Non-circular container possessing safety annular band

A safety loop, non-circular technology, applied in the field of containers, can solve the problems of wasting resources, unable to tear off the safety loop 128 smoothly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

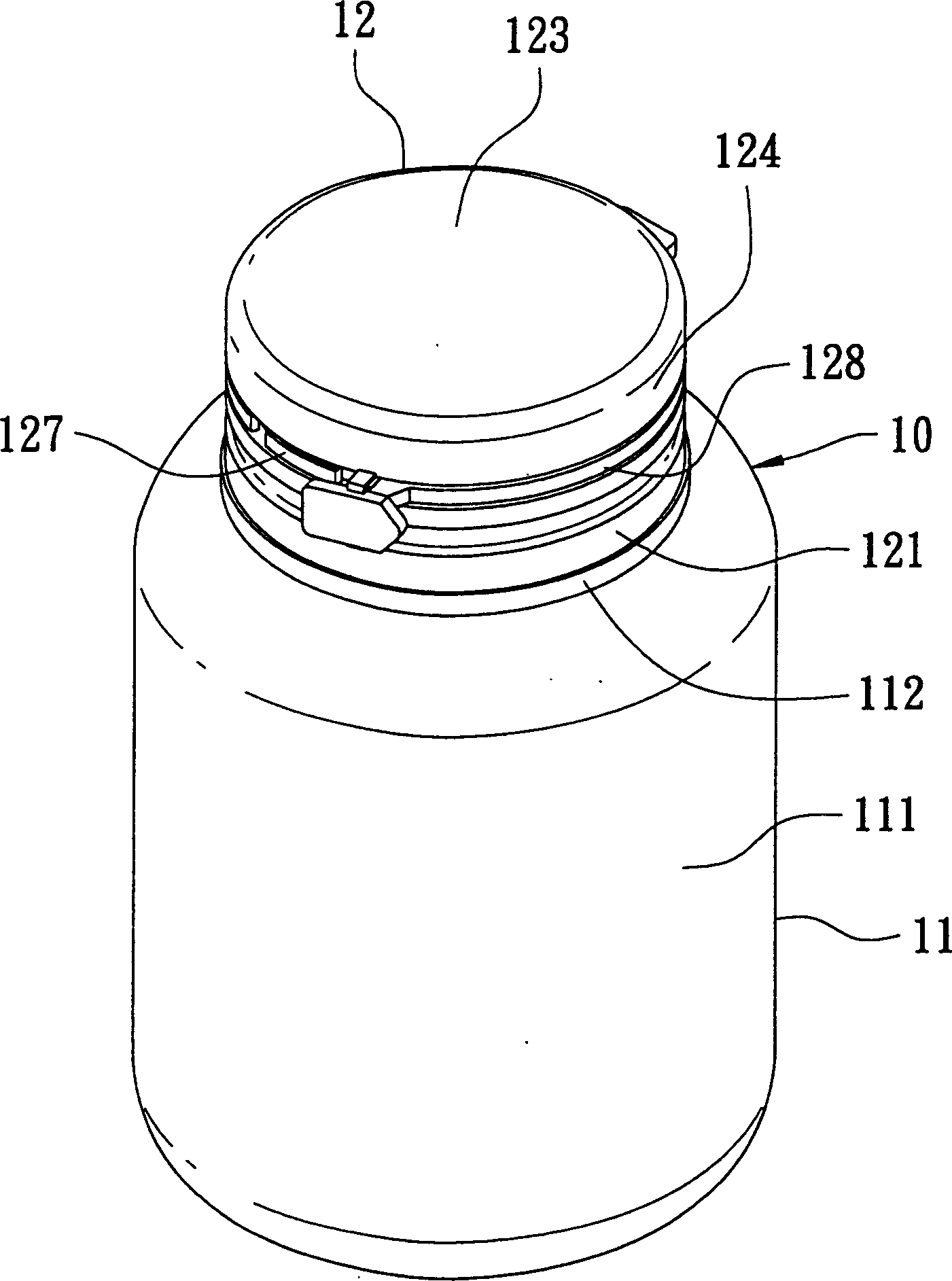

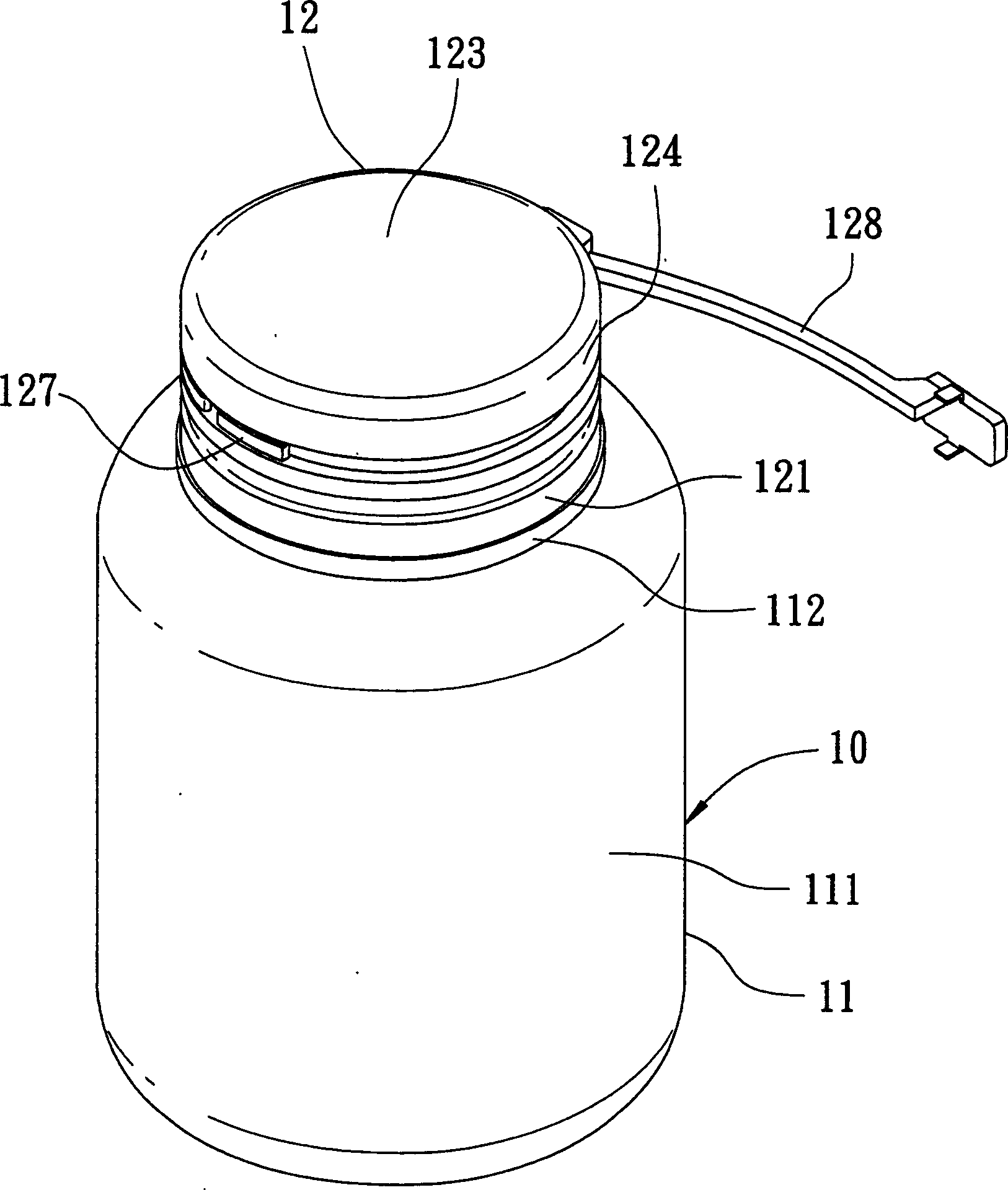

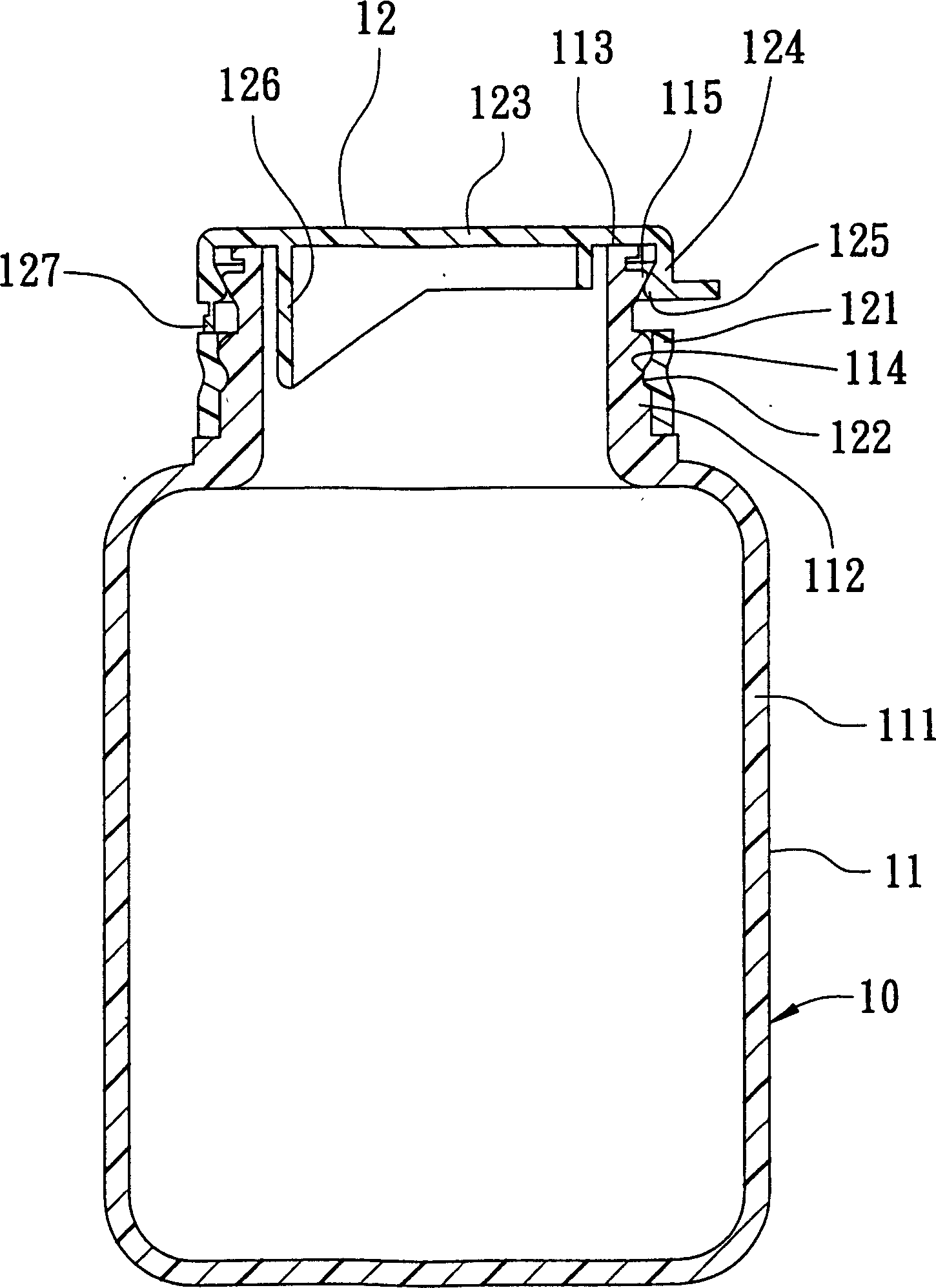

[0028] The aforementioned and other technical contents, features and effects of the non-circular container with safety ring of the present invention will be clearly understood in the following detailed description of the two preferred embodiments with reference to the accompanying drawings.

[0029] It should be noted that the relative positional terms used throughout the specification, such as "top" and "bottom", are based on the normal placement of the container, that is, Figure 5 The orientation shown is used, and similar elements are described with the same reference numerals.

[0030] Such as Figure 5 , 6, and 7, the first preferred embodiment of the non-circular container with a safety ring of the present invention includes a tank body 20, a cover body 30 that can cover the tank body 20, and is respectively arranged on the tank body 20. A first fastening assembly 40 and a second fastening assembly 50 between the body 20 and the cover 30 .

[0031] The tank body 20 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com