Water-cooling magnetization burning method for artist hot pot and cooker

A combustion method and stove technology, which is applied to heating fuel, household appliances, household stoves/stoves, etc., can solve problems such as bad smell, temperature drop of soup pot, and weakening of firepower, and achieve the goal of free choice of heat dissipation and coordinated heat dissipation structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

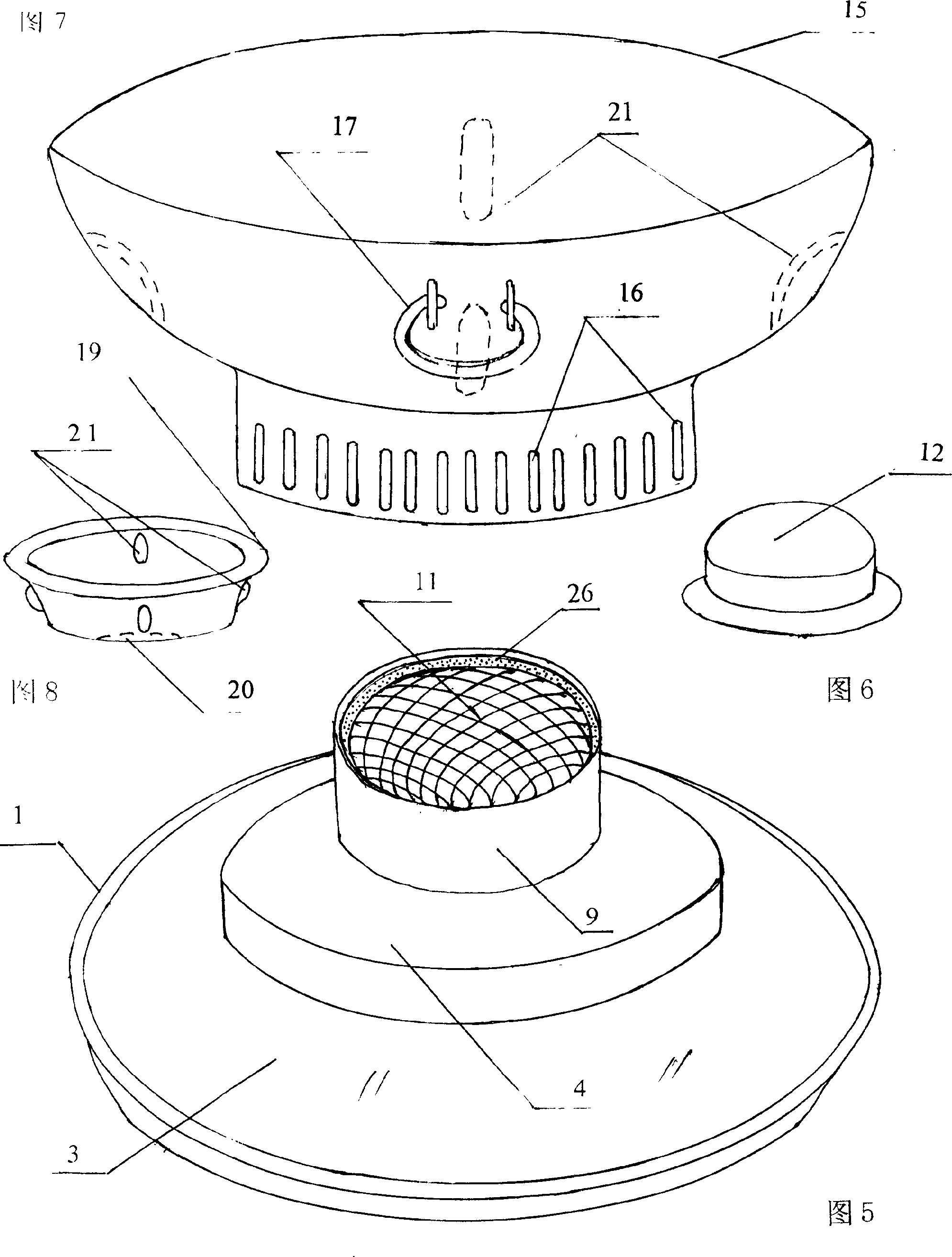

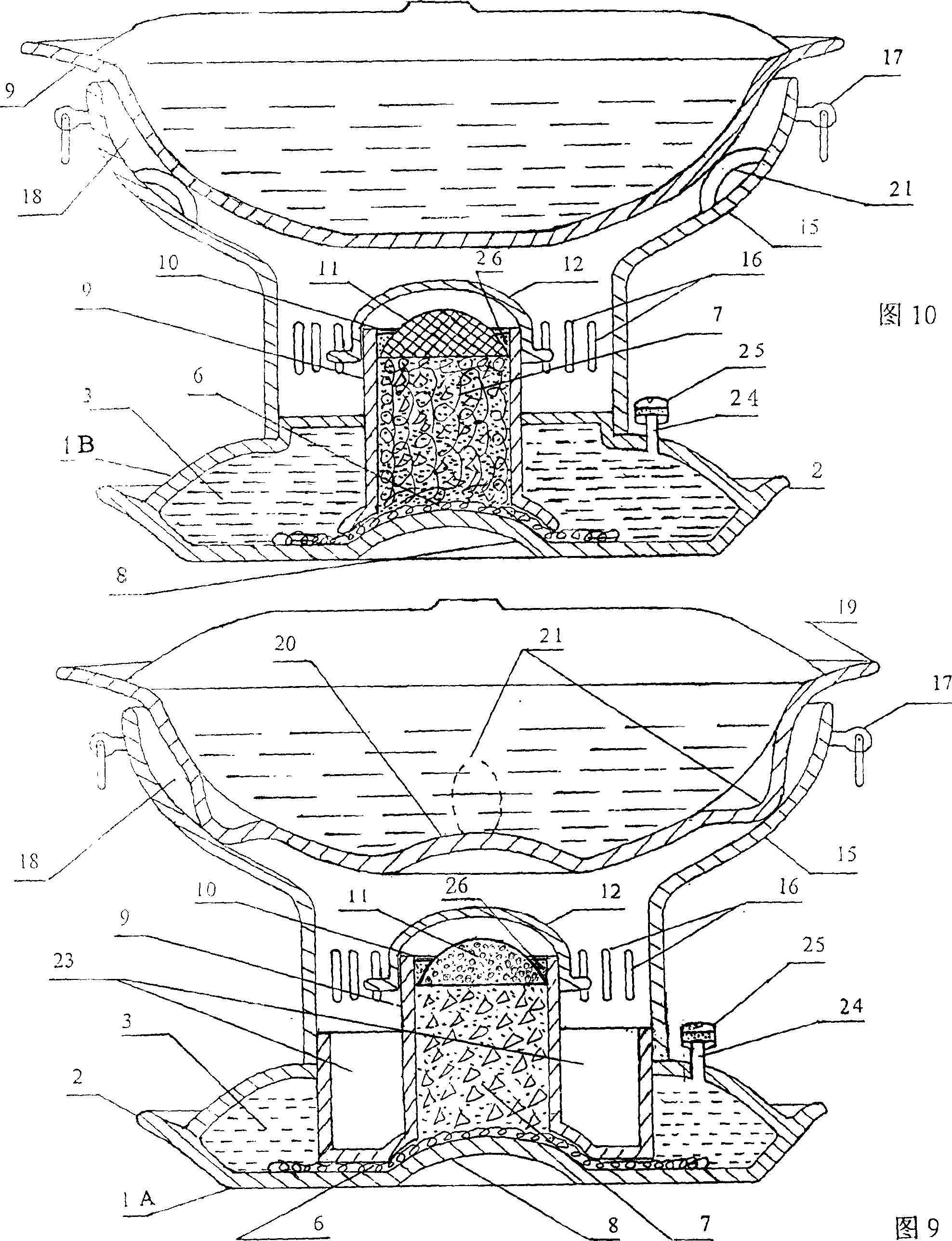

[0023] The technical solution of the present invention is shown in Fig. 1: the stove 1 is a disc-shaped shell with an end edge 2 on the outer edge, and the end edge 2 is provided to facilitate the entirety of the stove or chafing dish to be picked up or put down. In the shell of the stove 1, the inner ring surface of the fuel chamber 3 is on the same wall as the outer ring surface of the water chamber 4, the outer ring surface of the burner 9 is on the same wall as the inner ring surface of the water chamber 4, and the bottom ring surface is connected. In this way, the burner 9 and the fuel chamber 3 are separated by the annular water chamber 4 having a temperature adjustment function. The conduit 5 that is used for injecting material or balancing fuel chamber 3 normal pressures, the upper end is chewed and meshed combustion-supporting body 11 joins, and the lower end is chewed and passed water chamber 4, extends to the top in fuel chamber 3. The adsorption layer 6 with adsorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com