Shadow mask

A shadow mask and slit technology, applied in discharge tubes, electrical components, circuits, etc., can solve the problems of not being able to fall on the cathode ray tube, missing electron beams, and luminance drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

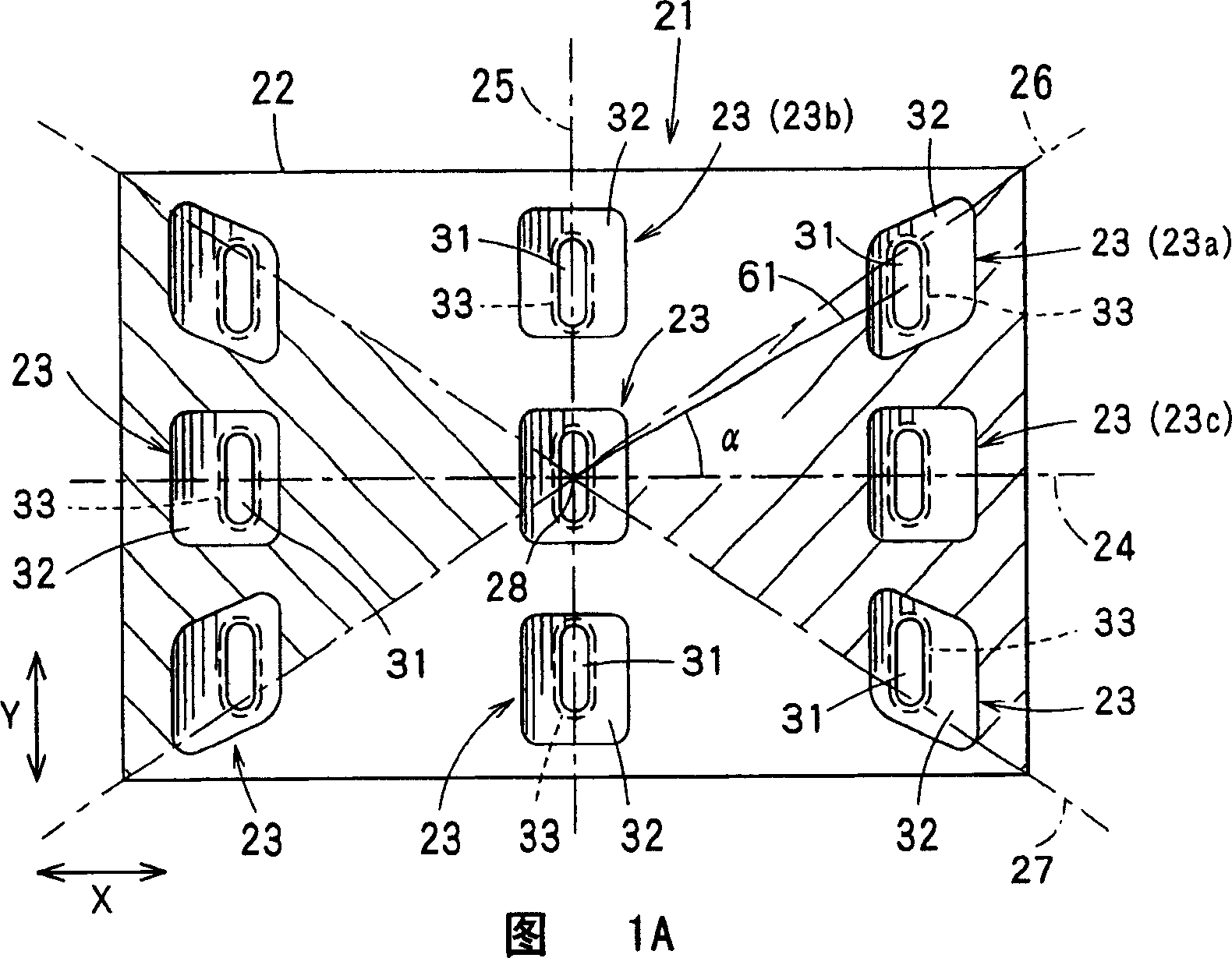

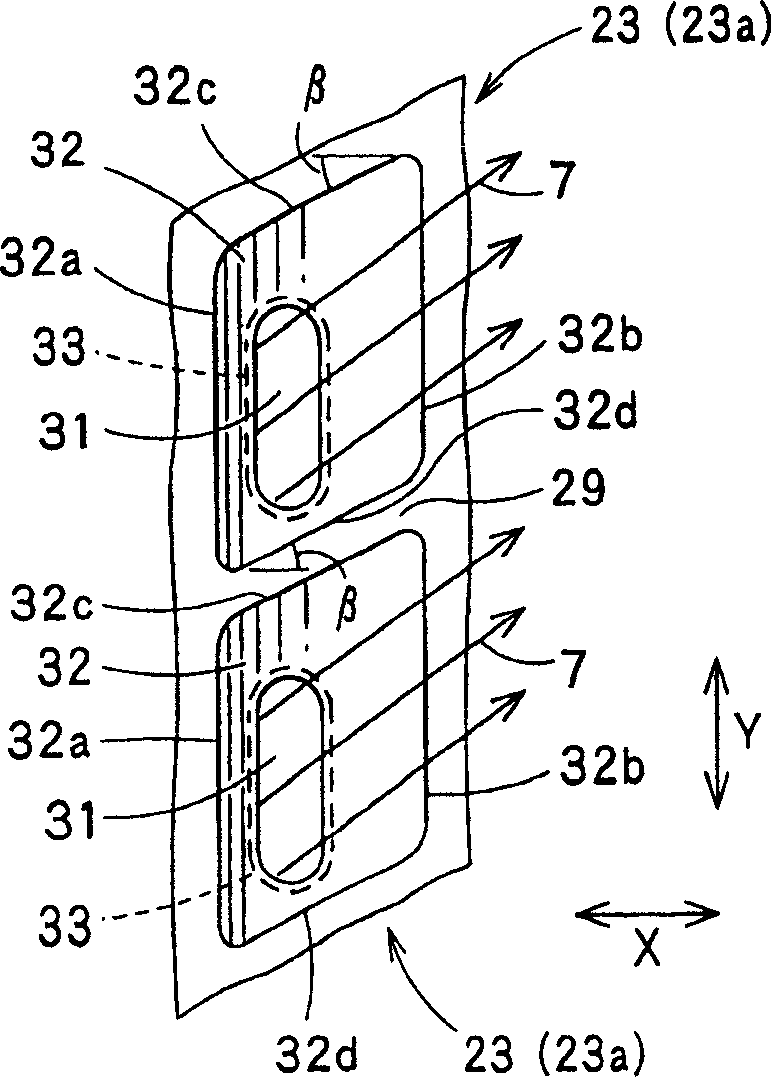

[0033] According to Figure 1A and Figure 1B , the shadow mask according to the first embodiment of the present invention will be described.

[0034] Figure 1A and Figure 1B As shown, the shadow mask 21 of the first embodiment of the present invention has a substantially rectangular shadow mask main body 22, and the shadow mask main body 22 has a plurality of slots 23 (including slots 23a, 23b, 23c), and the slots 23 has a substantially rectangular through hole 31 penetrating in the thickness direction. Here, the through hole 31 of the slit 23 is formed by connecting the front side hole 32 and the back side hole 33 formed by etching a thin metal plate. And, with Figure 4 The solution shown is the same, and a plurality of slots 23 are arranged on the shadow mask main body 22 along the horizontal direction X and the vertical direction Y in plan view. Such a shadow mask 21 is magnetically sealed by being attached to a cathode ray tube, and is used to form a substantially re...

