Tool for formed metal plate and section bar

A metal plate and tool technology, applied in the field of forming metal plates and profiles, can solve the problems of increased sensitivity to jaw wear, high machining costs, and complex assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

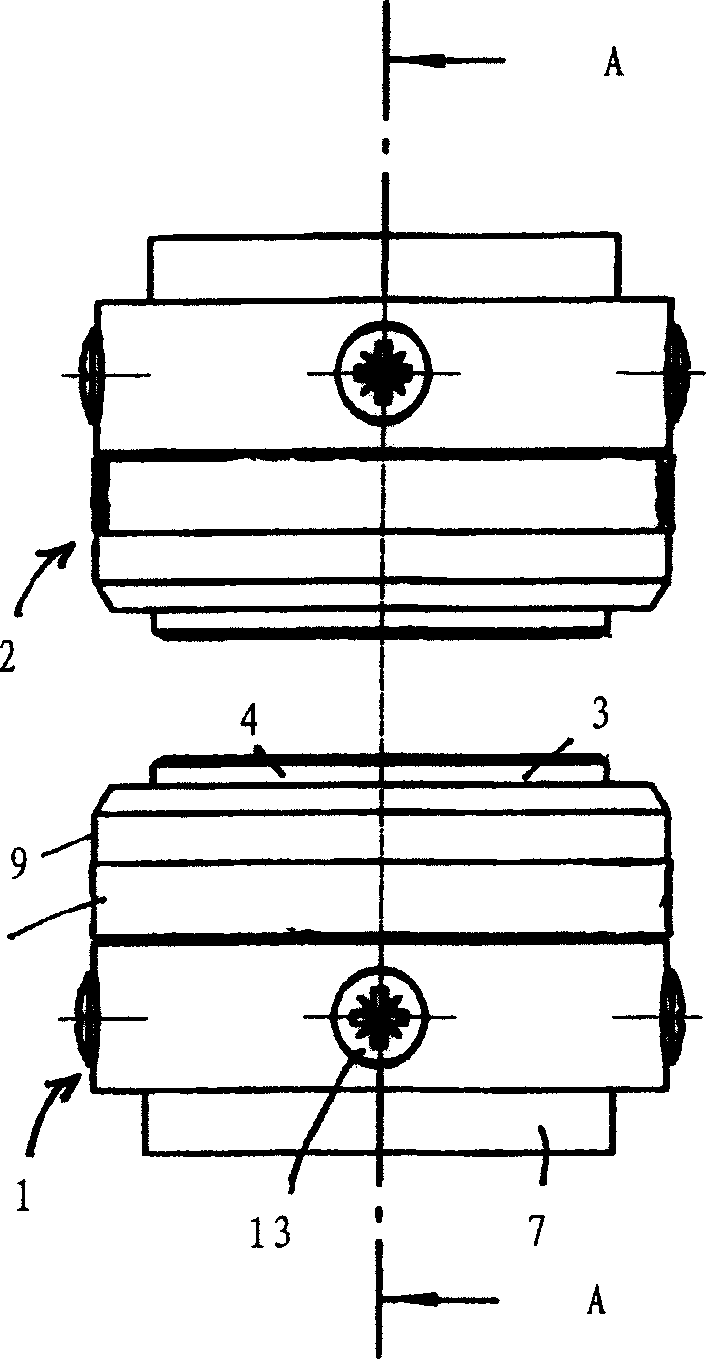

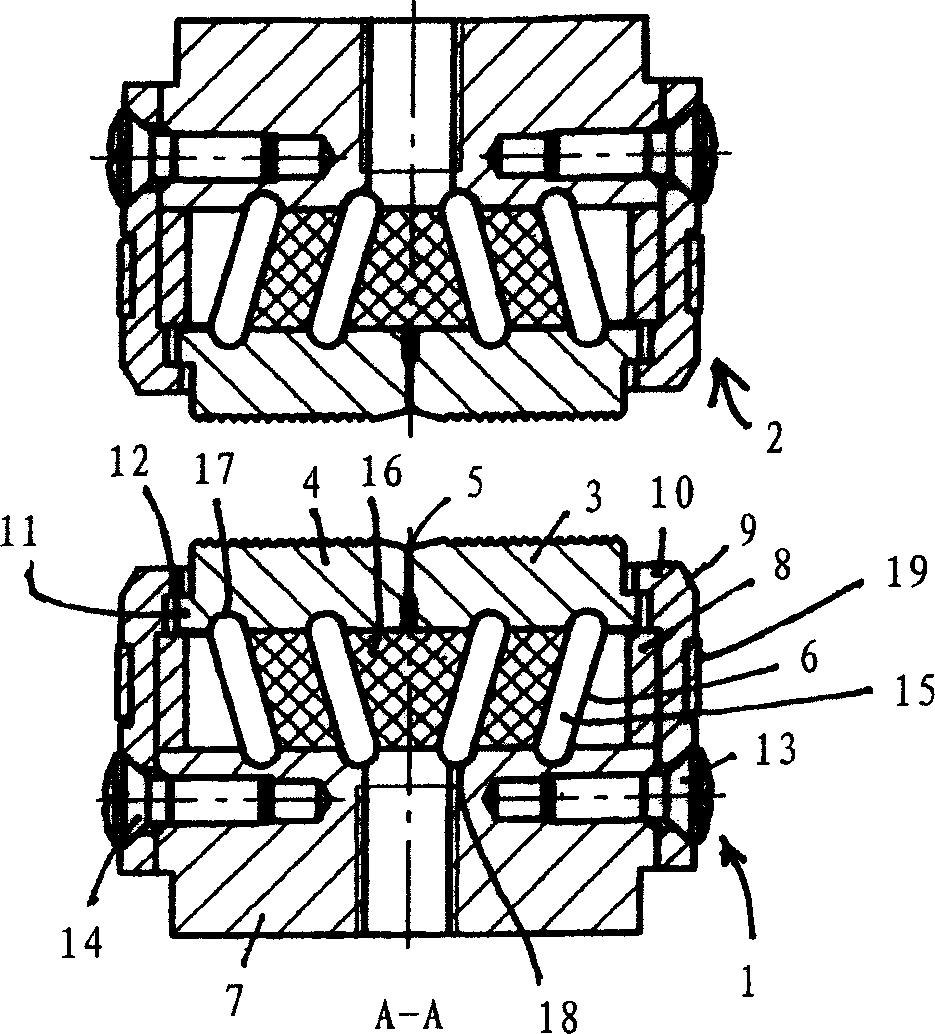

[0012] figure 1 and figure 2 The tool shown comprises a lower tool part 1 and an upper tool part 2 which are of identical construction and which interact to shape the material clamped in place therebetween. In this example, the respective structures of the tool lower part 1 and the tool upper part 2 are as follows.

[0013] A pair of jaws 3, 4 comprises two semi-cylindrical jaws which together form a parting line 5 and are movable in opposite directions for upsetting, spreading or drawing motions . The jaws 3 , 4 are arranged centrally on a deformable support element 6 . This support element 6 is in turn supported on a support element 7 which rests on an actual support base (not shown in the figure). In an edge region, the clamping jaws 3 , 4 rest on an anti-shock ring 8 , which surrounds the support element 6 and is in turn supported on the support element 7 . The individual parts inserted one inside the other and placed one on the other are fixed together by means of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com