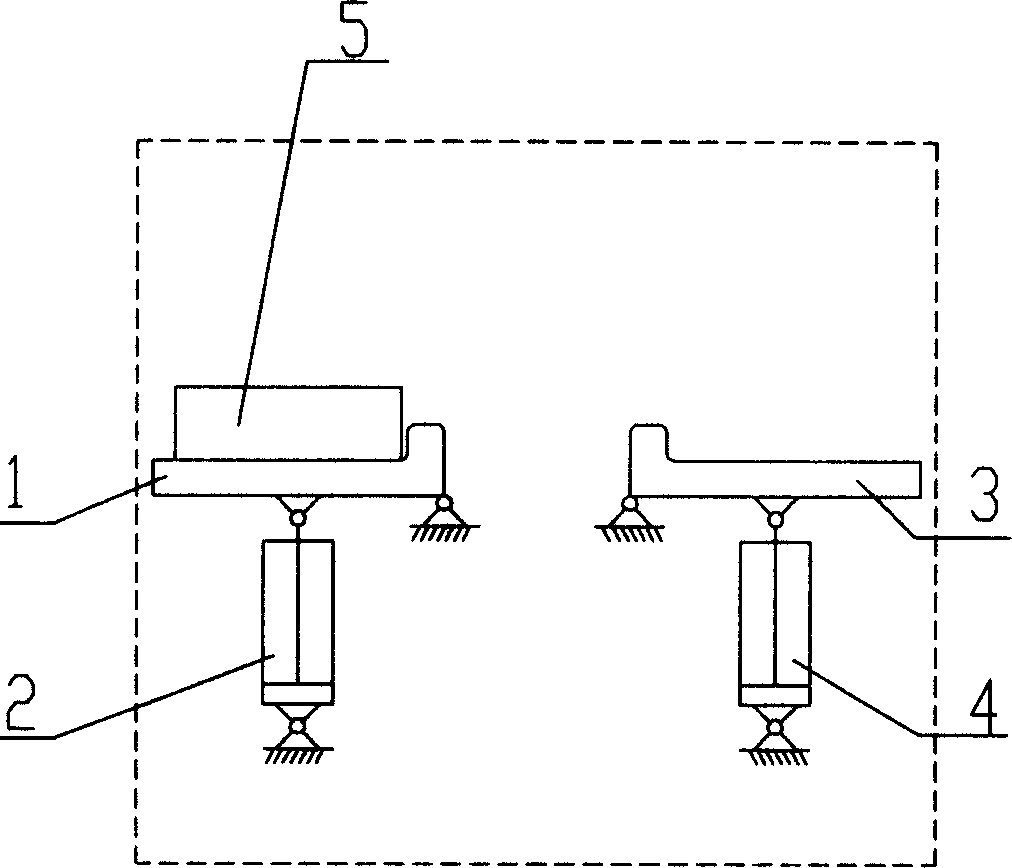

Compound controlling hydraulic system of blank turnover machine

A composite control and hydraulic system technology, applied in the field of hydraulic system equipment, can solve the problems of large reversing impact, high operating cost and low service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