no. 2 Embodiment approach

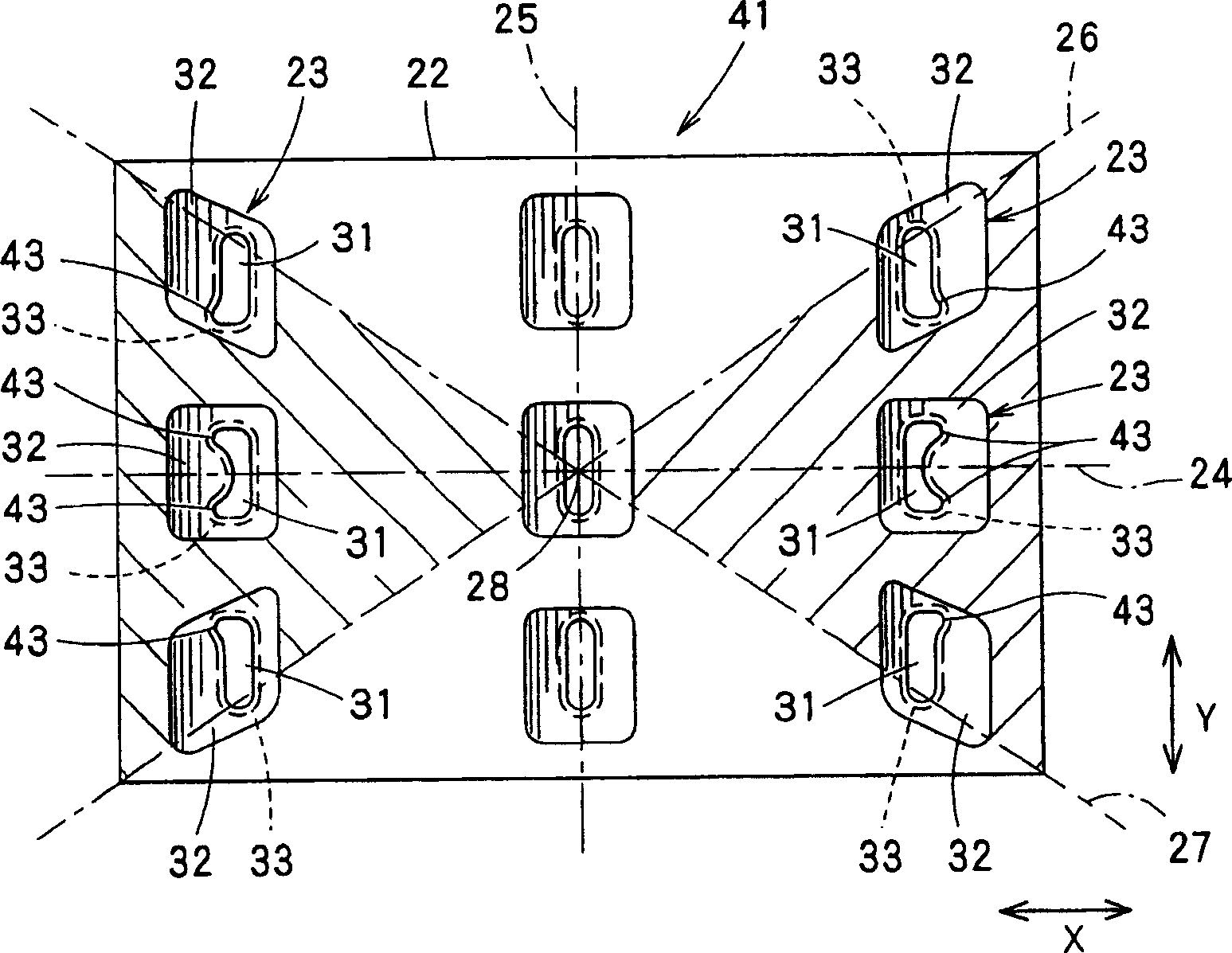

[0051] Next, according to Figure 3A and Figure 3B A shadow mask according to a second embodiment of the present invention will be described. In addition, the second embodiment of the present invention is similar to FIG. 1A and FIG. Figure 1B The first embodiment shown is substantially the same. In Figure 3A and Figure 3B In the second embodiment shown, with respect to Fig. 1A and Figure 1B Components that are the same as in Embodiment 1 shown are denoted by the same reference numerals, and detailed description thereof will be omitted.

[0052] Figure 3A and Figure 3B As shown, the shadow mask 51 of the second embodiment of the present invention has the same Figure 1B The shadow mask 21 shown is similarly constituted, at least in the front side hole portion formed in the area between the horizontal axis 24 and the two diagonal axes 26, 27 of the shadow mask main body 22 (the shaded portion in FIG. 3A ). 32, only the side 32c on the side of the non-horizontal axis 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com