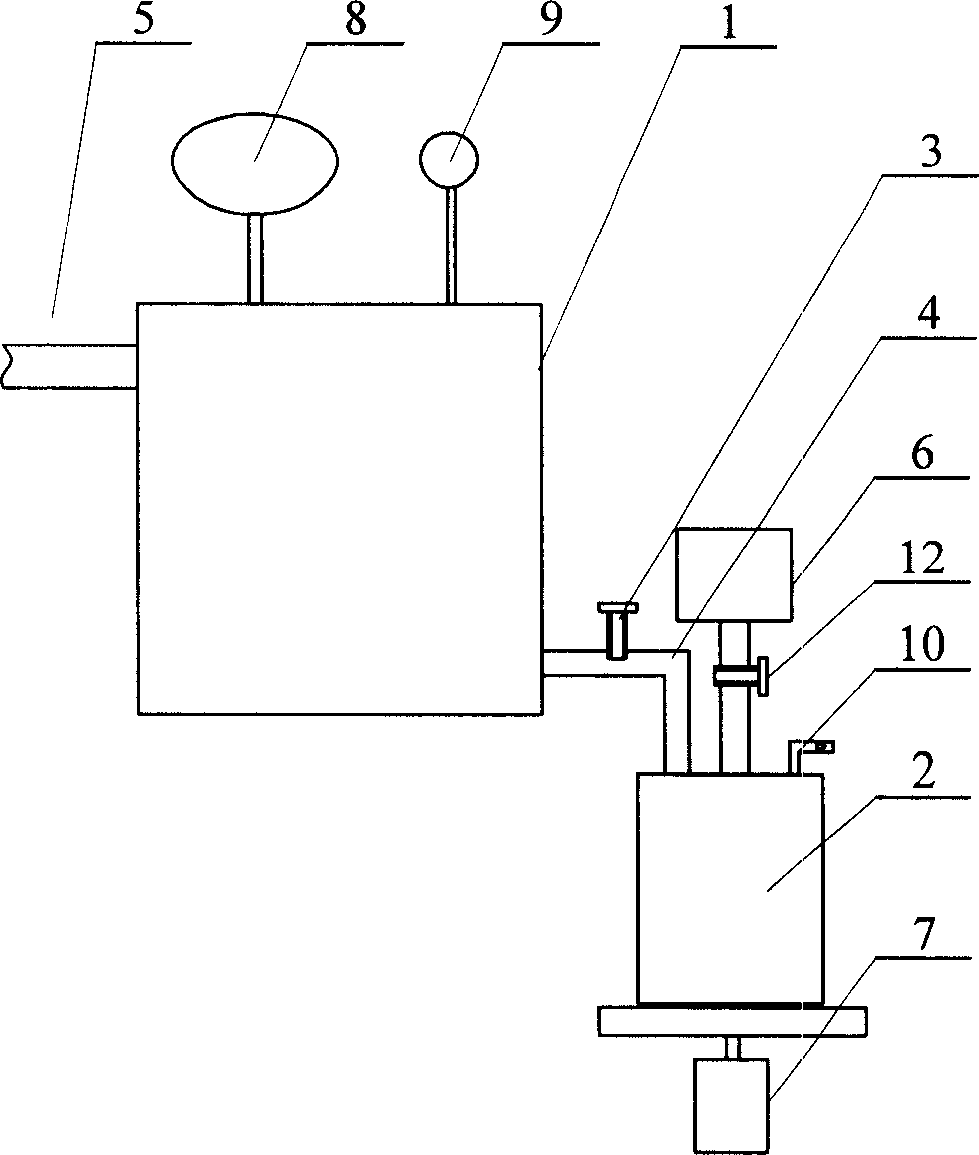

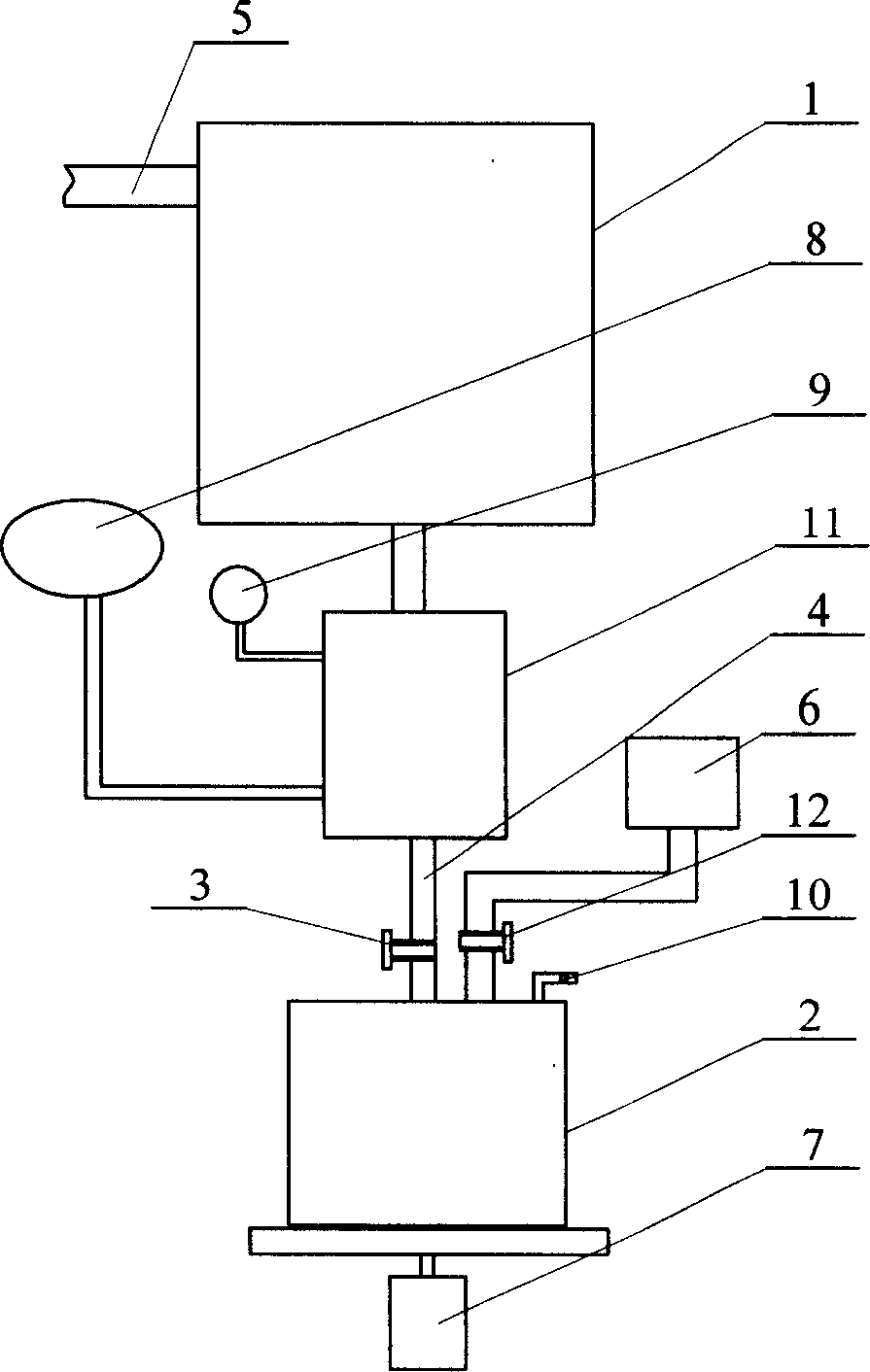

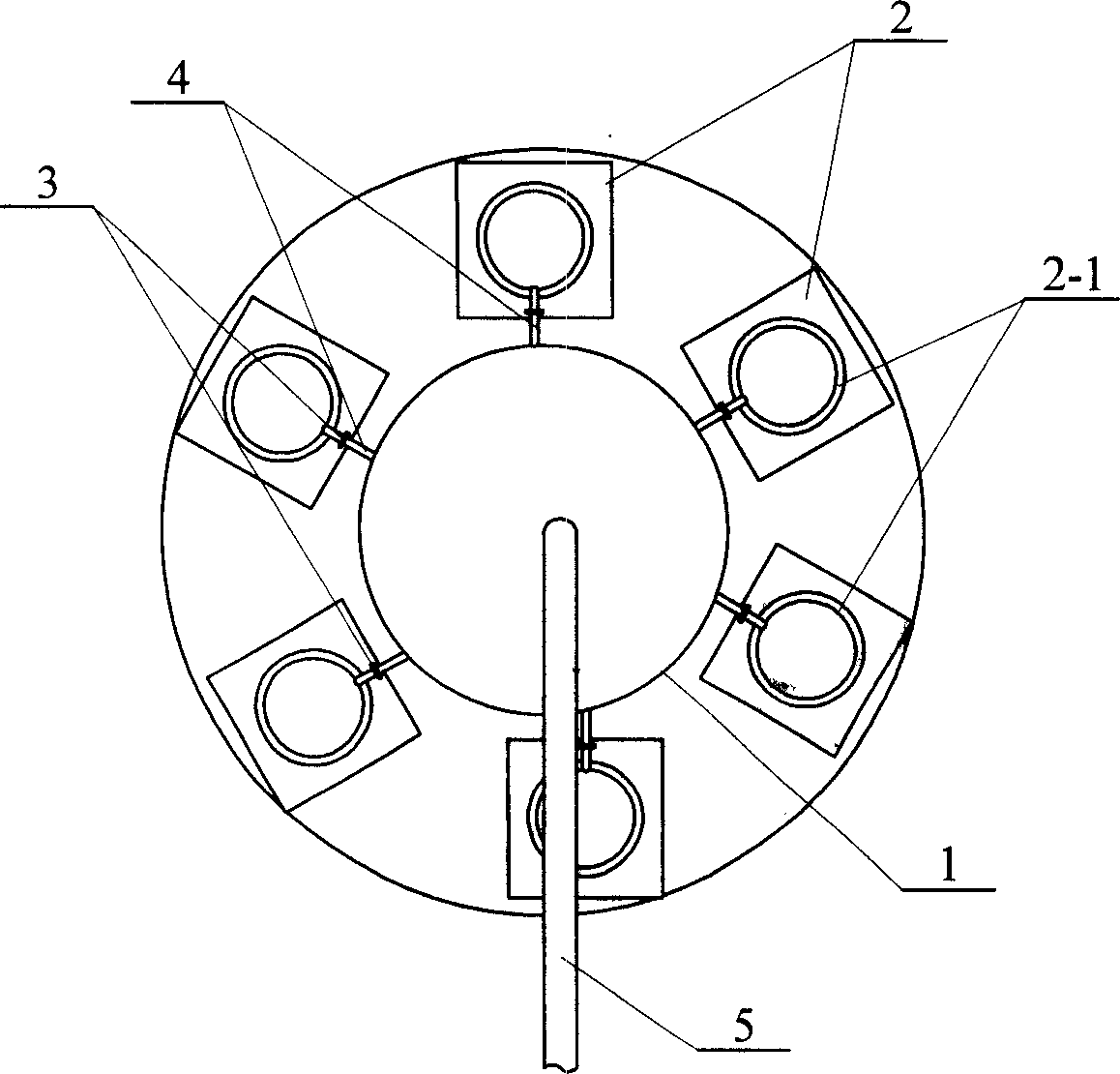

[0012] In the present embodiment, at first the automatic dispensing device used in the tofu production process is set, refer to figure 1 , the device includes a storage tank 1 and a slurry tank 2, the storage tank 1 is provided with a soybean milk input pipeline 5, the storage tank 1 and the slurry tank 2 are connected by a pipeline 4, and a control...

specific Embodiment approach 2

[0014] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the coagulant is CaSO with a concentration of 0.15-0.25 mol / L 4 It is prepared by mixing with brine with a concentration of 1.5-2.0 mol / L in a volume ratio of 6-13:1; the volume ratio between the coagulant and added soybean milk is 1:10-20.

