Press cylinder

A printing cylinder and cylinder technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of unguaranteed reliability of folding claws or pin rods, unfavorable printing cylinders, and the influence of slip rings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

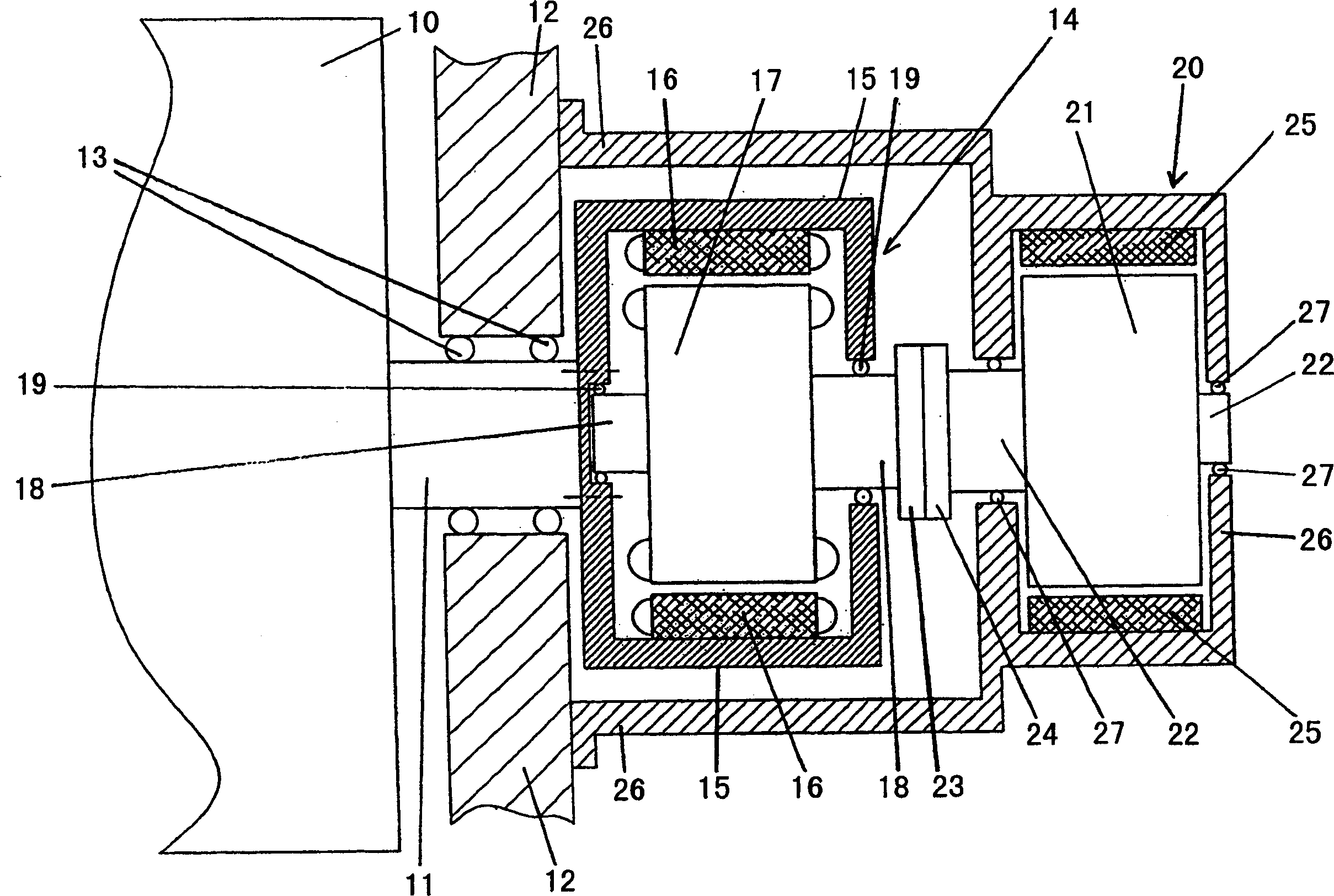

[0011] In the text below, reference will be made to figure 1 The present invention will be described in detail. figure 1 A detail of a printing cylinder 10 is shown, the shaft 11 of which is mounted on a fixed frame 12 . The printing cylinder 10 and its shaft 11 rotate relative to a fixed frame 12 in which a bearing 13 for mounting the shaft 11 of the printing cylinder 10 is mounted.

[0012] At least one drivable device, not shown in the figures, is accommodated in the printing cylinder 10 . If the printing cylinder 10 is designed as a folding claw cylinder of a printing folding unit, a plurality of driveable devices designed as folding claws are integrated in the printing cylinder. On the other hand, if the printing cylinder 10 is designed as a pin cylinder of a printing and folding unit, the driveable means integrated in the printing cylinder are the pins and the folding flaps. On the other hand, if the printing cylinder 10 is designed as a forme cylinder, the drivable d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com