Precise decoupling detecting method for gyroscope scale factor and input shaft default angle

A technology of scaling factor and testing method, which is applied in gyro effect for speed measurement, gyroscope/steering sensing equipment, speed/acceleration/shock measurement, etc., can solve the problem of parallelism and perpendicularity errors of sensitive axes of devices, unscientific, Calculations are inaccurate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

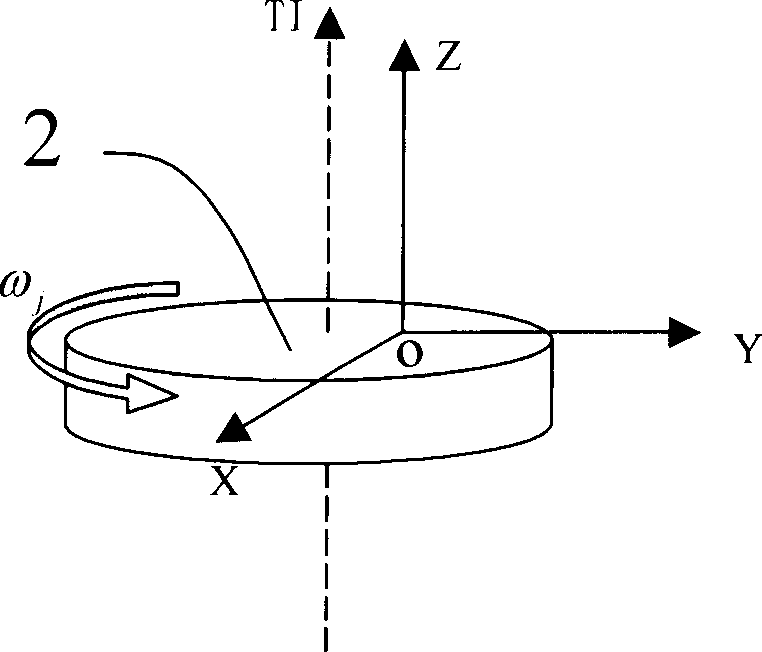

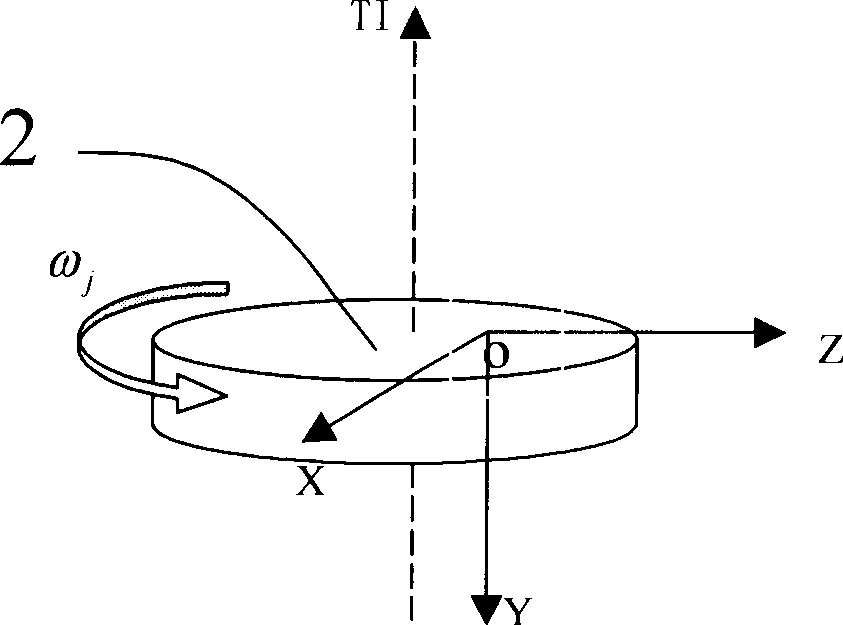

[0081] The specific implementation method of the present invention, in combination with Figure 4 , Figure 5 The details are as follows:

