Nano silver shell/single dispersion SiO2 composite particle materia land its producing method and use

A technology of nano-silica and composite particles, which is used in the agglomeration of nano-powders formed by composite particles, composite particle materials of nano-metal shell/silica core and their preparation fields, which can solve the problem of uncontrollable coating thickness, etc. problems, to achieve the effect of low cost, high product purity and low emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

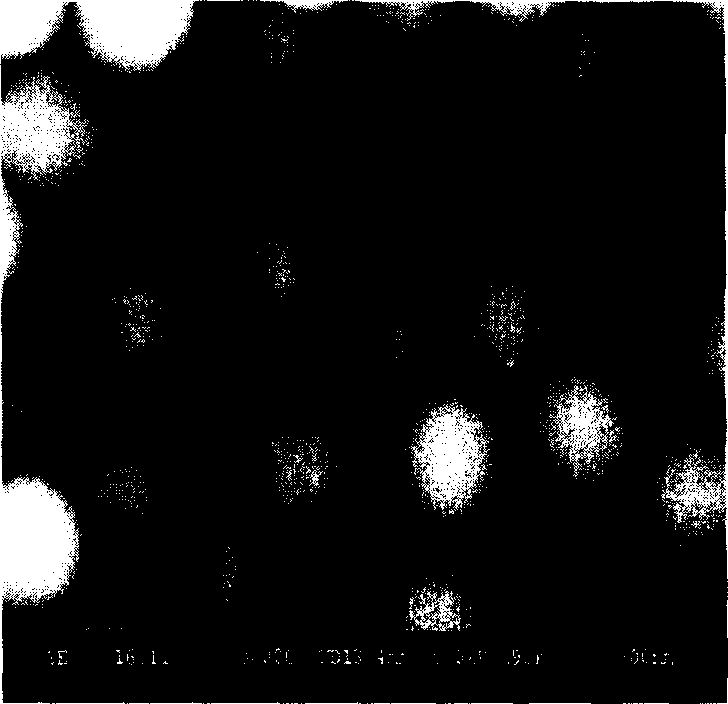

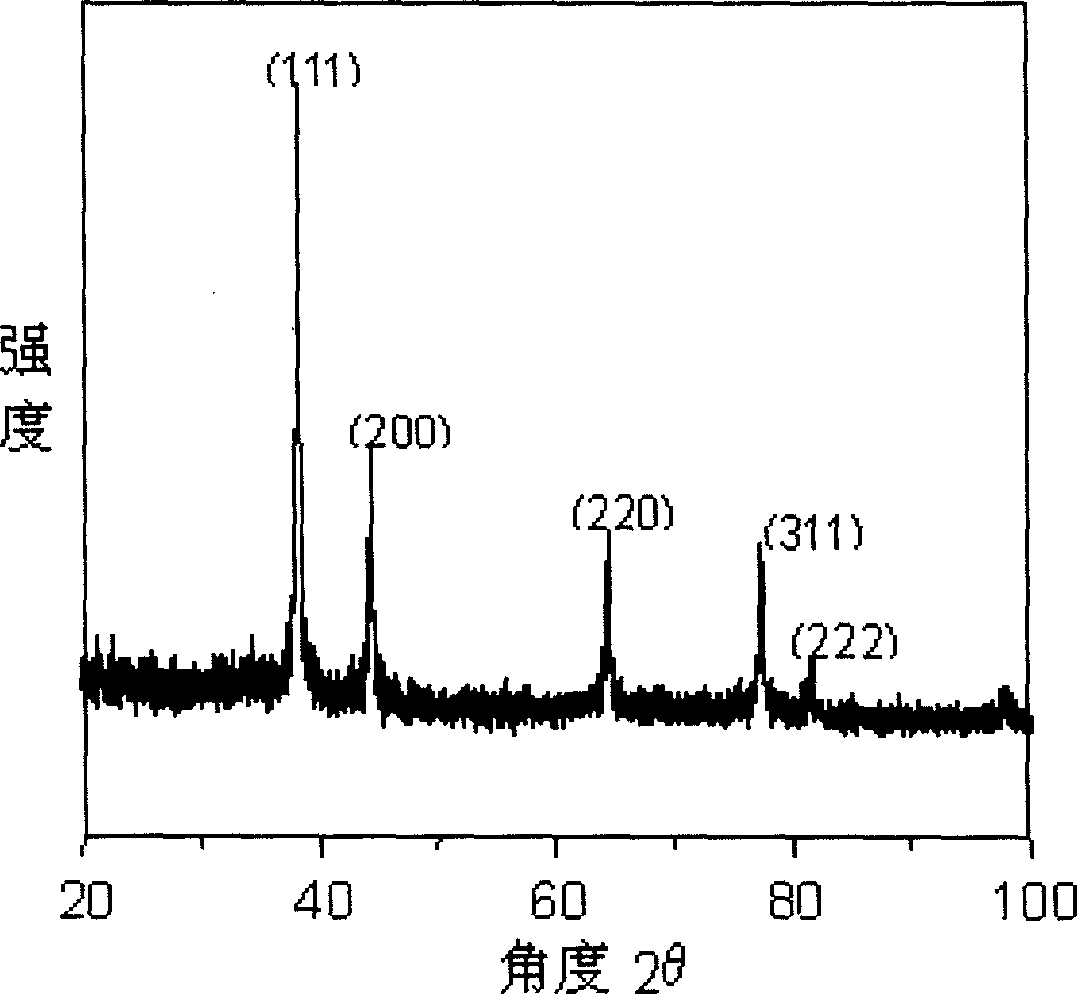

Embodiment 1

[0027] (1) 3.5 grams of 250 nanometer monodispersed silicon dioxide particles are mixed with 4.0 grams of silver oxide and placed in a planetary grinder, and ground for several hours;

[0028] (2) The ground mixture is heated in an electric furnace at a temperature of 340°C, and after being kept for one day, it is cooled to room temperature;

[0029] (3) Place the product in an autoclave, add high-viscosity, high-boiling point inert liquid solvent paraffin oil and an electromagnetic stirrer, the weight percent concentration of the suspension is 0.1%, seal; heat and stir at 130 ° C, remain for hours or days;

[0030] (4) Centrifugal separation, wash and separate repeatedly with ethanol solvent, after drying, obtain the wavelength-regulating particles of the yellow surface plasmon material of the silver nanocrystal composite assembly on the spherical nano-silicon dioxide particle surface, and the layer thickness is about 14 to 19 nm.

Embodiment 2

[0032] (1) 5.25 grams of 250 nanometer monodispersed silicon dioxide particles are mixed with 4.0 grams of silver oxide and placed in a planetary grinder, and ground for several hours;

