Thin sheet-like article displacement detection method and displacement correction method

A detection method, a thin-plate technology, applied in the direction of conveyor objects, transportation and packaging, lighting and heating equipment, etc., can solve the problems of difficult motion control, separate costs, complex mechanisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

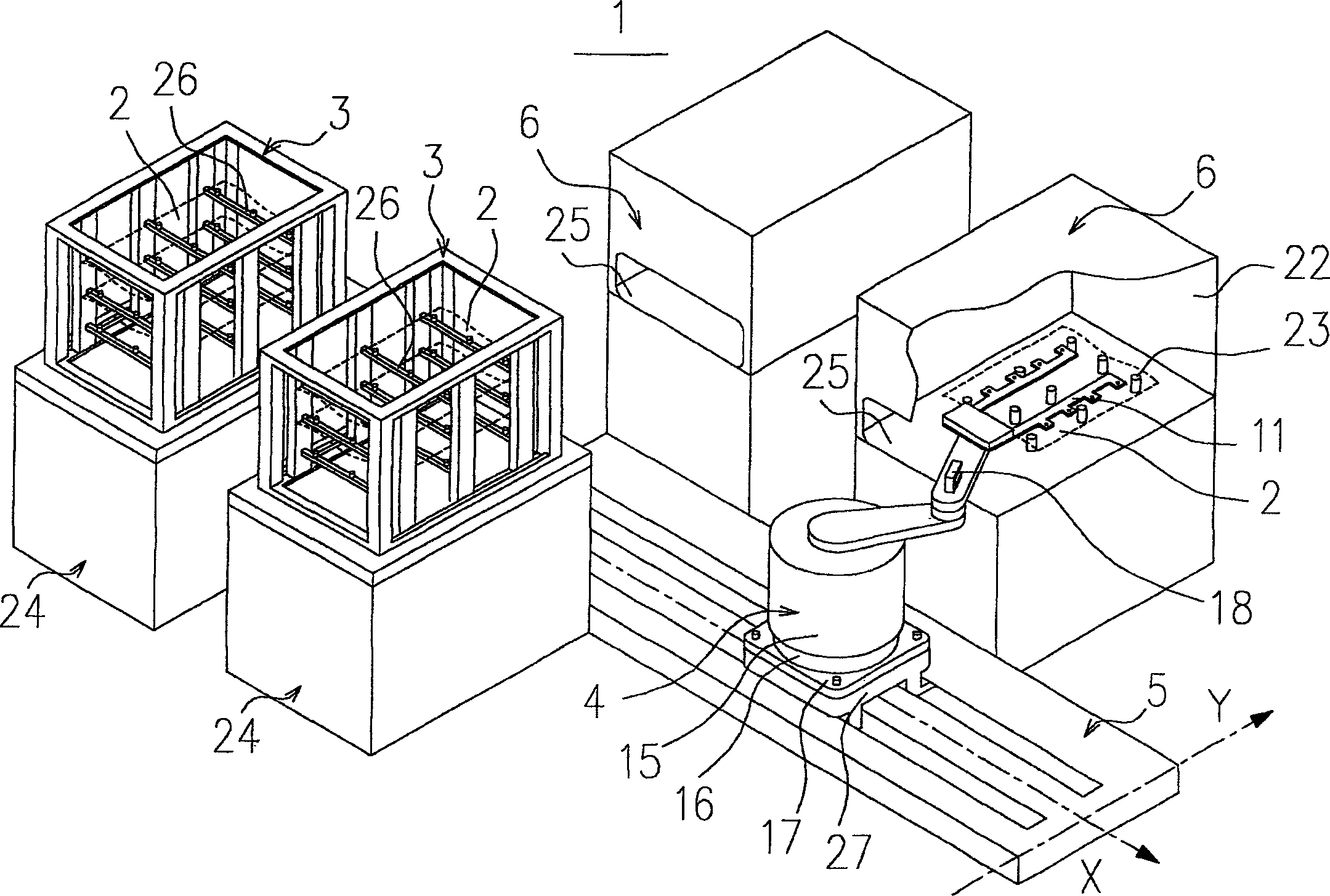

[0037] figure 1 pass for pair Figure 13 And described the present applicant's existing example to improve the operating device 1, the improvement point of the present invention is to remove the detection mechanism 18 that is arranged on the front of the processing device 6 and on the linear motion mechanism 5, that is, the detection mechanism is a unique U The font is arranged on the support arm 14 .

