Drying system of film developing machine

A drying system, processor technology, applied in drying/glazing processing materials, etc., can solve problems such as loss, fire, damage to film parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

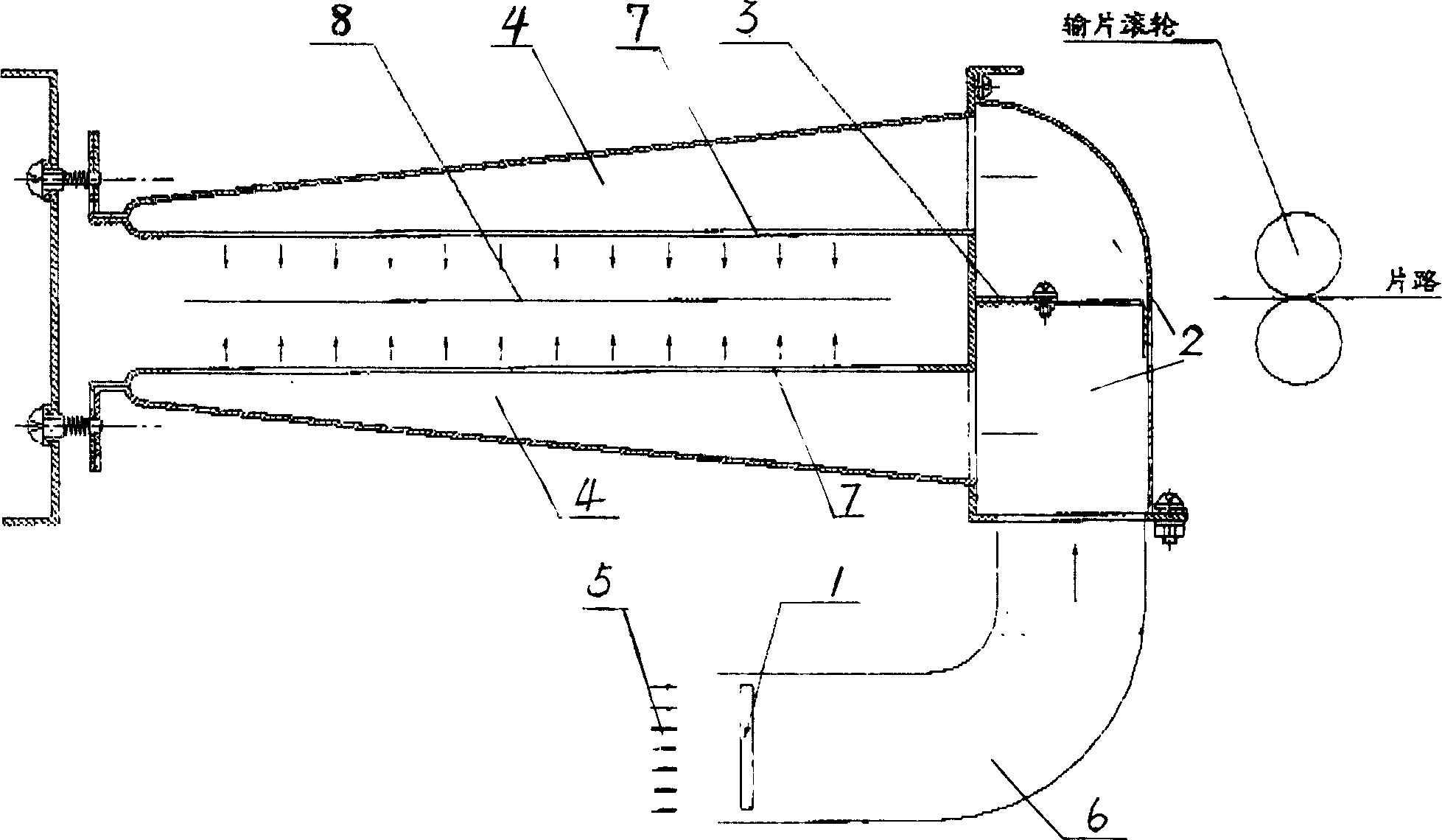

[0009] by figure 1 It is the best embodiment of the present invention.

[0010] The main components of the film processor drying system are fan 5, PTC drying ceramic heating element 1, air duct 6, hot air box 2, air volume adjustment plate 3, and tapered air duct 4. The PTC dry ceramic heating element 1 is installed in an appropriate position of the air duct 6, and the air duct 6 is sealed and connected with the hot air box 2. The hot air box 2 is divided into upper and lower parts of the box, and the air volume regulating plate 3 in the hot air box 2 can adjust the air volume of the upper and lower boxes of the hot air box, so that the air volume of the upper and lower box air outlets of the hot air box 2 is even. The large openings of the upper and lower tapered air ducts 4 are respectively connected to the upper and lower hot air box 2 air outlets, and the other end is fixed on the wallboard. When the fan 5 works, the wind blows to the PCT ceramic heating element 1, causi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com