Fuel supply equipment comprising a accumulation pipe recur to accumulation cover blocking

A technology of fuel supply and pressure accumulator, which is applied to fuel injection devices with fuel storage, fuel injection devices, charging systems, etc., which can solve the problems of assembling and disassembling functional units, and achieve improved accessibility and optimization Simple effect of component manufacturing, assembly/disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

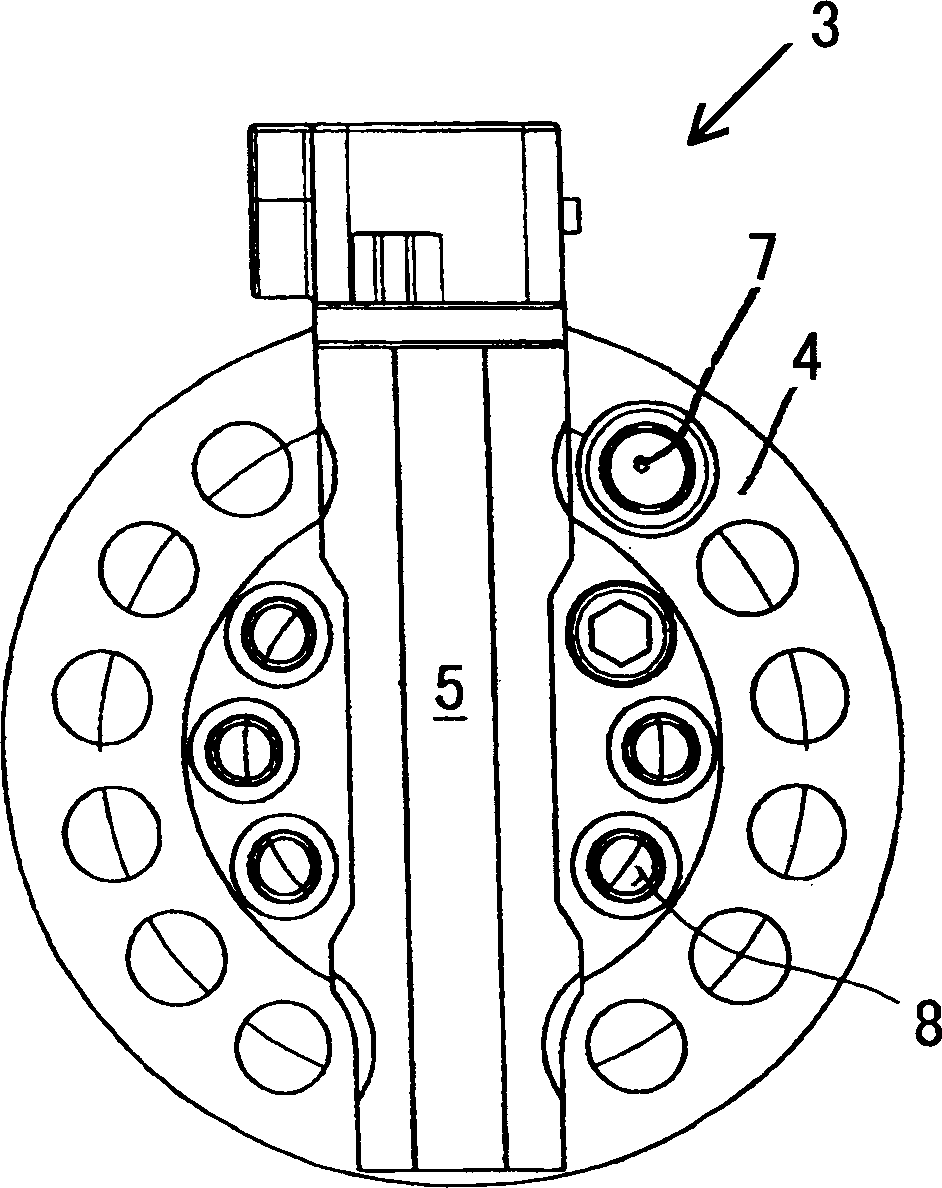

