Production method of wood face plate of steel and wood door

A production method and technology for steel and wood doors, applied in the direction of manufacturing tools, wood processing appliances, etc., can solve the problems of cracks in the paint surface at the splicing, large color contrast, affecting the surface appearance of the door leaf, etc., and achieve the effect of scientific production technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

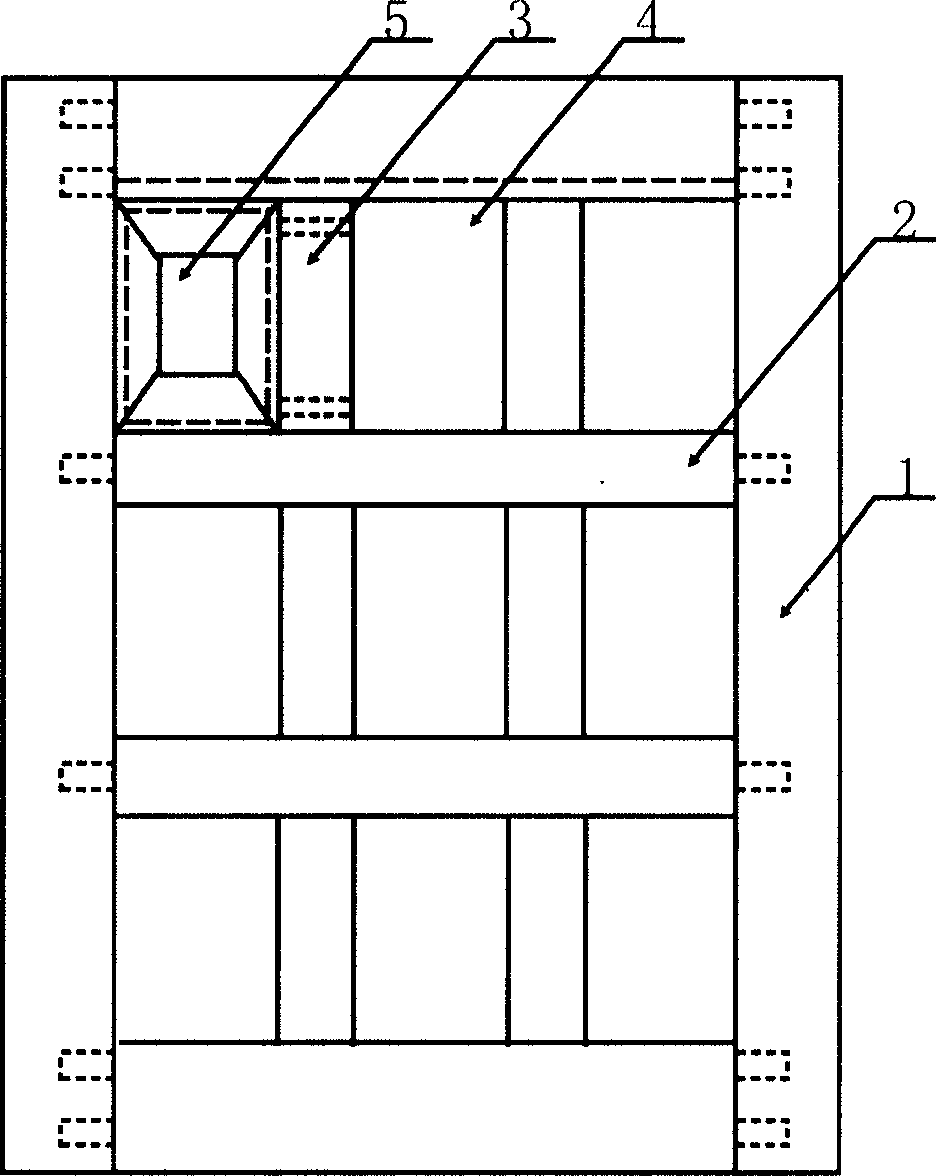

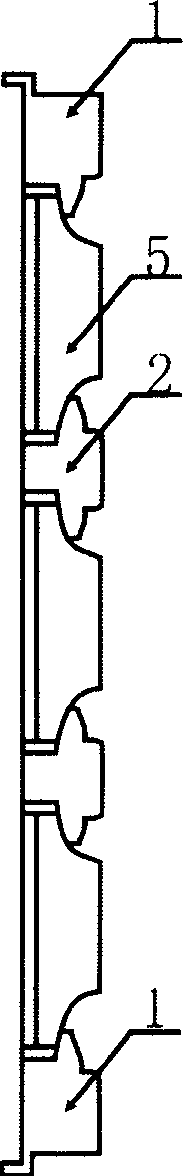

[0017] Embodiment 1: as figure 1 , figure 2 , image 3 Shown, a kind of manufacture method of steel wood door solid wood panel, it comprises the following steps:

[0018] Prepare the frame: the frame includes vertical bars and horizontal bars, the vertical bars and horizontal bars are connected by mortise and tenon to form the outer frame 1, and horizontal bars are set between the left and right outer frames, and they are connected with the mortise on the outer frame by tenon to form In the middle beam 2, a vertical beam 3 is set between the outer frame and the middle beam, and the edges of the middle beam 2 and the vertical beam 3 are provided with cooperating tenons or grooves, forming several square frames 4, each square frame 4 The inner sides are provided with mortise and grooves all around, and then painted, primer first, then sanded, then painted, and finally modified; when preparing the frame, the outer frame 1 is made, the outer frame 1 is connected with the middle...

Embodiment 2

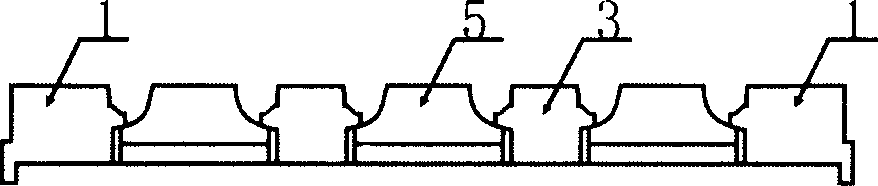

[0021] Embodiment 2: as Figure 4 Shown, a kind of manufacture method of steel wood door solid wood panel, it comprises the following steps:

[0022] Prepare the frame: the frame includes vertical bars and horizontal bars, the vertical bars and horizontal bars are connected by mortise and tenon to form the outer frame 1, vertical bars are set between the upper and lower outer frames, and they are connected by mortise and tenon on the outer frame to form In the middle beam 2, a vertical beam 3 is set between the outer frame and the middle beam, and the edges of the middle beam 2 and the vertical beam 3 are provided with cooperating tenons or grooves, forming several square frames 4, each square frame 4 Mortises and grooves are set on all sides of the inside, and then primed first, then polished, then painted, and finally modified; when preparing the frame, the outer frame 1 is made, the outer frame 1 is connected with the middle beam 2, and the mortises and tenons need to be gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com