Automatic marking production line of bearing

A production line and bearing technology, applied in printing, rotary printing machines, printing machines, etc., can solve problems such as unstable marking pressure, difficult to guarantee marking quality, and inaccurate marking positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

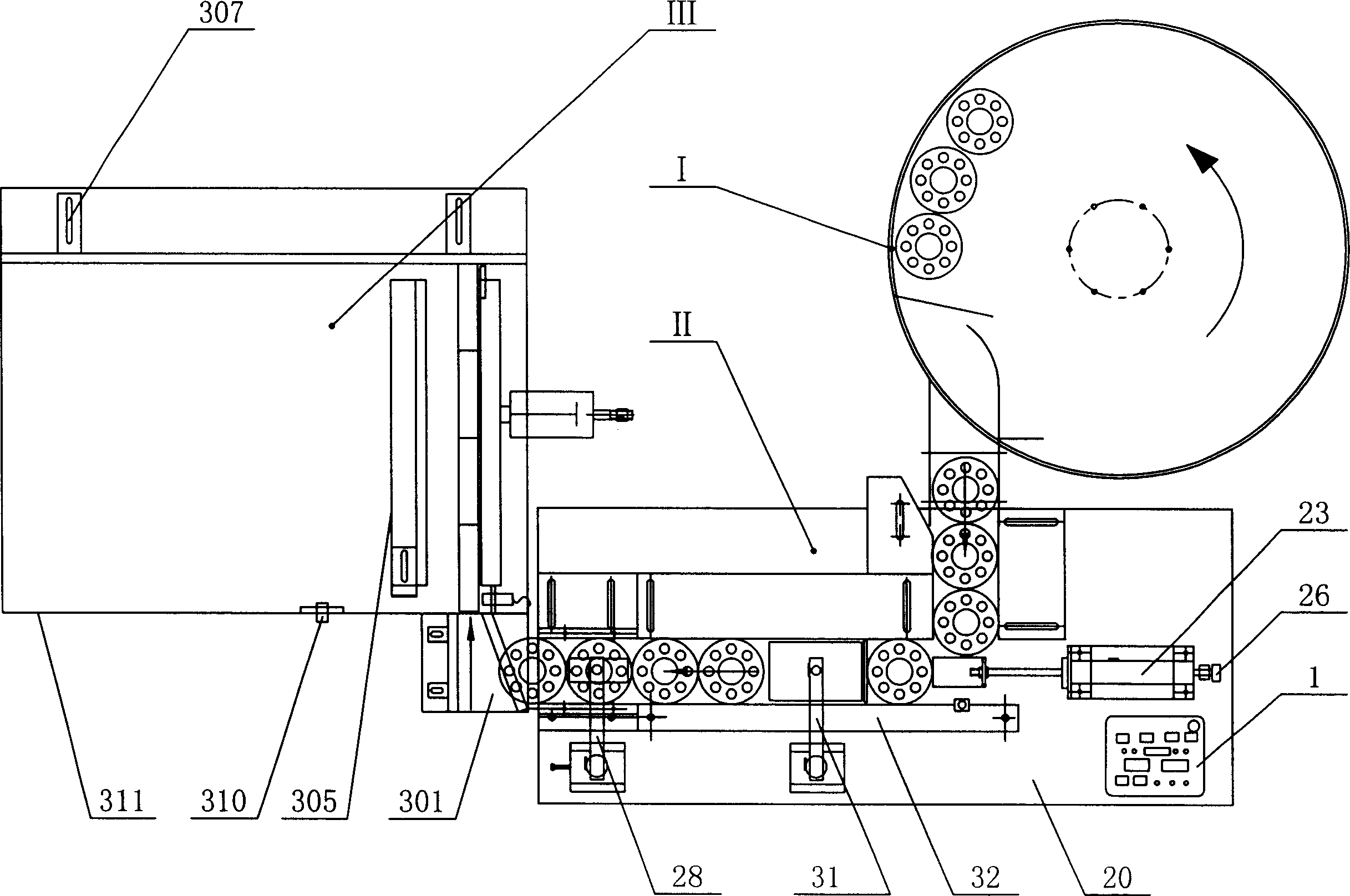

[0066] Such as figure 1 As shown, the automatic bearing marking production line of the present invention is characterized in that it is composed of an automatic feeder I, an automatic marking host II, and an automatic receiving machine III. The discharge port of the automatic feeder I and the automatic marking host II enter The feed port is connected, and the discharge port of the automatic marking host II is connected with the bearing inlet of the automatic receiving machine III, and is electrically connected.