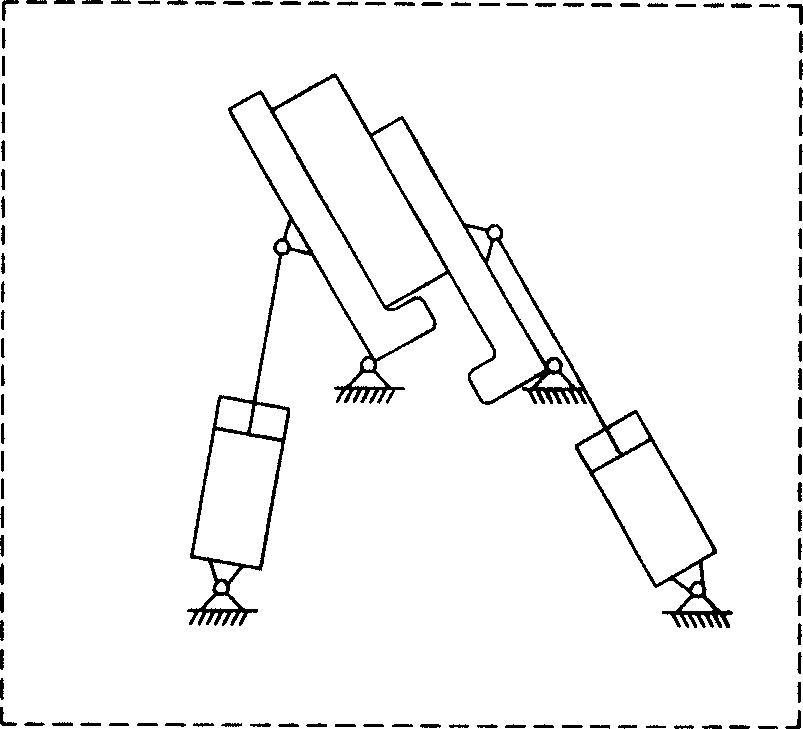

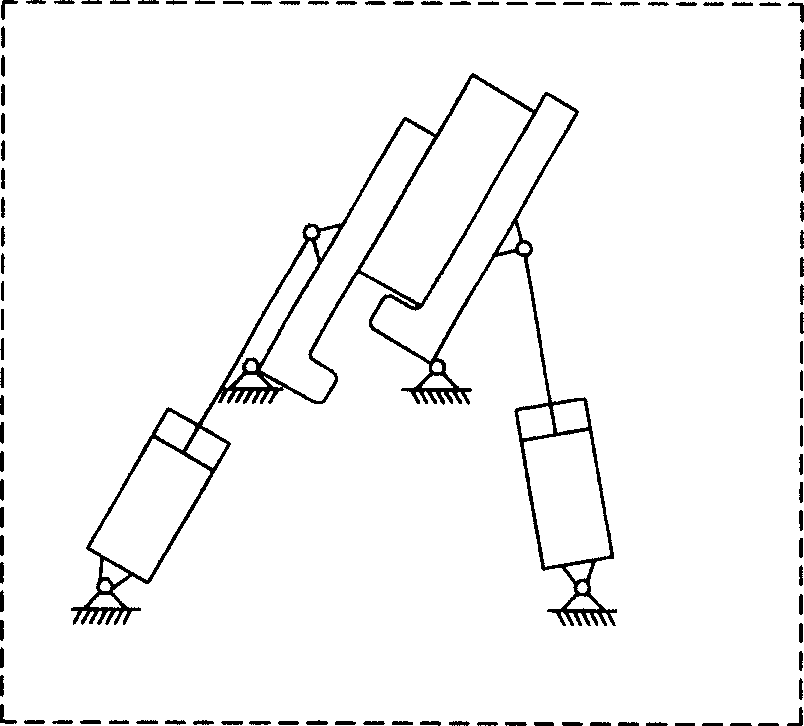

[0013] Example Figure 5 As shown, the pressure oil end of each of the four drive cylinders 2 connected to the left arms L of the blank turning machine is respectively connected to a speed regulating device, and the speed regulating device is composed of a speed regulating valve The rectifying plates 4-1~4-4 form a bridge structure with the speed control valves 3-1~3-4 respectively, so that the piston rods of the four hydraulic cylinders are extended and retracted, and the piston rods of the four hydraulic cylinders are extended and retracted synchronously. The speed regulating valve 3-1~3-4 is controlled; the input control end of the speed regulating device and the left arm L are composed of the speed regulating valve rectifying plate 4-1~4-4 and the speed regulating valve 3-1~3-4 respectively. The output end of the first balance valve 2-1 controlled by the oil circuit is connected, and the input end of the 2-1 balance valve is connected to the A end of the proportional elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com