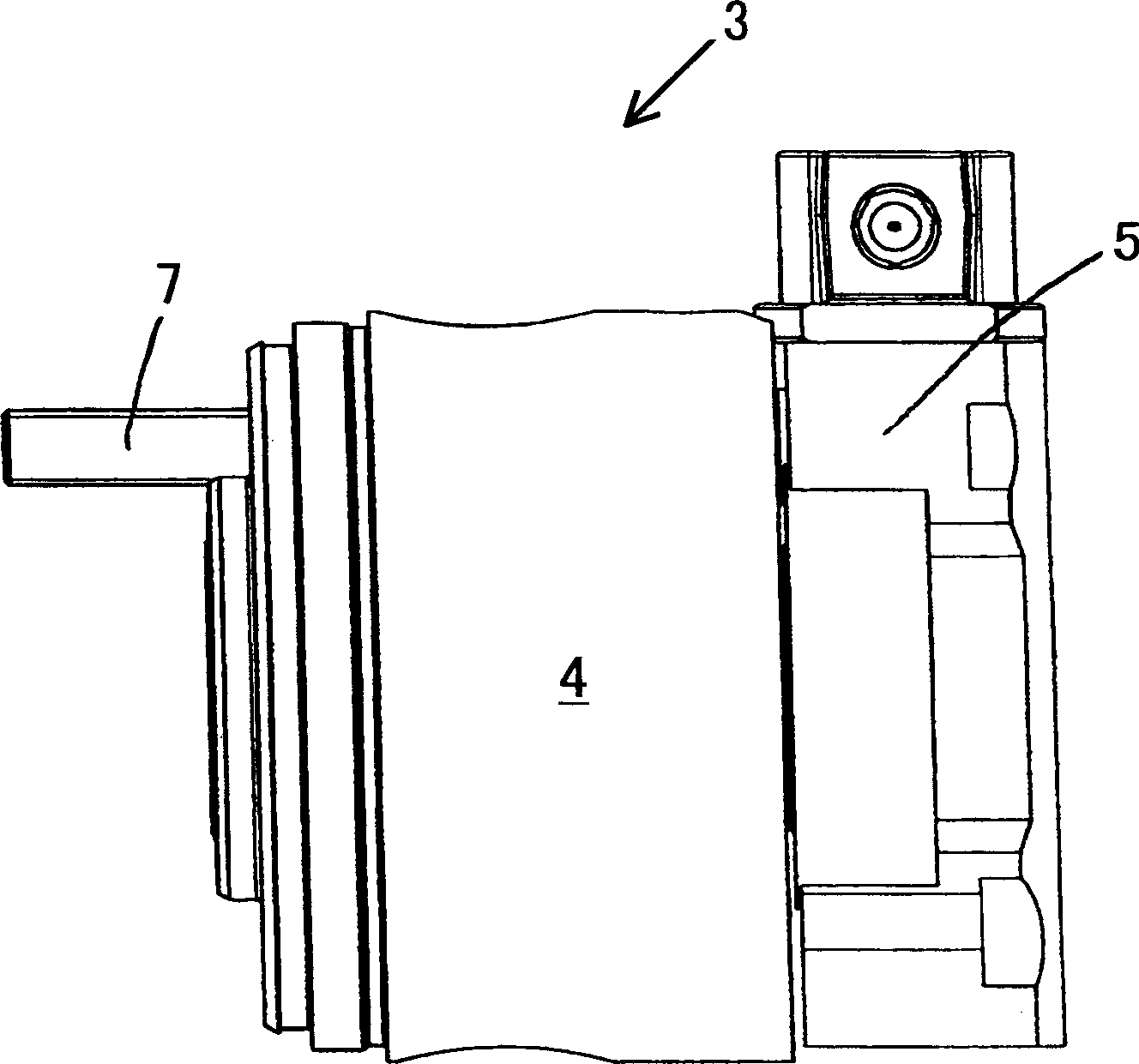

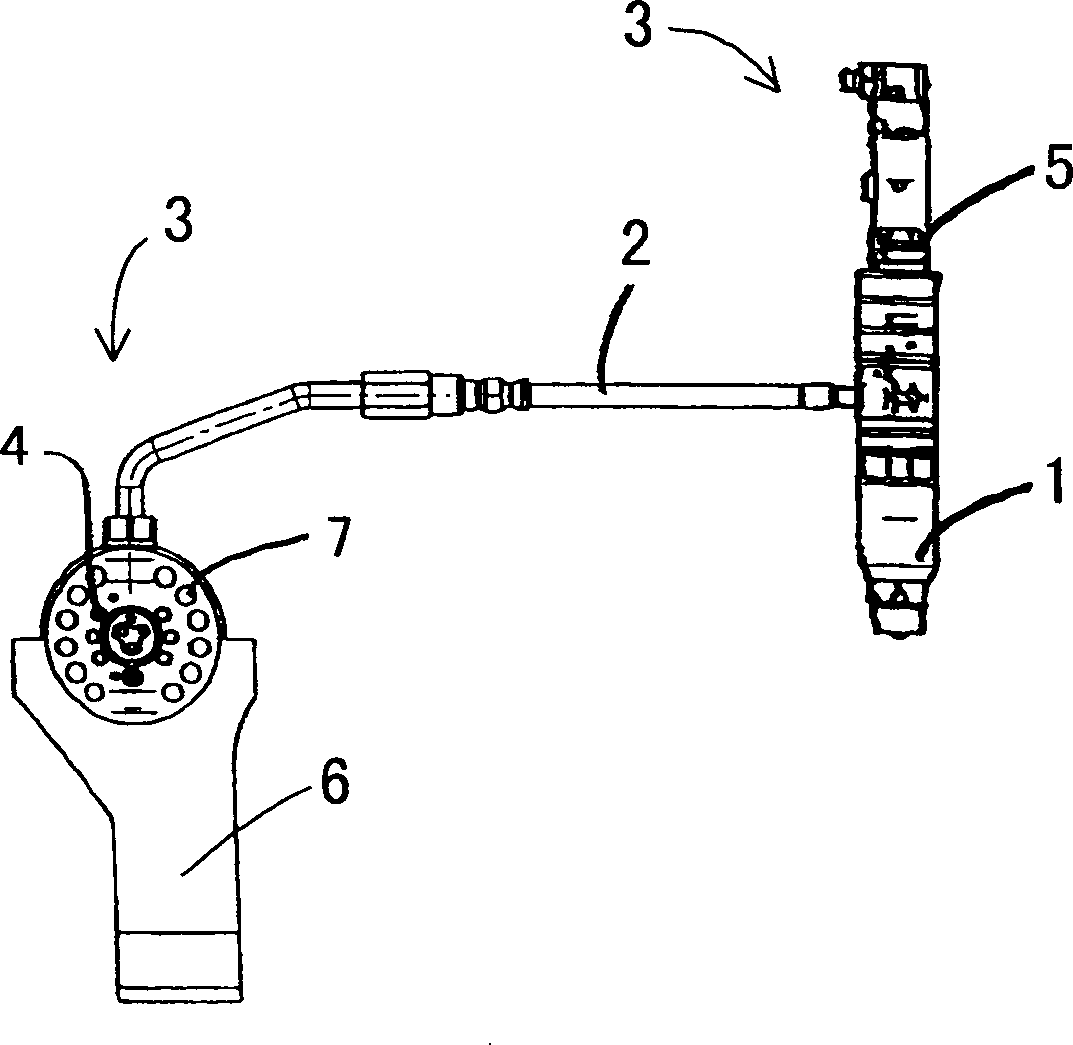

[0026] Pressure accumulator units are known to consist of pipe-like components with or without inserts, which by means of press Figures 1 to 4 The pressure accumulator covers are each sealed at the end faces and are arranged approximately at the level of the cylinder head along the internal combustion engine (not shown).

[0027] Each pressure accumulator unit is connected by means of at least one pressure line 2 to at least one injector 1 , which is usually electrically controlled.

[0028] Preferably, one pressure accumulator unit is provided for each of the two cylinders to be actuated. In the case of an odd number of cylinders, a freely positionable pressure accumulator unit operates only one cylinder. Depending on the engine type and application, the respective interconnected pressure accumulator units are charged by two to six high-pressure pumps.

[0029] As stated at the outset, the fuel enters the pressure accumulator cover 3 from the respective pressure accumulato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com