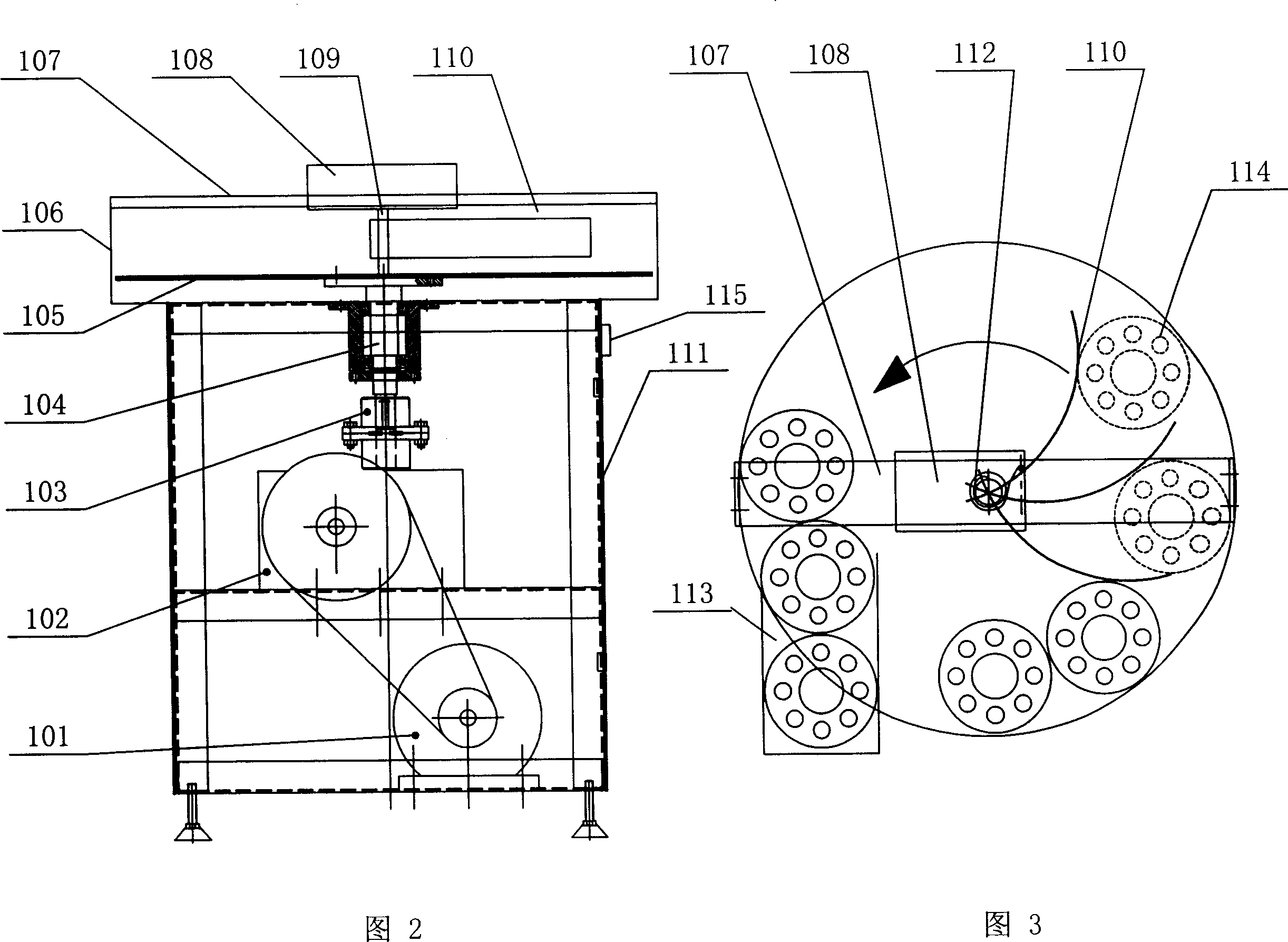

[0067] As shown in Fig. 2 and Fig. 3, automatic feeder 1 is by frame 111, is contained in the charging circular groove 106 above this frame 111, is contained in the disc-shaped bearing feed dish 105 in this charging circular groove 106, The power transmission shaft 104, shaft coupling 103, speed reducer 102, motor 101 that are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com