[0038] Preferred embodiments of the present invention are described below. In addition, the following examples are not intended to limit the scope of the present invention. Therefore, those of ordinary skill in the art can employ other embodiments within the scope of the principles of the invention.

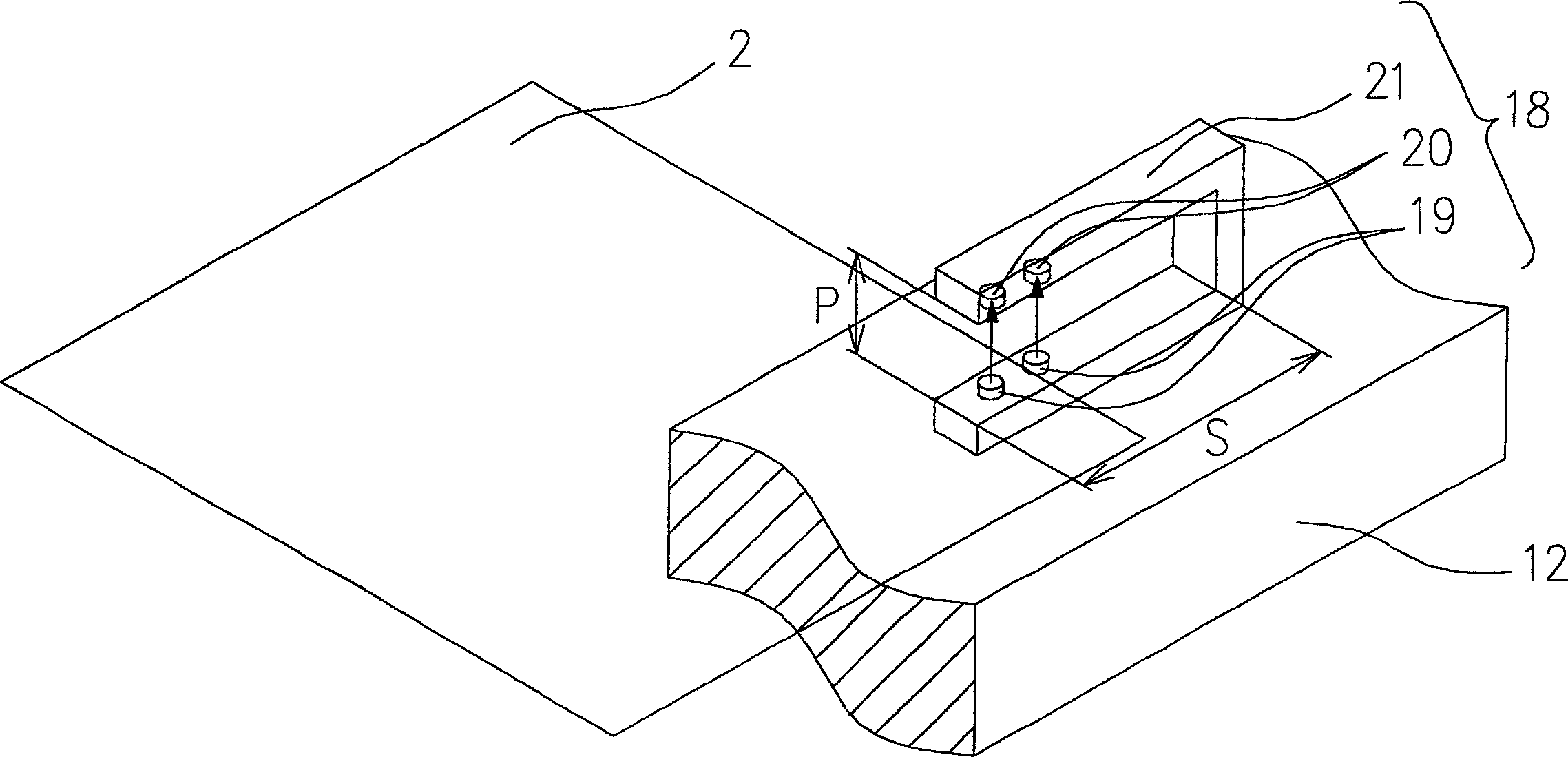

[0039] figure 2 It is a partially enlarged perspective view of the detection mechanism 18 of the present invention. In this detection mechanism 18, a light projector 19 and a photoreceptor 20 are provided near the front end of a fixed member 21 having a flat opening and a de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com