Printing material sheet gripper

A printing material and gripper technology, which is applied to the gripper system, the machine for processing sheet-fed printing materials, and the field of manufacturing sheet-fed grippers, which can solve the problems of not making real effective contributions and achieve the service life. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

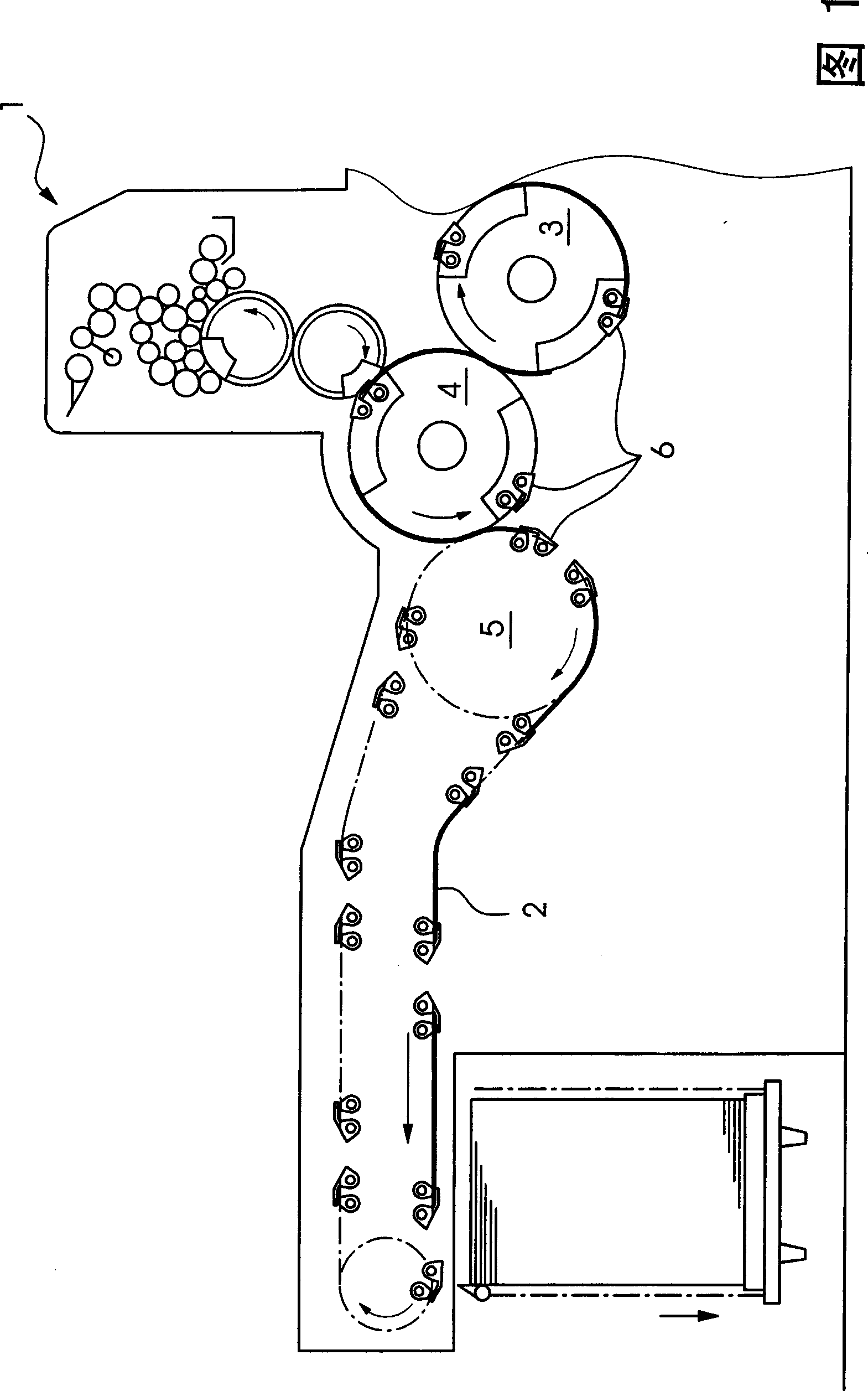

[0028] figure 1 A machine 1 for processing sheet-fed printing materials 2 is shown. The machine 1 is a rotary printing press for lithographic offset printing and comprises sheet-fed transport devices, which are a transfer cylinder 3 , an impression cylinder 4 and a chain conveyor 5 . These sheet-sheet transport devices each comprise a bridge-shaped gripper system 6 .