[0033] (2) The ground mixture is heated in an electric furnace at a temperature of 360°C, and after being kept for one day, it is cooled to room temperature;

[0034] (3) Place the product in an autoclave, add high-viscosity, high-boiling point inert liquid solvent paraffin oil and an electromagnetic stirrer, the weight percent concentration of the suspension is 0.01%, seal; heat and stir at 120 ° C, remain for hours or days;

[0035] (4) Centrifugal separation, wash and separate repeatedly with ethanol solvent, after drying, obtain the wavelength adjustment particles of the light yellow surface plasmon material assembled on the surface of spherical nano silicon dioxide particles by silver nanocrystal composite, with a layer thickness of about 60 to 85 nm.

Embodiment 3

[0037] (1) 3.5 grams of 400 nanometer silicon dioxide particles are mixed with 4.0 grams of silver oxide and placed in a planetary grinder, and ground for several hours;

[0038] (2) The ground mixture is heated in an electric furnace at a temperature of 380°C, kept warm for several hours to several days, and then cooled to room temperature;

[0039] (3) The resultant is placed in an autoclave, and a high-viscosity, high-boiling point inert liquid solvent glycerin and an electromagnetic stirrer are added, and the concentration by weight of the suspension is 3%, sealed; heated and stirred at 120° C., kept hours or days;

[0040] (4) Centrifugal separation, repeated washing and separation with ethanol solvent, after drying, obtain the wavelength adjustment particles of the light yellow surface plasmon material of the silver nanocrystal composite assembly on the surface of the spherical nano-silicon dioxide particles, and the thickness of the layer is about 12 to 16 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com