Coiling apparatus of re-spooling machine

A technology of coiling device and rewinding machine, which is applied in the direction of transportation and packaging, conveying filamentous materials, thin material processing, etc. It can solve the problems of low efficiency and inability to accurately control the width adjustment value, so as to improve production efficiency and reduce The effect of operational difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

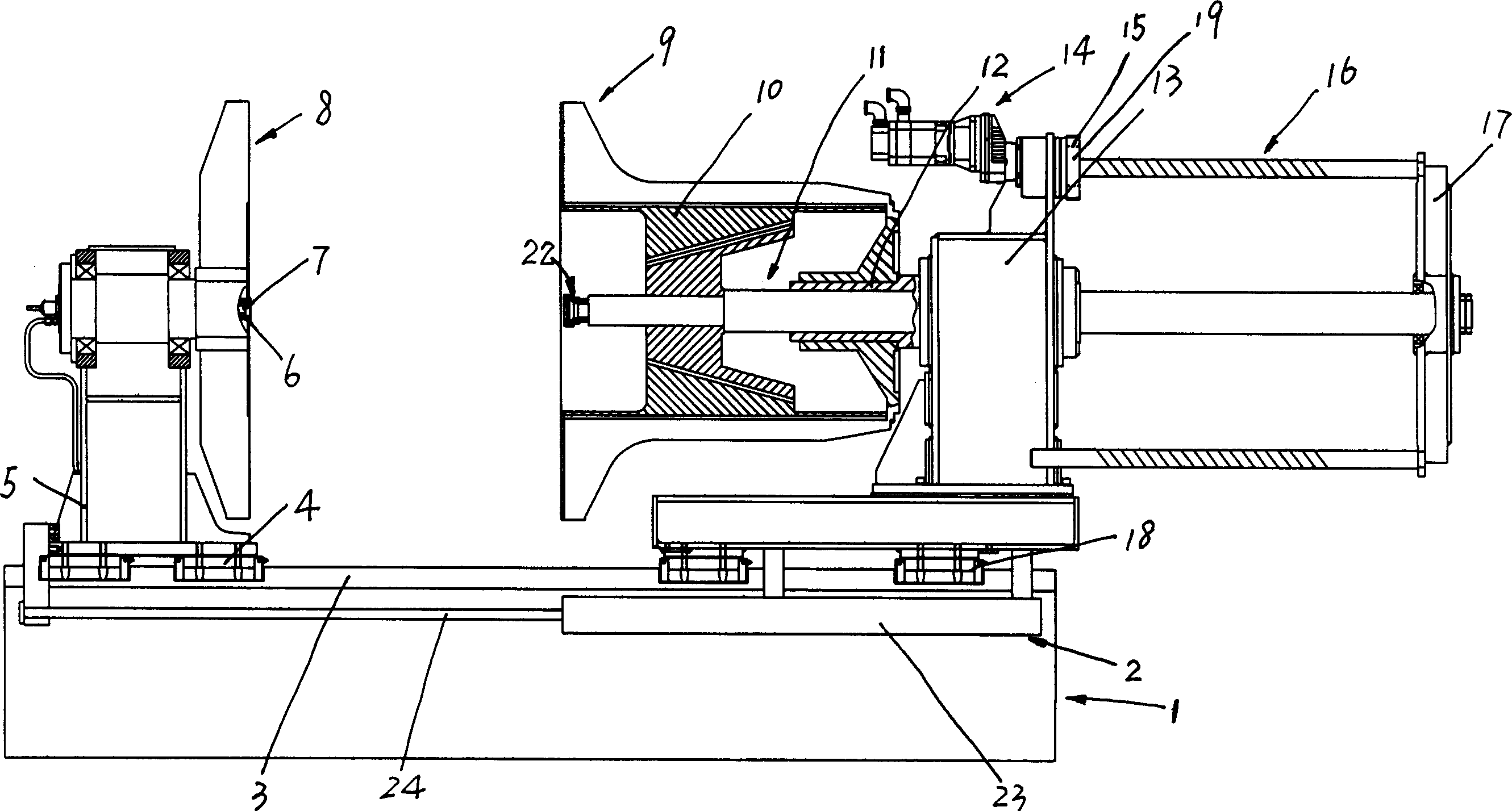

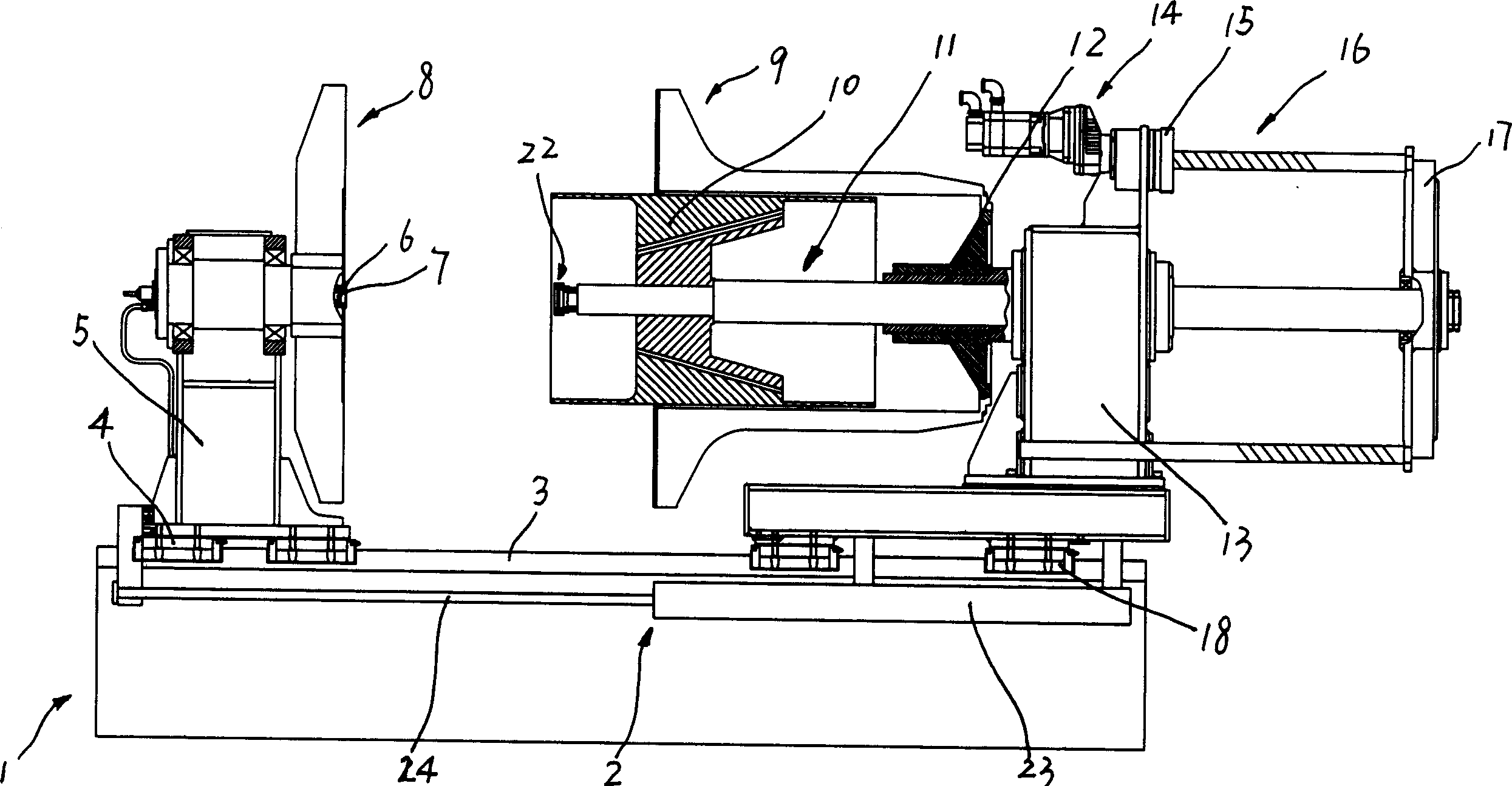

[0023] See attached figure 1 - attached Figure 8 , a winding device for a rewinding machine, which includes an underframe 1, a guide rail 3 arranged on the underframe 1, a first vertical arm 5 and a second vertical arm 13 slidably arranged on the guide rail 3, The first turntable 8 rotatably arranged on the first vertical arm 5, the second turntable 9 rotatably arranged on the second vertical arm 13, and the second turntable 9 rotatably arranged on the second vertical arm 13 The sliding shaft 11 on the top, the sliding shaft 11 is also slidably arranged relative to the second vertical arm 13 along the axial direction of the second turntable 9, and the sliding shaft 11 is locked relative to the second turntable 9, the second The vertical arm 13 is provided with a main shaft sleeve 12, the sliding shaft 11 is rotatably inserted in the main shaft sleeve 12, and the sliding shaft 11 and the main shaft sleeve 12 are relatively detented, and the second turntable 9 is fixedly arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com