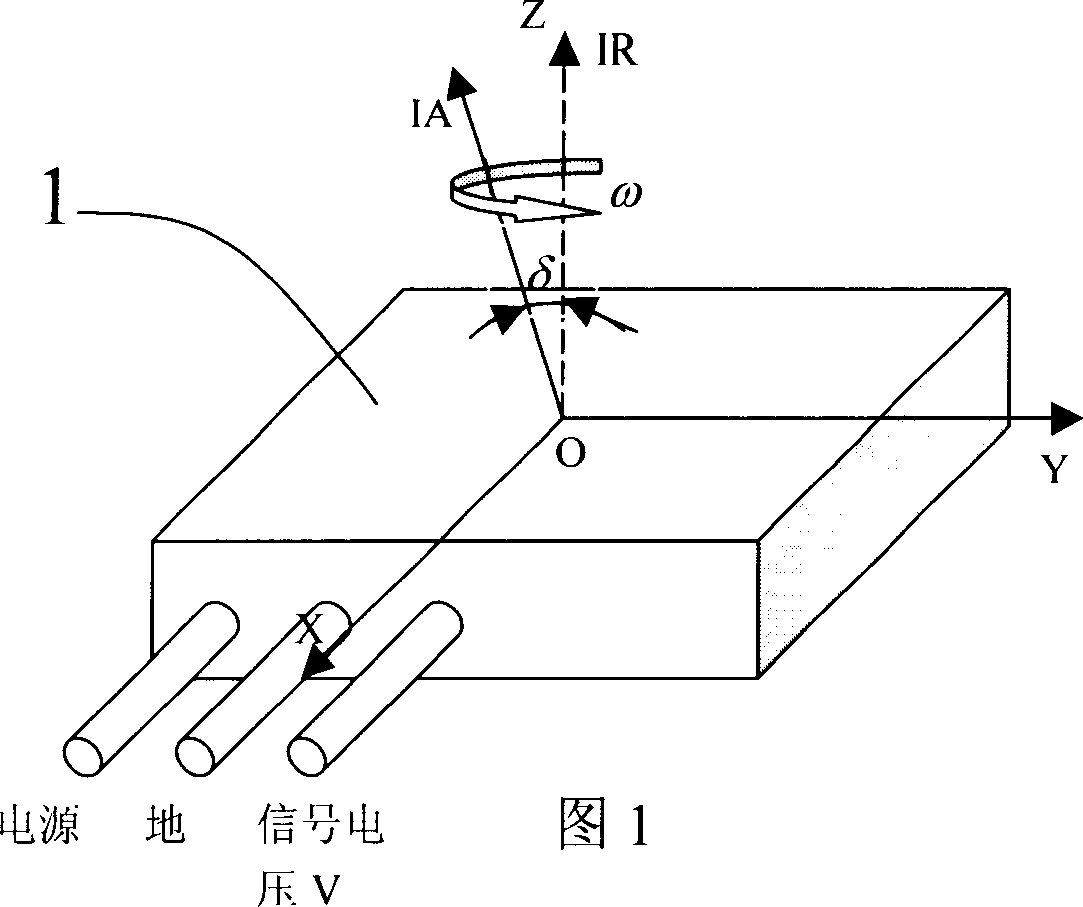

[0082] This test method includes two parts: turntable experiment and data processing. The axes of the gyroscope are specified as follows: the OZ axis coincides with the input reference axis IR, and OX and OY are perpendicular to each other in the gyroscope installation plane. Generally, OX is parallel to the output axis, and the positive directions of the three axes satisfy the requirement of OX×OY=IA Regulation;

[0083] The turntable experiment of this test method can use a three-axis turntable or a single-axis rate turntable with equipment that can provide an inclination angle. The preparation work includes the following: The ambient temperature is required to be within 15-35°C and kept relatively stable. No more than ±2°C, relative humidity between 20% and 80%, and no abnormal atmospheric pressure; the test bench is required to be i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com