Vacuum processing apparatus

A technology for processing equipment and equipment, applied in vacuum evaporation plating, metal material coating process, ion implantation plating, etc., can solve the problems of maintenance and repair of negative effects inside the vacuum chamber, increased stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

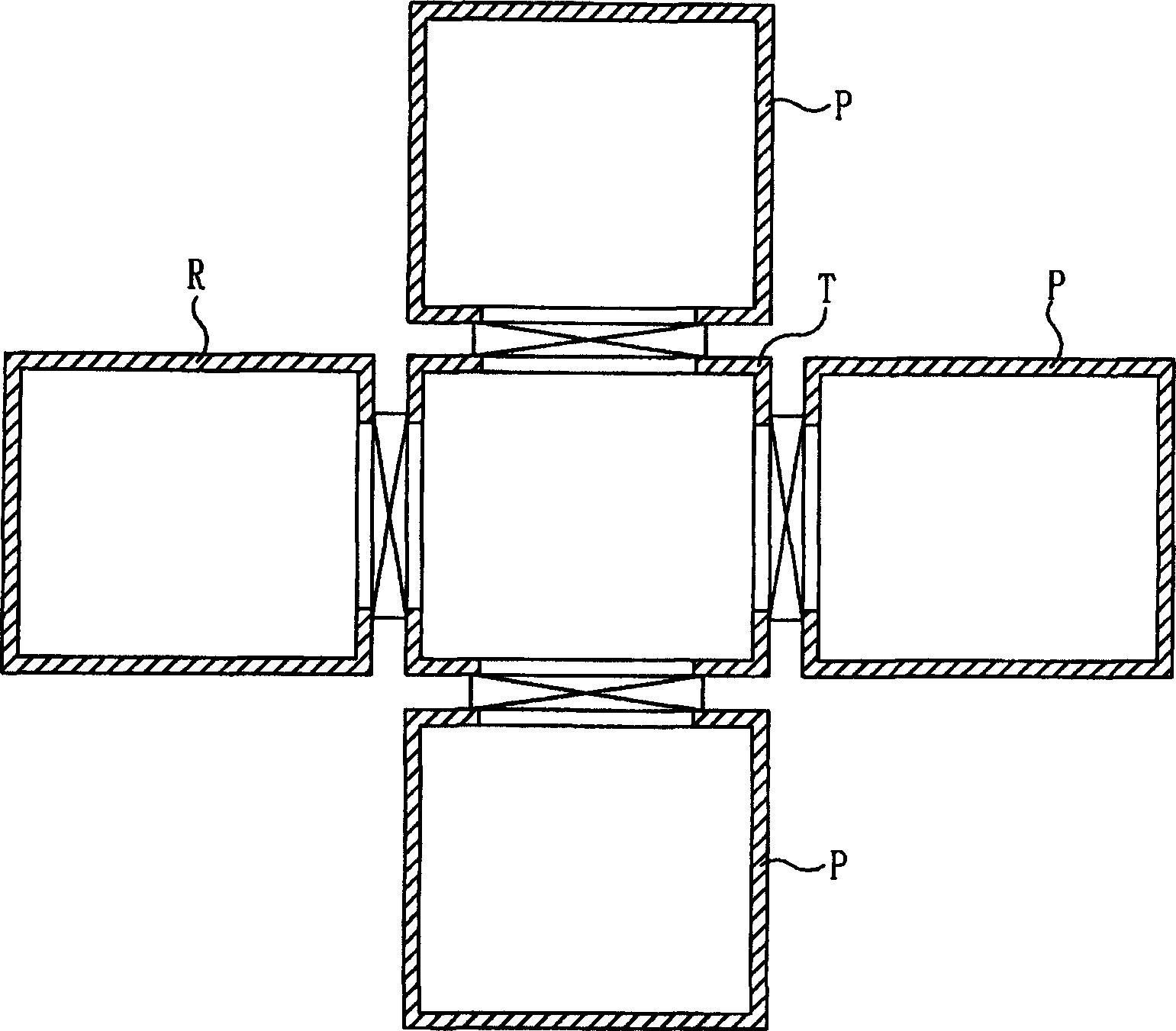

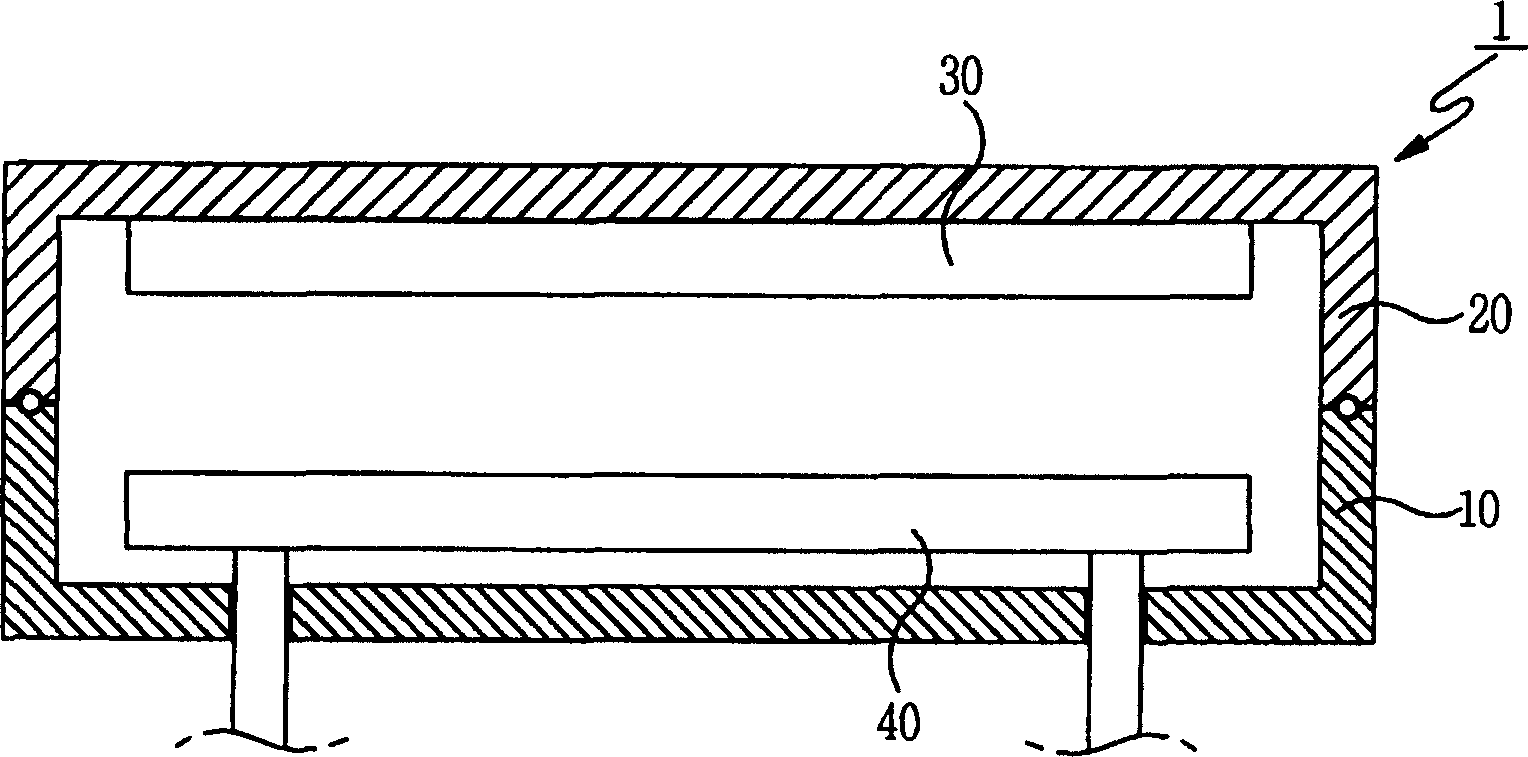

[0063] The vacuum processing apparatus according to this embodiment includes: a load lock chamber; a feed chamber; and one or more process chambers, but for convenience of description, the following description is only for one process chamber. refer to Figure 4 , The vacuum processing equipment 100 according to this embodiment includes: a chamber body 110 ; an upper cover 120 ; a horizontal driving device 140 ; an inner wall structure 150 ; and an inner wall structure lifting device 160 .

[0064] In the vacuum processing apparatus 100 according to the present embodiment, the chamber body 110 generally has a rectangular box shape, and the upper cover 120 is detachably provided on the chamber body 110 to constitute a vacuum chamber. The vacuum chamber is used to process a large-area flat panel display substrate having a rectangular shape therein, and thus generally has a rectangular box shape corresponding to the rectangular substrate. The vacuum chamber is provided with an...

no. 2 example

[0081] The vacuum processing apparatus according to the present embodiment includes: a load lock chamber; a feed chamber; and one or more process chambers, and for convenience of description, the following description is only for one process chamber. refer to Figure 9 , The vacuum processing equipment 200 according to this embodiment includes: a chamber body 210 ; an upper cover 220 ; a horizontal driving device 240 ; an inner wall structure 250 ; and an inner wall structure lifting device 260 .

[0082] In the vacuum processing apparatus 200 according to the present embodiment, the chamber body 210 generally has a rectangular box shape, and the upper cover 220 is detachably provided on the chamber body 210 to constitute a vacuum chamber. The vacuum chamber is used to process a large-area flat panel display substrate having a rectangular shape therein, and thus generally has a rectangular box shape corresponding to the rectangular substrate. The vacuum chamber is provided wi...

no. 3 example

[0100] The vacuum processing apparatus according to this embodiment includes: a load lock chamber; a feed chamber; and one or more process chambers, but for convenience of description, the following description is only for one process chamber. refer to Figure 15 , The vacuum processing equipment 300 according to this embodiment includes: a chamber body 310 ; an upper cover 320 ; a horizontal driving device 340 ; and a sealing device 350 .

[0101] In the vacuum processing apparatus 300 according to the present embodiment, the chamber body 310 generally has a rectangular box shape, and the upper cover 320 is detachably provided on the chamber body 310 to constitute a vacuum chamber. The vacuum chamber is used to process a large-area flat panel display substrate having a rectangular shape therein, and thus generally has a rectangular box shape corresponding to the rectangular substrate. The vacuum chamber is internally provided with an exhaust system (not shown) to establish a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com