Integrated continuous construction system device for large-scale concrete engineering

A system device and concrete technology, which is applied in water conservancy projects, artificial waterways, buildings, etc., can solve problems such as increased project investment costs, difficult construction progress control, and poor stability of project quality, so as to reduce operating costs, shorten the time for laying materials, shorten The effect of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

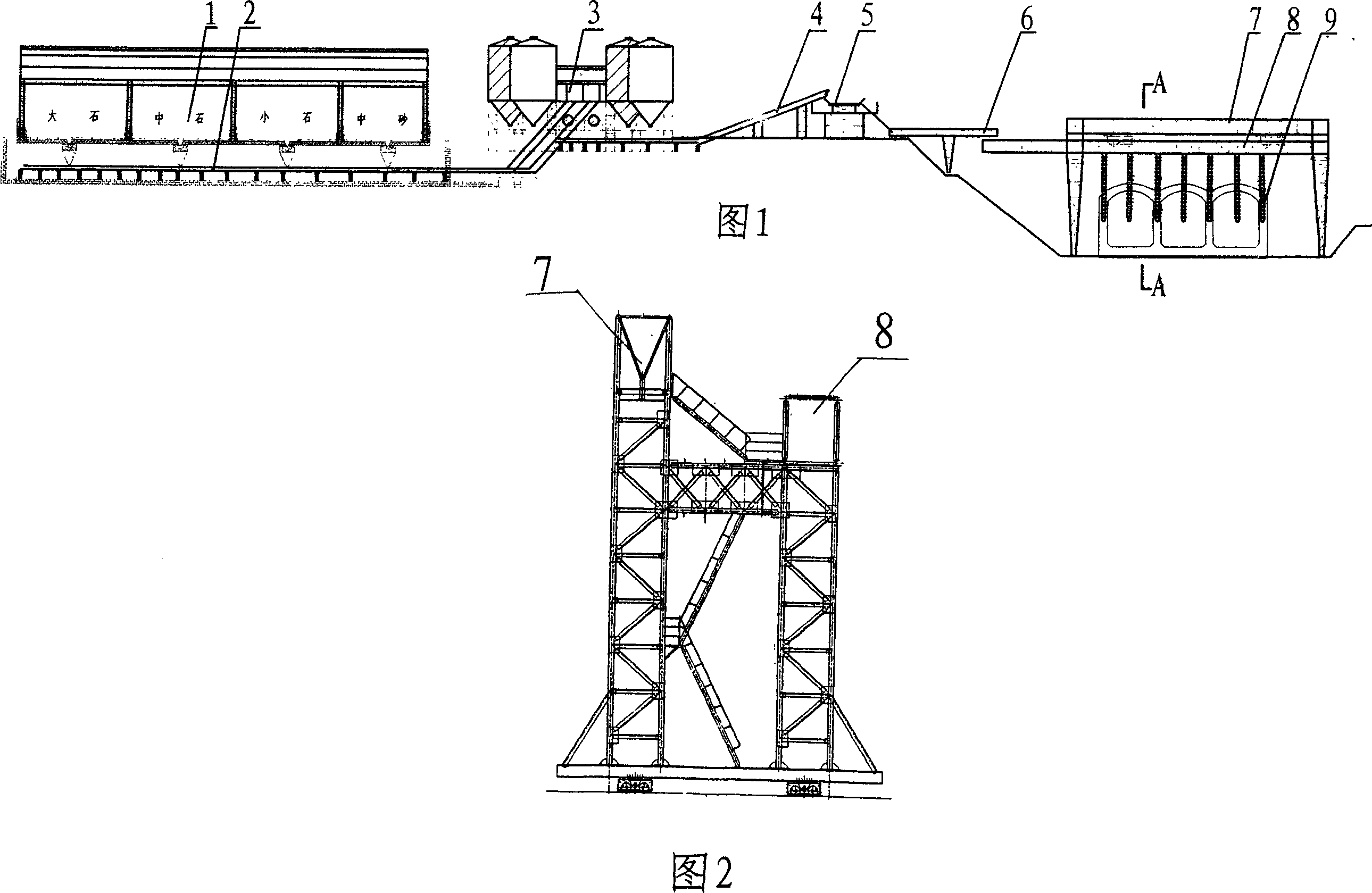