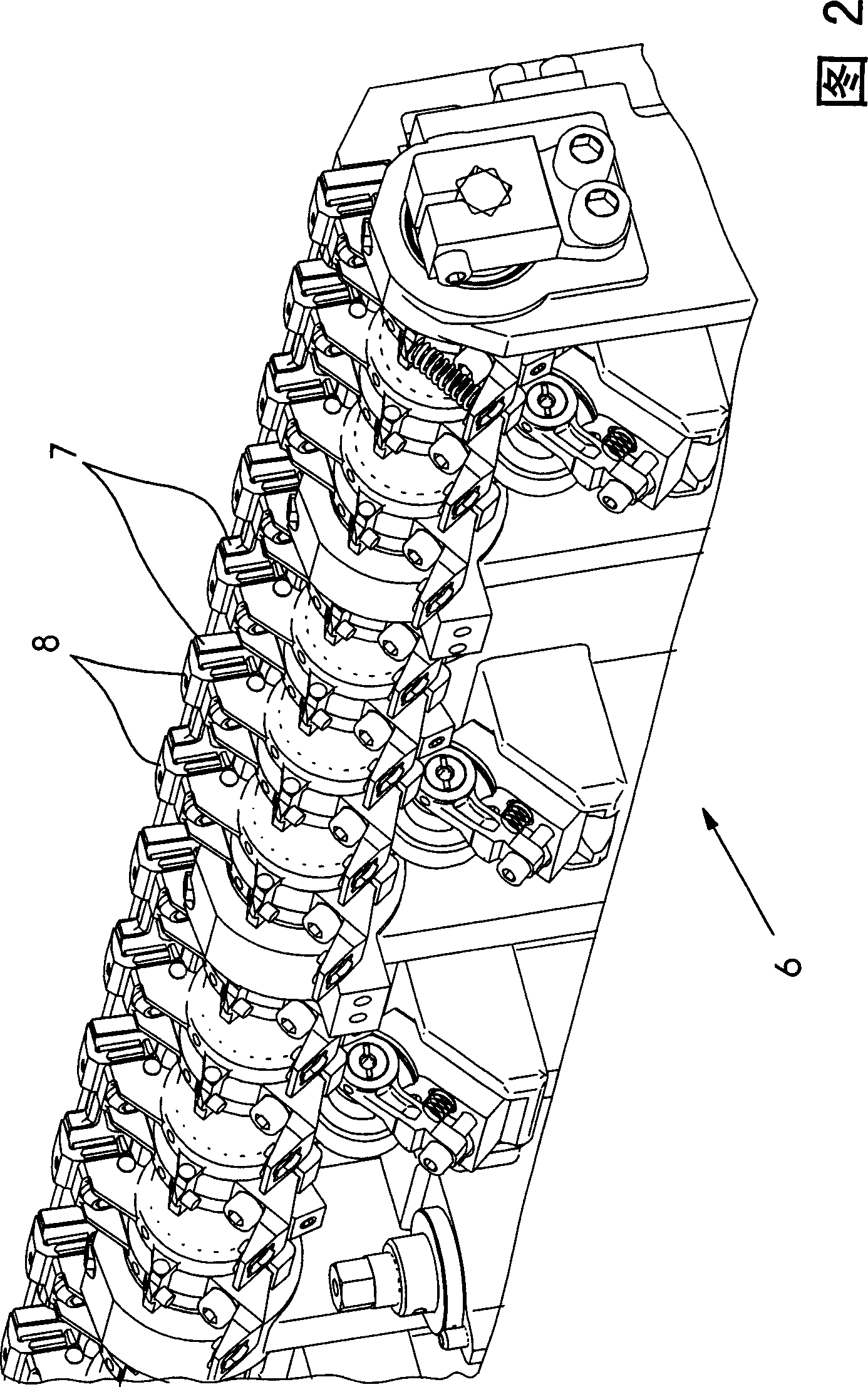

[0029] figure 2 Representation: Each gripper system 6 comprises a gripper holder 7 and a single-sheet gripper 8 pivotable relative to the gripper holder, which are arranged in a row. The gripper system 6 is used to grip the leading edge of the current sheet-fed printing material 2 .