[0015] The overall process of producing bean curd with the coagulant described in this embodiment is as follows:

[0016] (1) Soaking: remove residual beans and impurities from the soybeans, weigh a certain amount, wash three times with tap water, then soak the soybeans with three times the amount of tap water, soak for 9 hours at room temperature (about 15°C), and discard the soaking solution;

[0017] (2) Refining: Soybeans after soaking are refined with a pulp slag automatic separation refiner, and the amount of water added is 5 times the weight of dry beans, and water is added while refining. 8% soy milk;

[0018] (3) Cooking: Cook...

specific Embodiment approach 3

[0022] Specific embodiment three: the difference between this embodiment and specific embodiment one and two is that the cross-sectional area of the outlet of the pipeline 4 is 1:50-100 with the ratio of the cross-sectional area of the slurry tank 2, and the soybean milk is 0.20~ The pressure of 0.30Mpa is ejected from the outlet of the pipeline 4 and enters the slurry tank 2, so that the soya-bean milk and the coagulant can be brought into contact with better pressure.

[0023] The operation of realizing soymilk brewing is mainly to realize the momentum and material transfer of soymilk. The result of the momentum and material transfer of soya-bean milk is exactly to make soya-bean milk and the coagulant in the point slurry tank 2 fully mix, and finish the pulping process. To make the two more fully mixed so as to improve the product quality will be based on the guidance of the material transfer principle theory. For the ratio of the sprayed area of soybean milk within a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com