Refrigerator

A technology for refrigerators and cabinets, which is applied to lighting and heating equipment, cooling fluid circulation devices, household appliances, etc., and can solve problems such as conflicts between defrosting and cooling, energy consumption reduction for evaporator defrosting, and heating power loss. Achieve the effect of reducing refrigeration operation loss, stable defrosting work, and maintaining freshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in detail below in conjunction with the accompanying drawings.

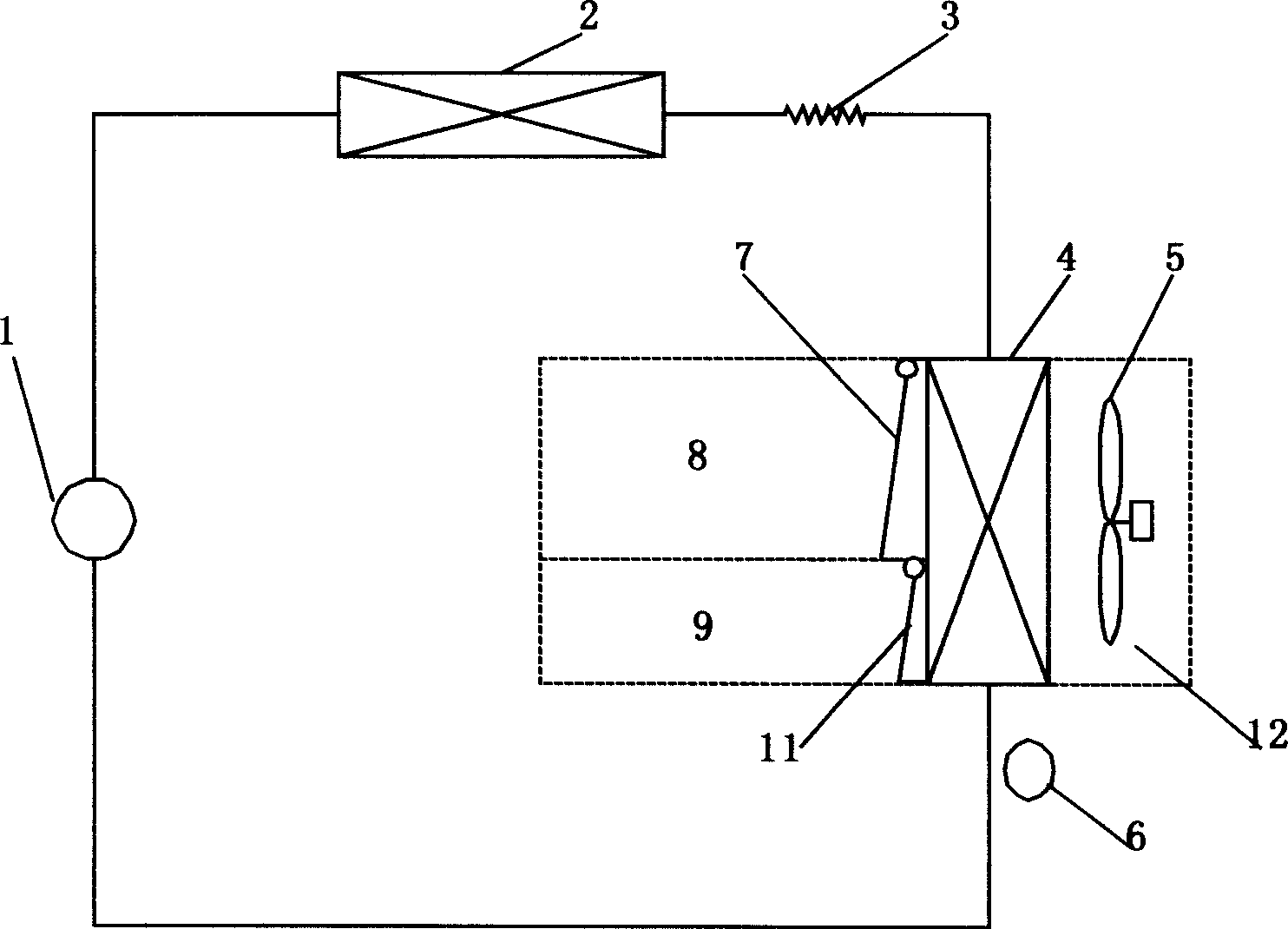

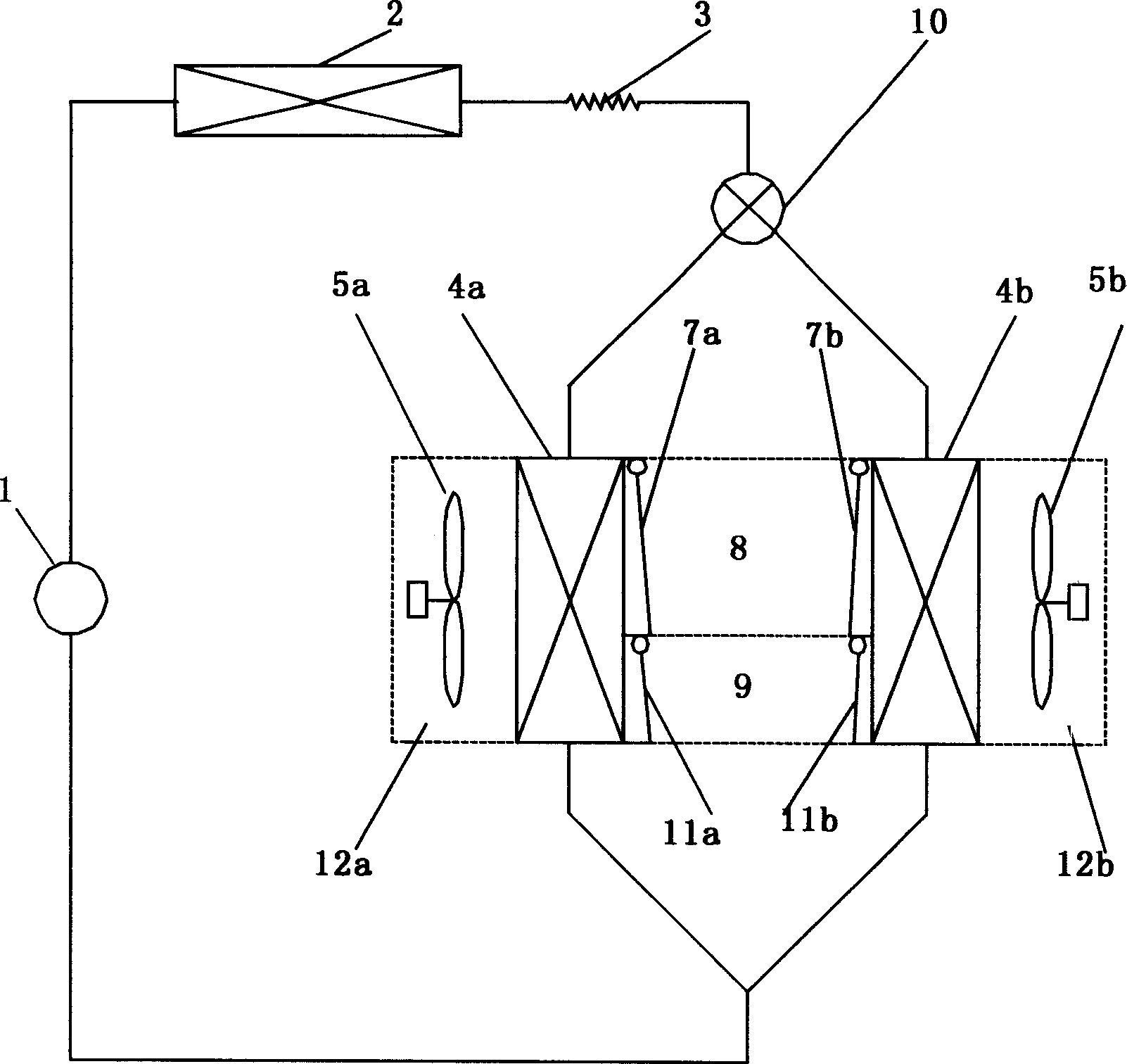

[0051] figure 2 It is a schematic flow chart of the refrigerator refrigeration cycle of the present invention. For simplicity and clarity, the present invention will be described in detail using a refrigerator having a refrigerating compartment and a freezing compartment.