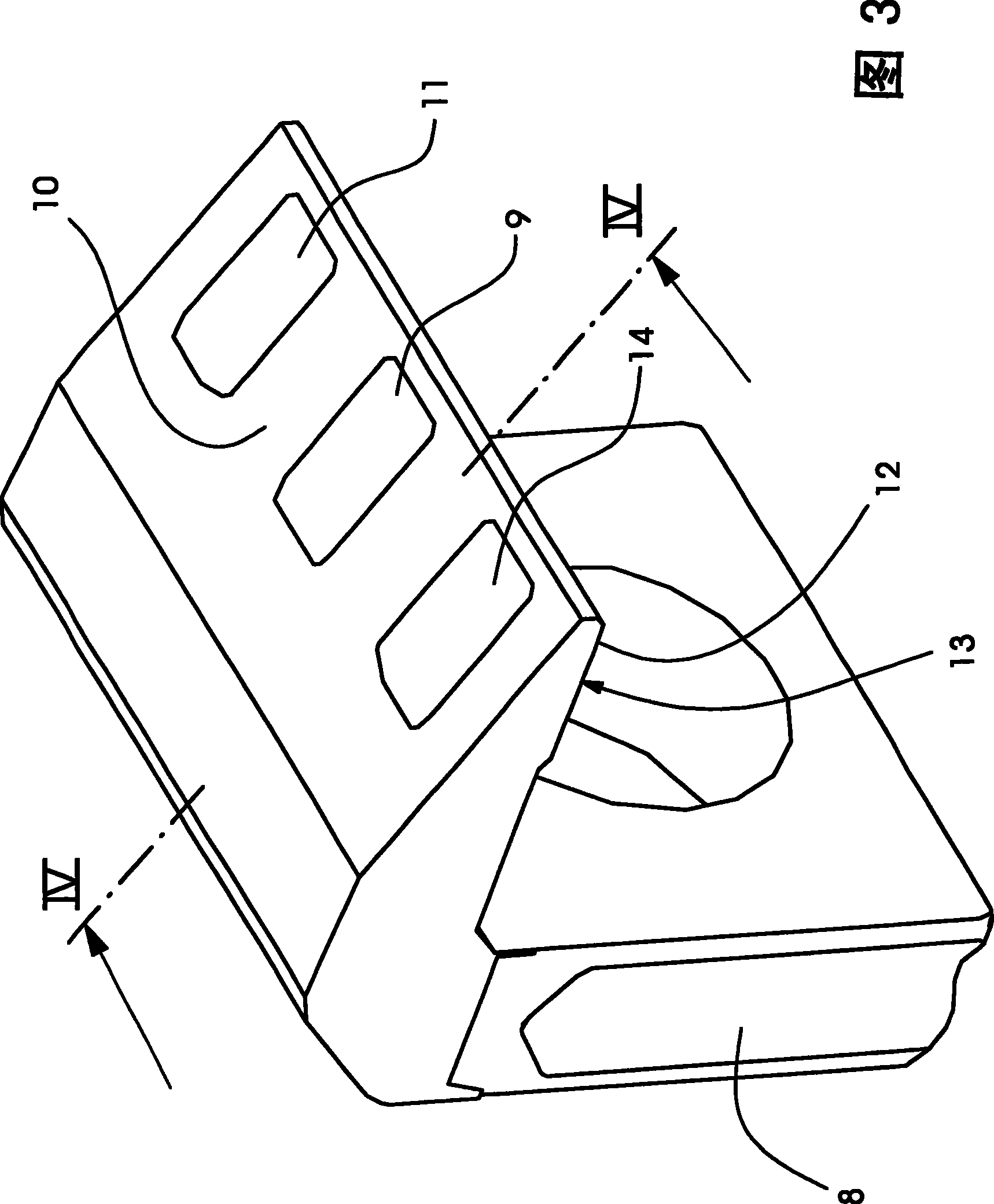

[0030] image 3 Representation: Each sheet-fed gripper 8 has a gripper core 9 and a shell 10 covering the gripper core 9 .

[0031] Gripper core 9 is made of a metal as base material 11 . The housing 10 consists of a clamping surface material 12 , that is to say the material which forms the clamping surface 13 of the sheet-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com