Working model simulating production process and simulating method thereof

A technology of production process and operation model, applied in the field of operation simulation model, which can solve the problem of small change elasticity of simulation model

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

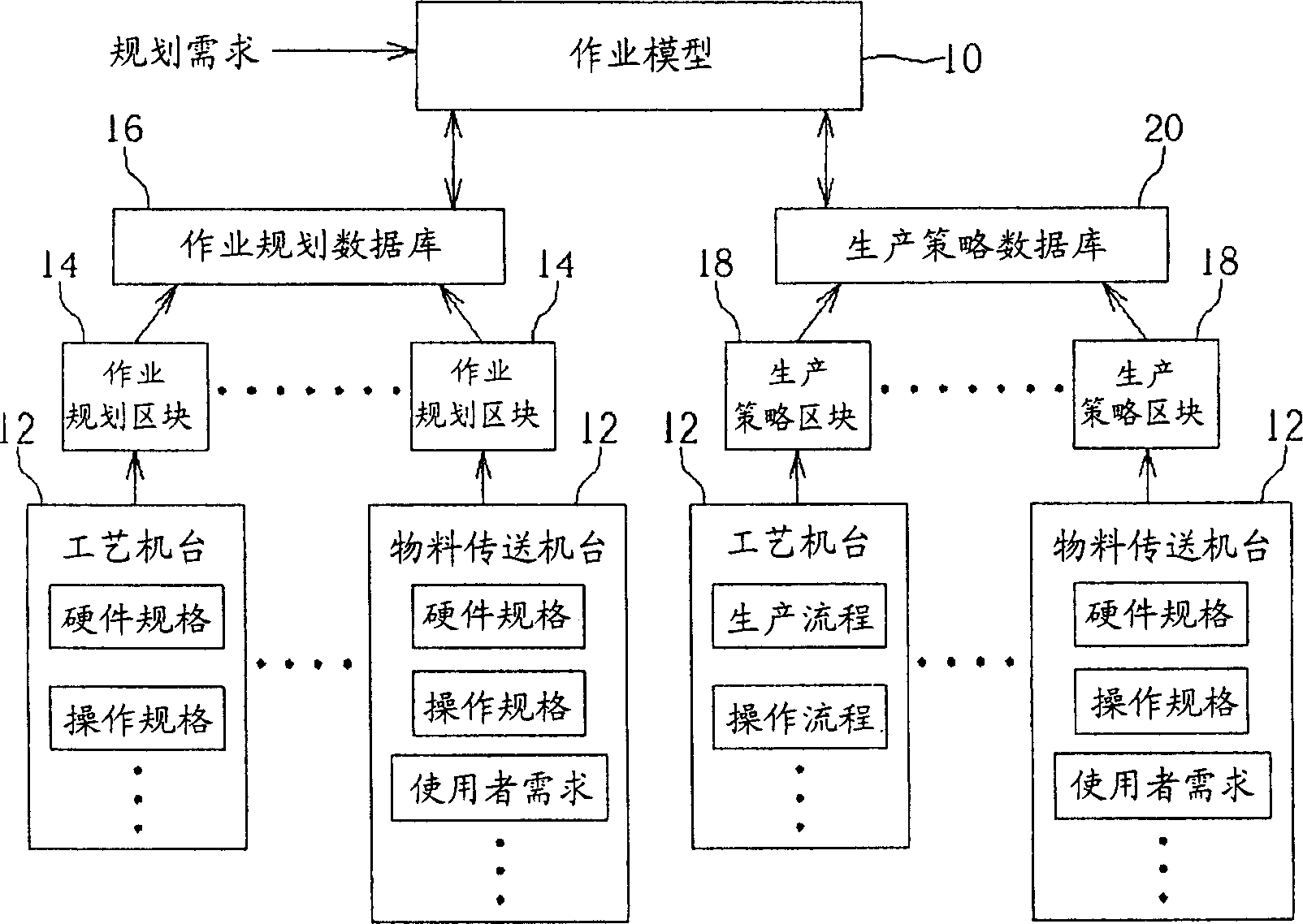

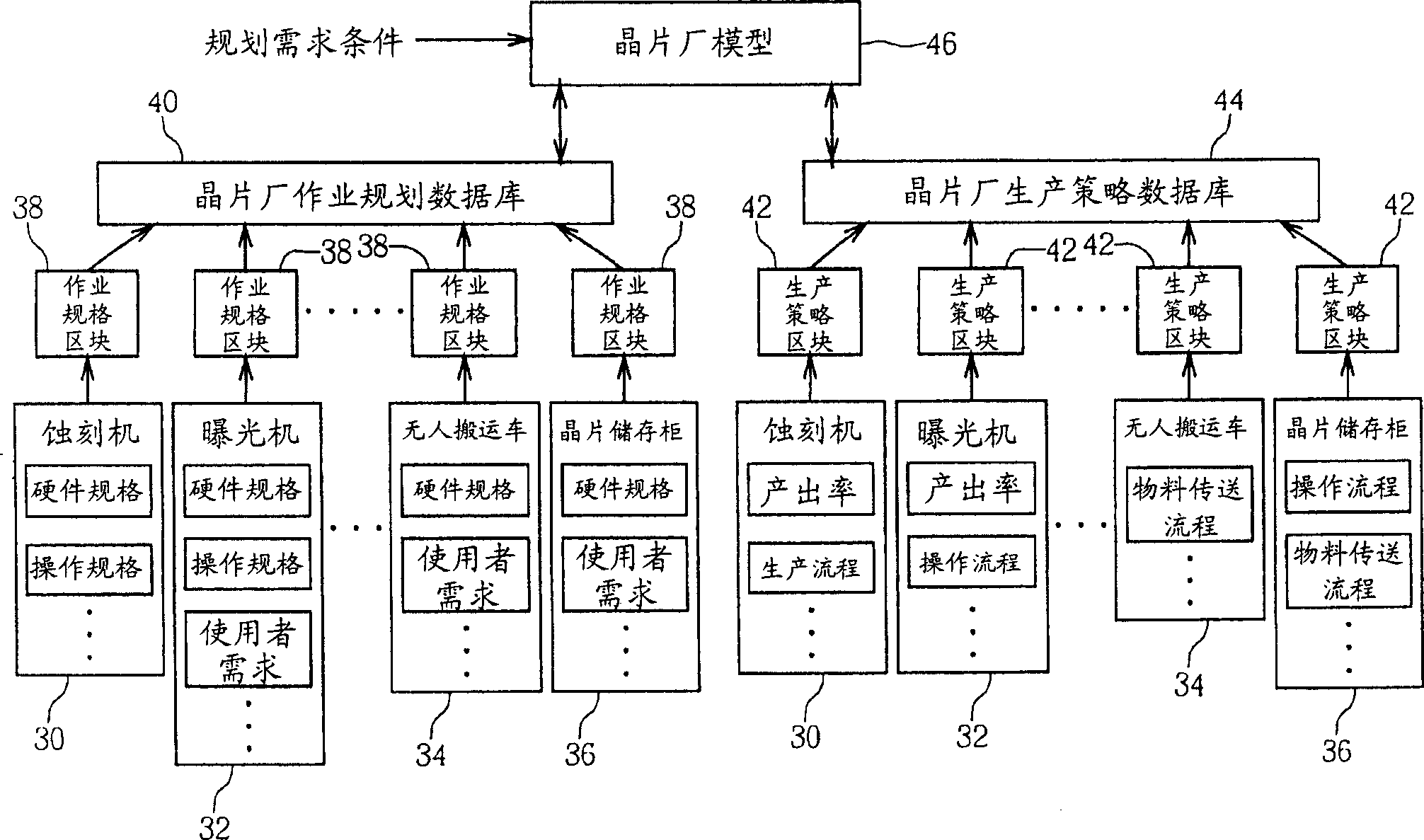

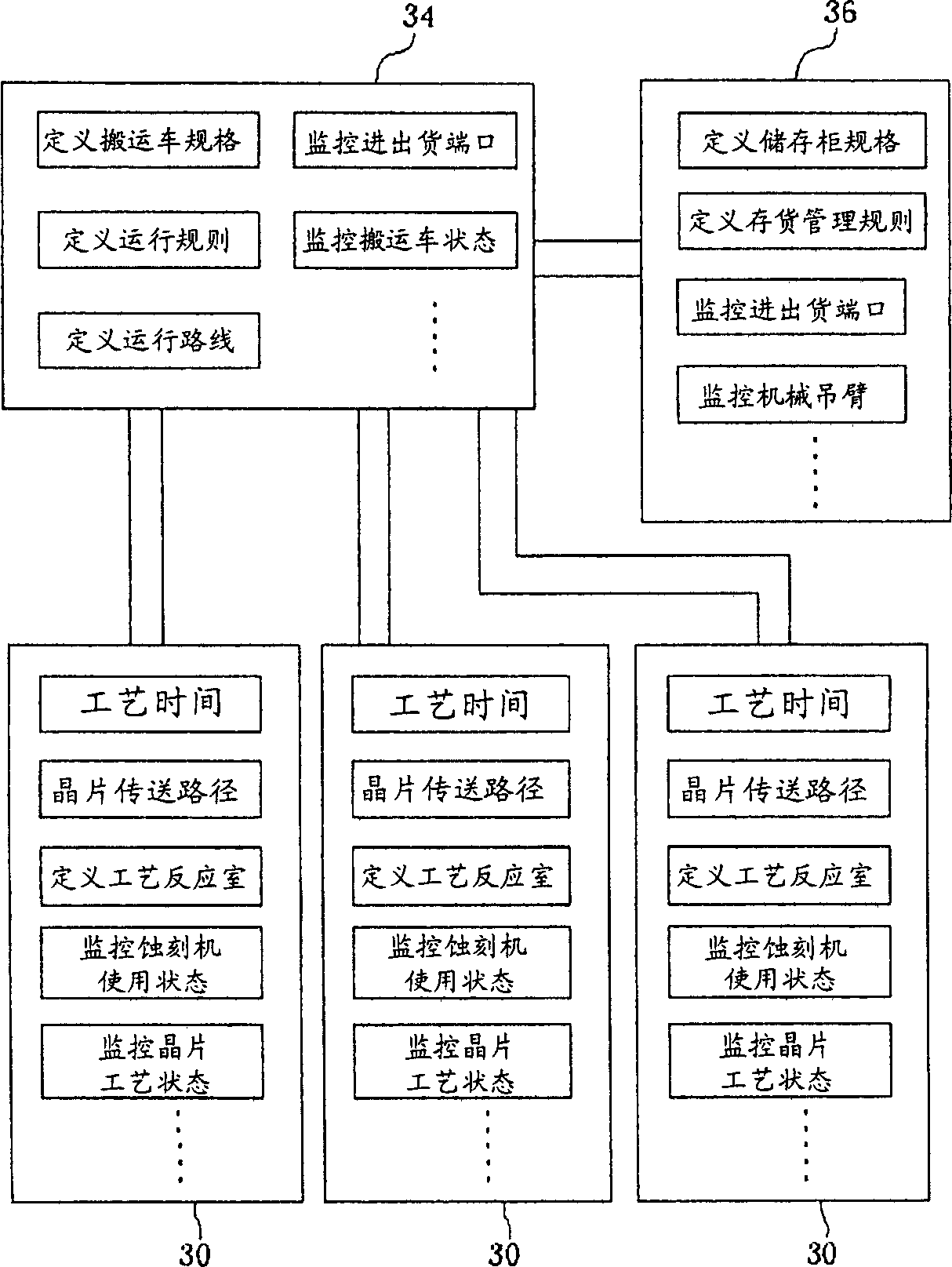

[0022] Please refer to figure 1 , figure 1 It is a schematic flow chart of establishing the operation model 10 of the present invention. Before building a factory, in order to simulate the production process first in order to optimize the production capacity, an operational model (operational model) 10 can be established based on various data and moving line planning strategies. In order to establish this operational model 10, the present invention provides An efficient and flexible simulation method. First, collect various operational data for various production machines 12 to establish an operation planning block (operational block) 14 corresponding to each machine, and then integrate the operation planning blocks of various machines into one operation A planning database (operational library) 16, the operation planning database 16 includes the operation planning block 14 of various manufacturing process machines, material transfer machines and material storage machines. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com