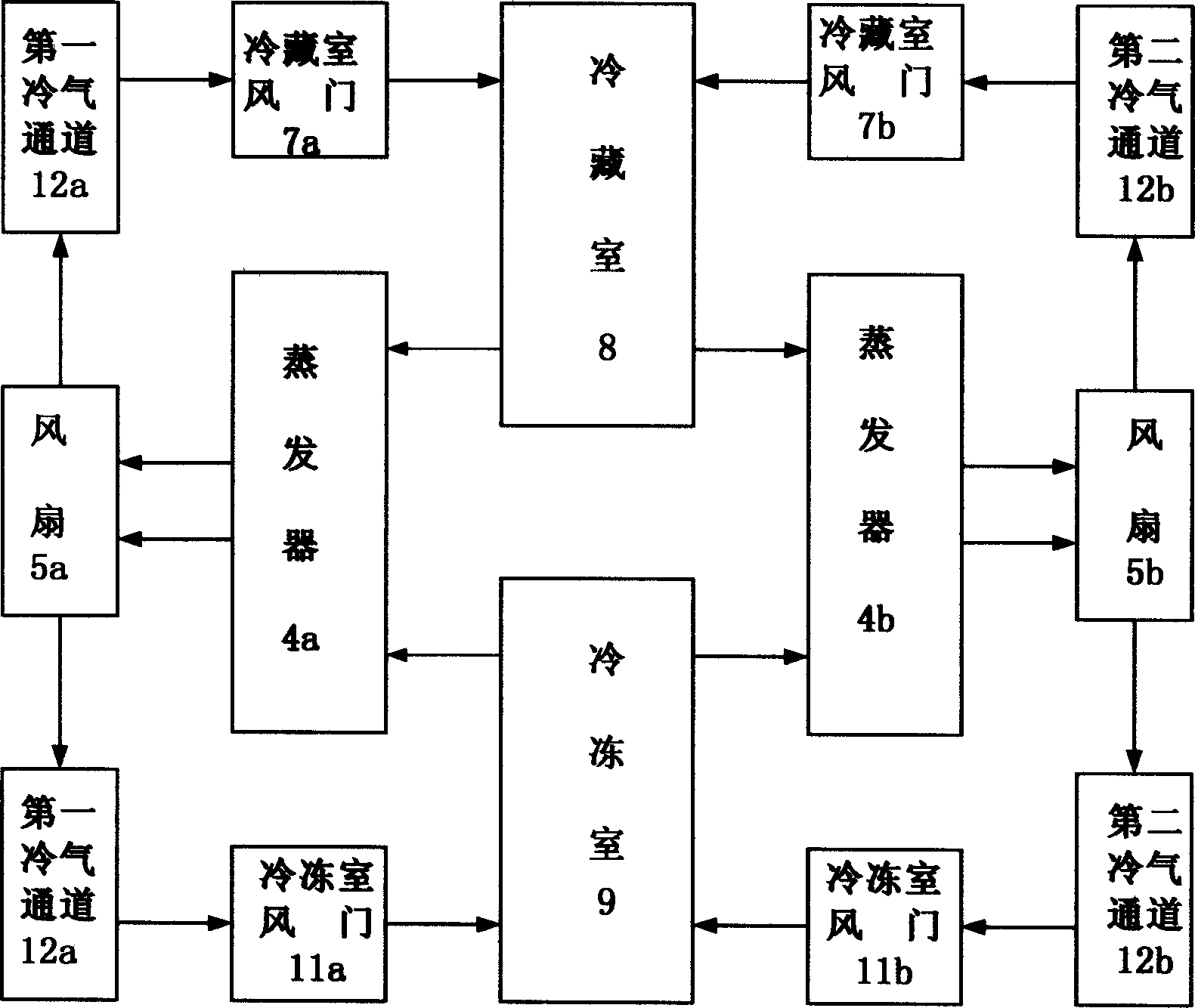

[0052] Such as figure 2 As shown, the refrigerant is driven by the compressor 1 and flows through the condenser 2 and the capillary tube 3. The output end of the capillary tube 3 is connected to the input port of the solenoid valve 10 to control the flow of the refrigerant from the two output ports of the solenoid valve 10. The evaporator 4a and the evaporator 4b, the refrigerant flows into the compressor 1 from the combination of the output ends of the evaporator 4a and the evaporator 4b, the above constitutes the refrigeration cycle of the refrigerator of the present invention.

[0053] Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com