Supporting rack

A technology of supporting frame and supporting components, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of poor supporting optical axis transmission pipelines, etc., achieve good fixing effect, and reduce the chance of overlapping pipelines , easy to obtain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

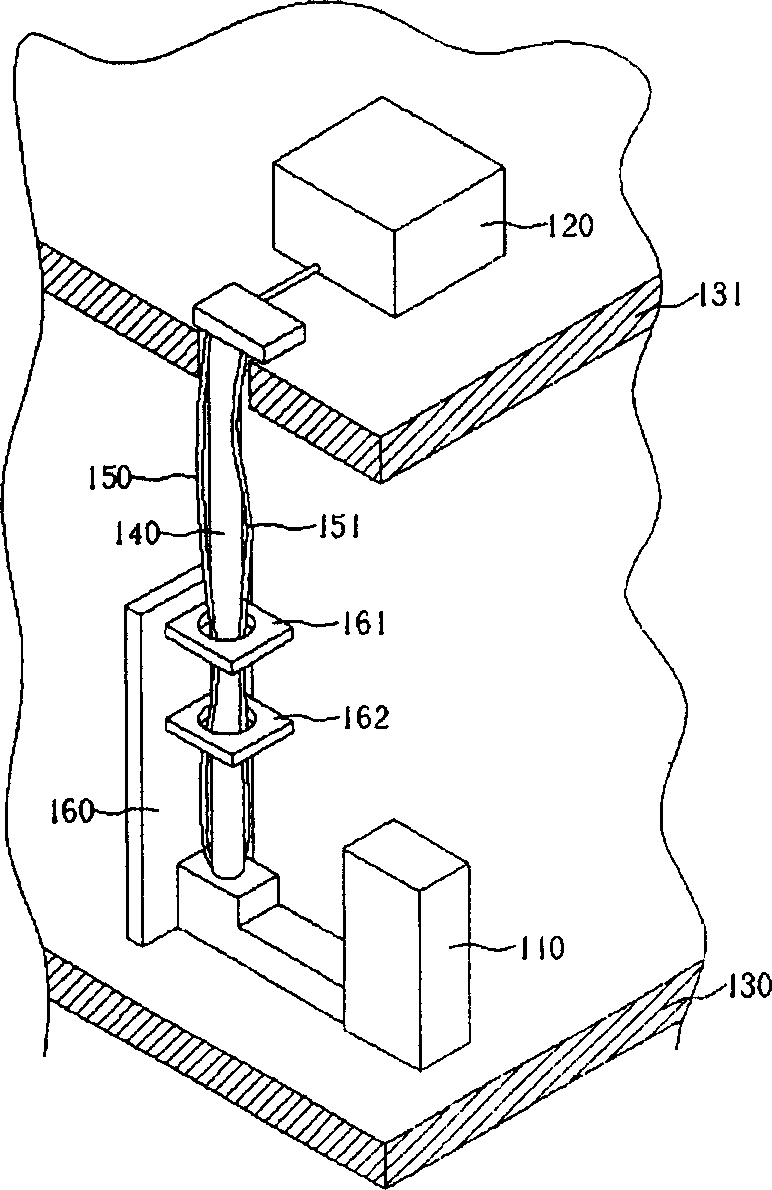

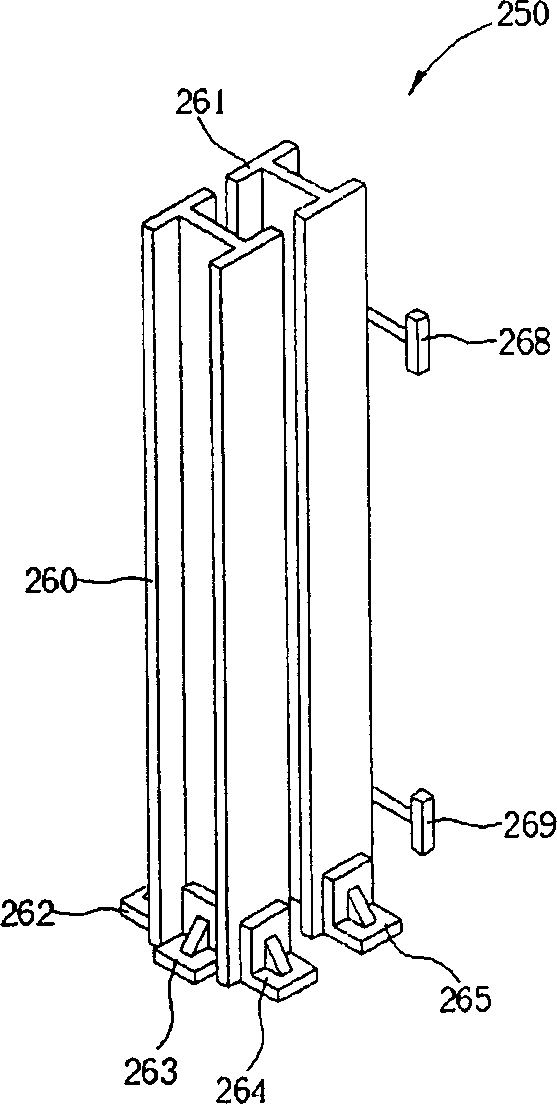

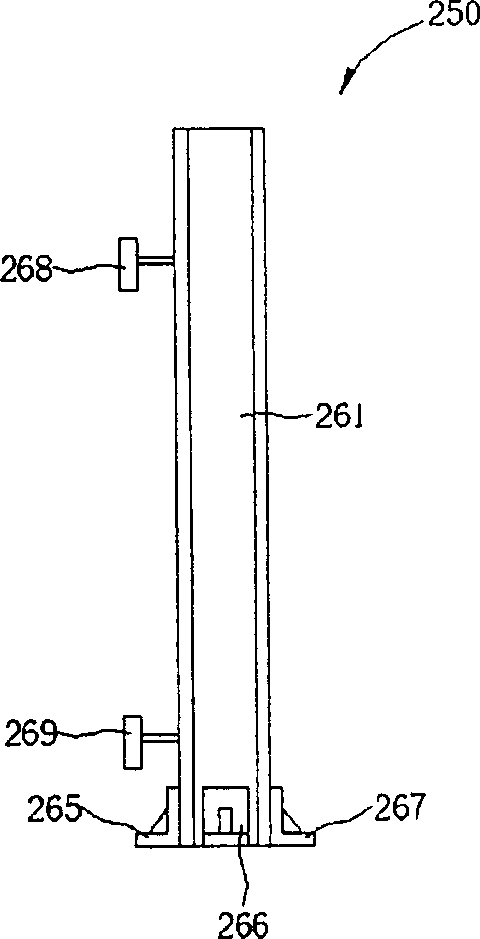

[0016] Please refer to figure 2 , image 3 and Figure 4 , figure 2 is a three-dimensional schematic diagram of the support frame 250 of the present invention, image 3 for figure 2 A side view of the support frame 250 is shown, Figure 4 It is a schematic diagram of the application of the support frame 250 of the present invention. Such as figure 2 with image 3 As shown, the supporting frame 250 includes a plurality of H-shaped steels 260, 261 arranged in parallel and supporting components 262-267, wherein the supporting components 262-267 are used to make the H-shaped steels 260, 261 fixedly engaged with the floor, and support the H-shaped steels 260, 261, for example, if Figure 4 As shown, one end of the plurality of supporting components 262-264 is set on the first part of the H-shaped steel 260, such as the bottom end, and the other end is set on the floor of the floor 230, so that the H-shaped steel 260 and the floor 230 can be fixed well. Engages and effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com