Preparation method of large diameter zone melting silicon single crystal

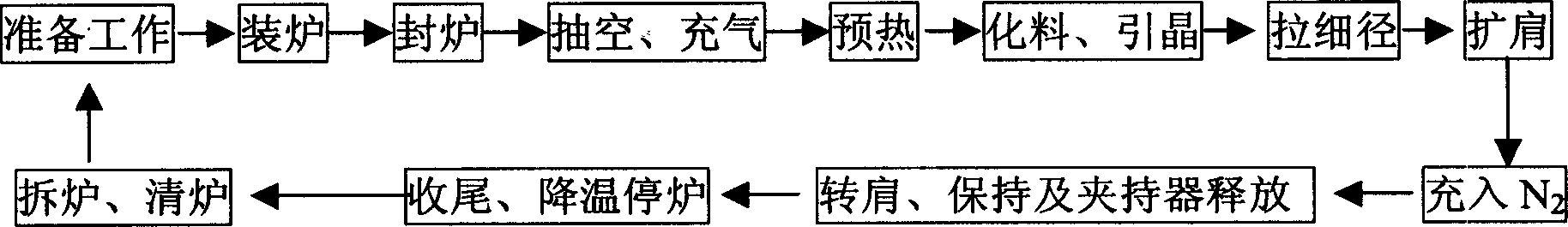

A zone melting single crystal furnace and zone melting silicon technology are applied in the field of large-diameter zone melting silicon single crystal preparation, and can solve problems such as being unable to be successfully realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The production of large-diameter zone-melting silicon single crystals, especially Φ≥4 "zone-melting silicon single crystals, is a test for both the crystal pulling process and the crystal pulling equipment. The zone melting single crystal furnace disclosed in the present invention is produced by the Danish Trust The model is FZ-30 produced by Pusuo Company. During the crystal pulling process, it is necessary to constantly adjust the set point of the generator of the zone melting single crystal furnace, and the set point of the anode voltage of the generator of this equipment is given in percentage. That is, every time the power is adjusted, the percentage will always be displayed on the touch screen. For example, when the diameter of the zone-melted silicon single crystal expands to Φ110mm-130mm, the anode voltage setting point at this time is generally 70%. If the anode voltage is increased by 0.1% , then the set point displayed on the touch screen should be 70.1%.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com