Method and apparatus for removing viscous ash deposit in boiler

A kind of ash accumulation and boiler technology, which is applied in the direction of combustion method, removal of solid residue, and treatment of combustion products, etc. It can solve the problems of poor removal effect, high cost of ash removal, easy adhesion of steel balls and viscous ash accumulation, etc., to achieve The method is simple and flexible, the cost of ash removal is increased, and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

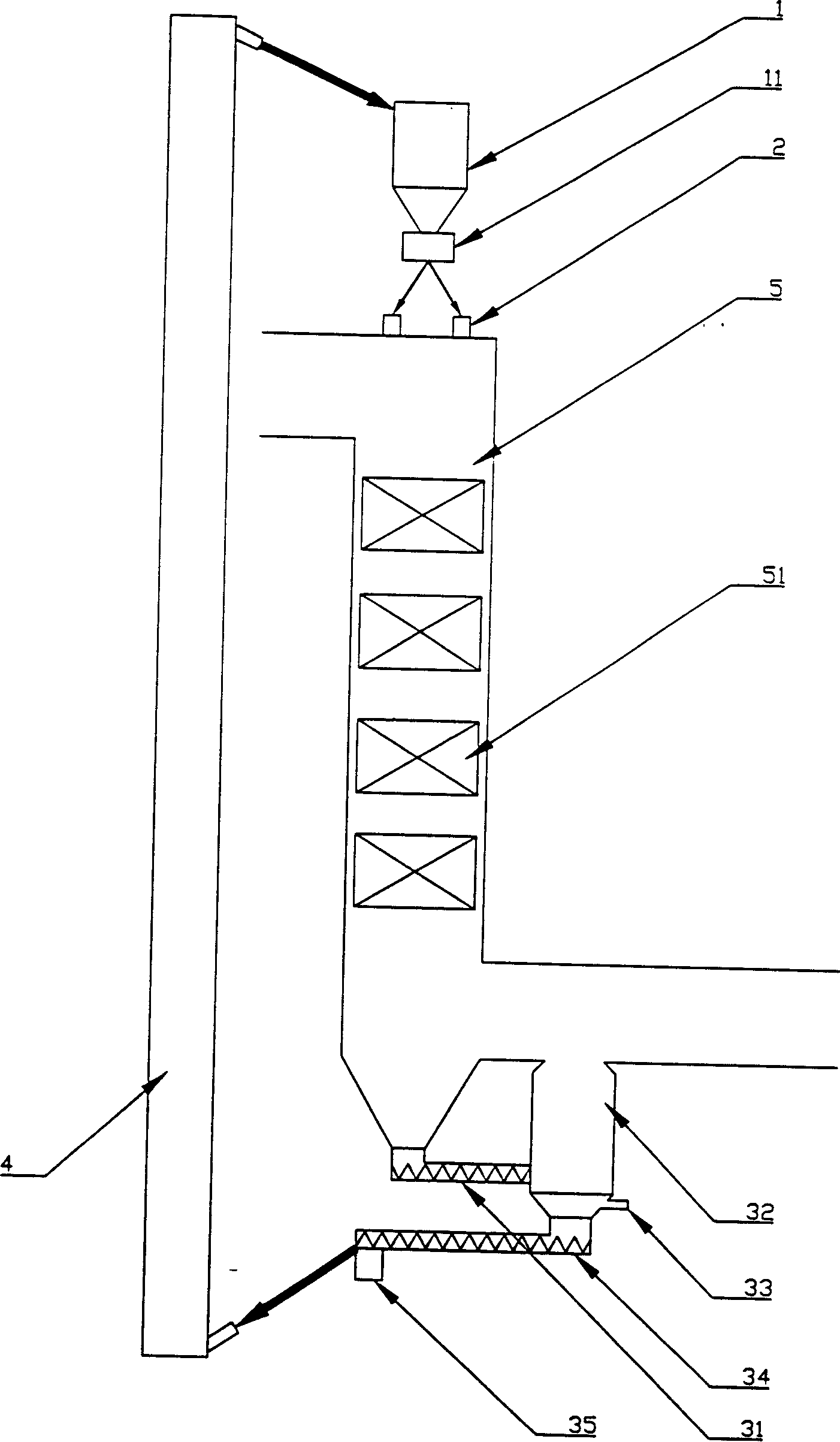

Embodiment 1

[0025] In a circulating fluidized bed boiler, there are eight particle inlets 2 on the top of the tail flue 5, all of which are connected to the hopper 1 through the particle addition control device 11; after the particles are added to the tail flue 5 from the particle inlet 2, they Flush the tube bundle 51 to take away the ash accumulated on the tube bundle 51; the particles and ash are deposited at the bottom of the tail flue 5, and are fed into the fluidization chamber 32 through the feeding screw feeder 31, and the air flows from the fluidization air inlet 33 at the bottom of the fluidization chamber 32 Enter the fluidization chamber 32 to fluidize the particles and the accumulated ash washed down. The ash is lighter and smaller, and enters the rear section of the tail flue from the top of the fluidization chamber together with the fluidization air, and the particles are discharged from the bottom of the fluidization chamber. The screw feeder 34 feeds the particle return de...

Embodiment 2

[0027] For a biomass-fired boiler, there are four particle inlets on the top of the tail flue 5, all of which are connected to the hopper 1 through the particle addition control device 11; The tube bundle 51 takes away the ash accumulation on the tube bundle 51; the particles and ash are deposited at the bottom of the flue, and are sent to the fluidization chamber 32 through the feeding screw feeder 31. Due to the high tar content in the ash produced by biomass incineration, the particles and ash The ash is bonded and discharged through the bypass outlet 35 at the outlet of the discharge screw feeder 34, and is not sent to the particle sorting device and the particle return device 4; new particles need to be added to the hopper 1. Particles use river sand with a particle size of 0.5-4mm. The ash removal system operates intermittently.

Embodiment 3

[0029] A garbage incinerator, the top of the tube-type waste heat boiler has two particle inlets 2, both of which are connected to the hopper 1 through the particle dosage control device 11; after the particles are added to the tail flue from the particle inlet 2, the tube bundle is washed with the flue gas 51, take away the ash accumulation on the tube bundle 51; the particles and ash are deposited at the bottom of the flue, and are sent into the fluidization chamber 32 through the feeding screw feeder 31, and the air enters the fluidization chamber 32 from the fluidization air inlet 33 at the bottom of the fluidization chamber , to fluidize the particles and the accumulated ash washed down. The ash is lighter and smaller, and enters the rear section of the tail flue from the top of the fluidization chamber together with the fluidization air, and the particles are discharged from the bottom of the fluidization chamber and passed through the discharge screw feeder 34 The partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com