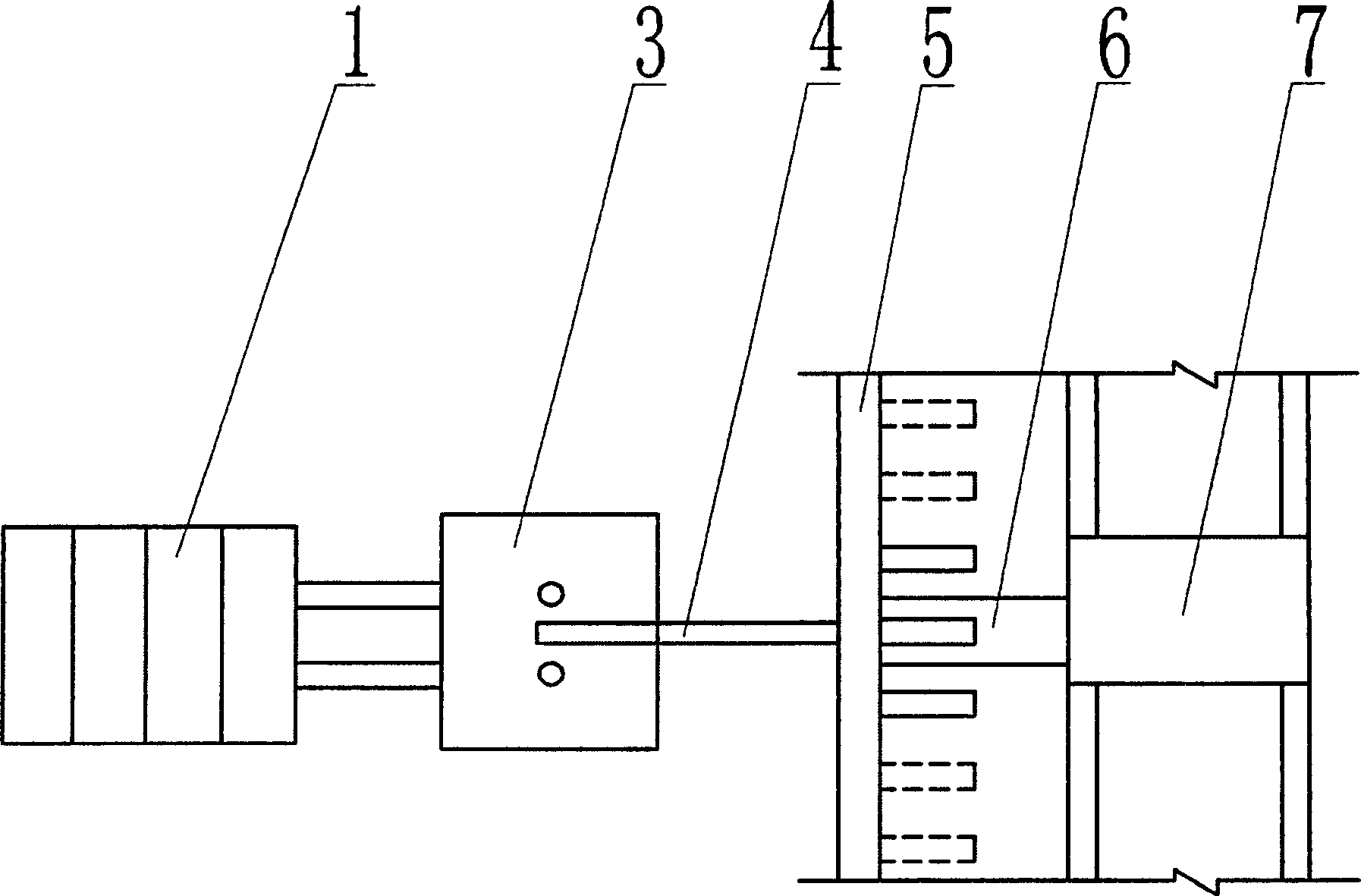

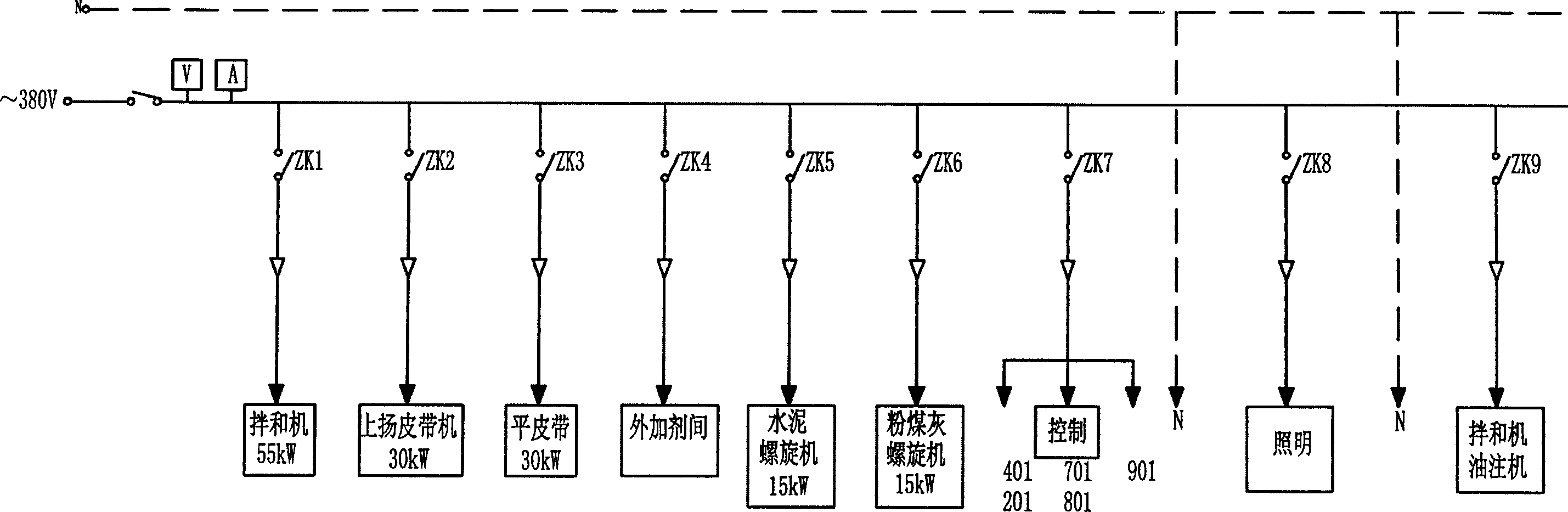

[0029] See Figure 1- Figure 6 , large-scale concrete arch culvert construction, due to the large construction warehouse surface, high concrete pouring volume, wide contact surface with air (20×25m), the construction is difficult, especially in high temperature seasons, the concrete surface in the warehouse evaporates and slumps The loss of strength is faster, the "aging" of concrete is accelerated, and early hardening, cold joints, and poor bonding between layers are prone to occur. In order to meet the needs of on-site pouring, the present invention adopts an integrated new construction technology to solve the problem. The specific design is: (1) Choose the best raw material suppliers to ensure the smooth supply of arch and culvert construction logistics. Through automatic feeding of warehouse aggregates and ground ridges, various raw materials are sent to the mixing building. (2) Automatic feeding, automatic weighing, concrete production and system controlled by computer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com