Belt drive system

一种皮带传动、皮带的技术,应用在传动装置、皮带/链条/齿轮、带有齿的元件等方向,达到减少旋转力矩的降低、防止摆动和侧移、增强效果的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

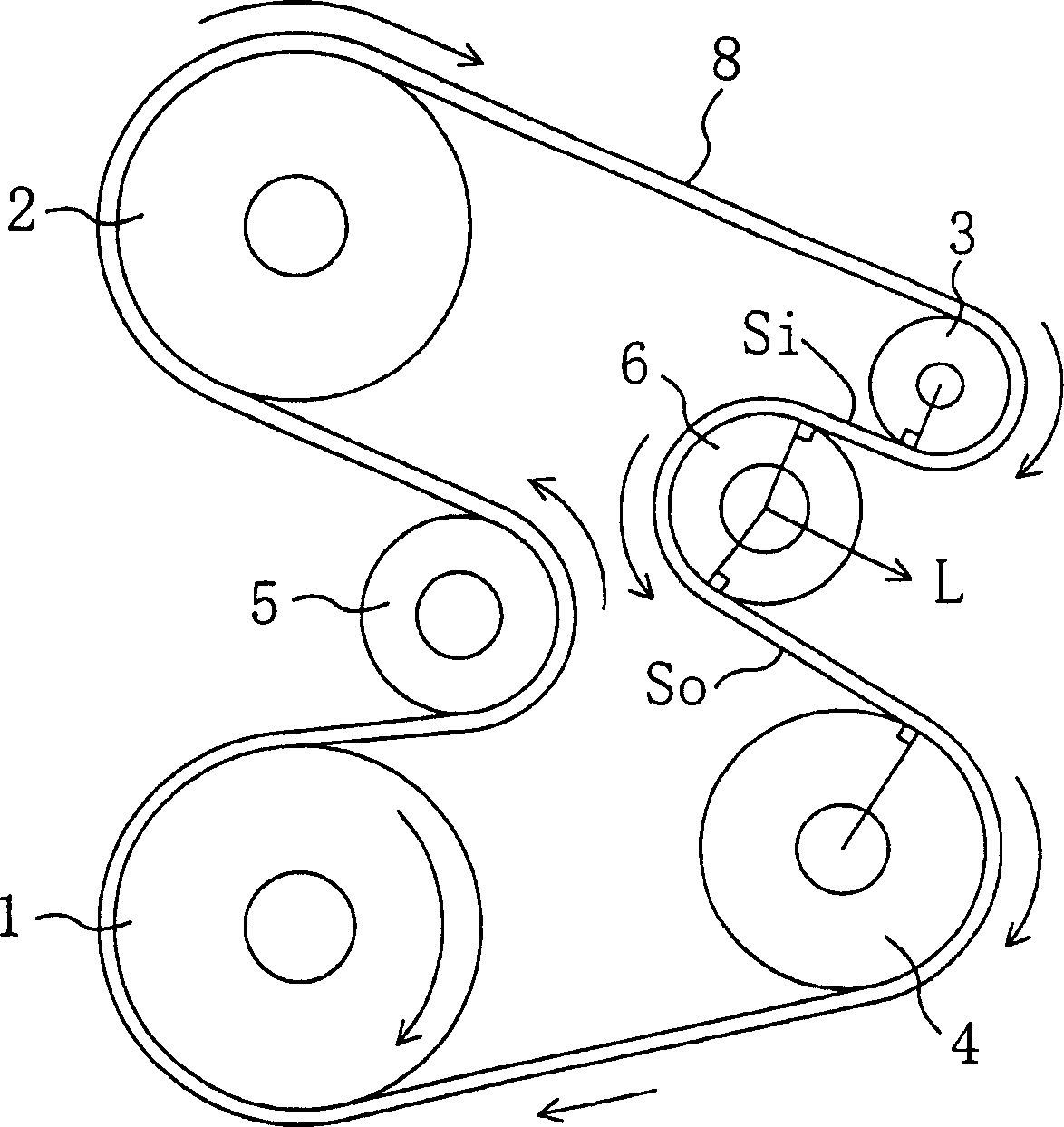

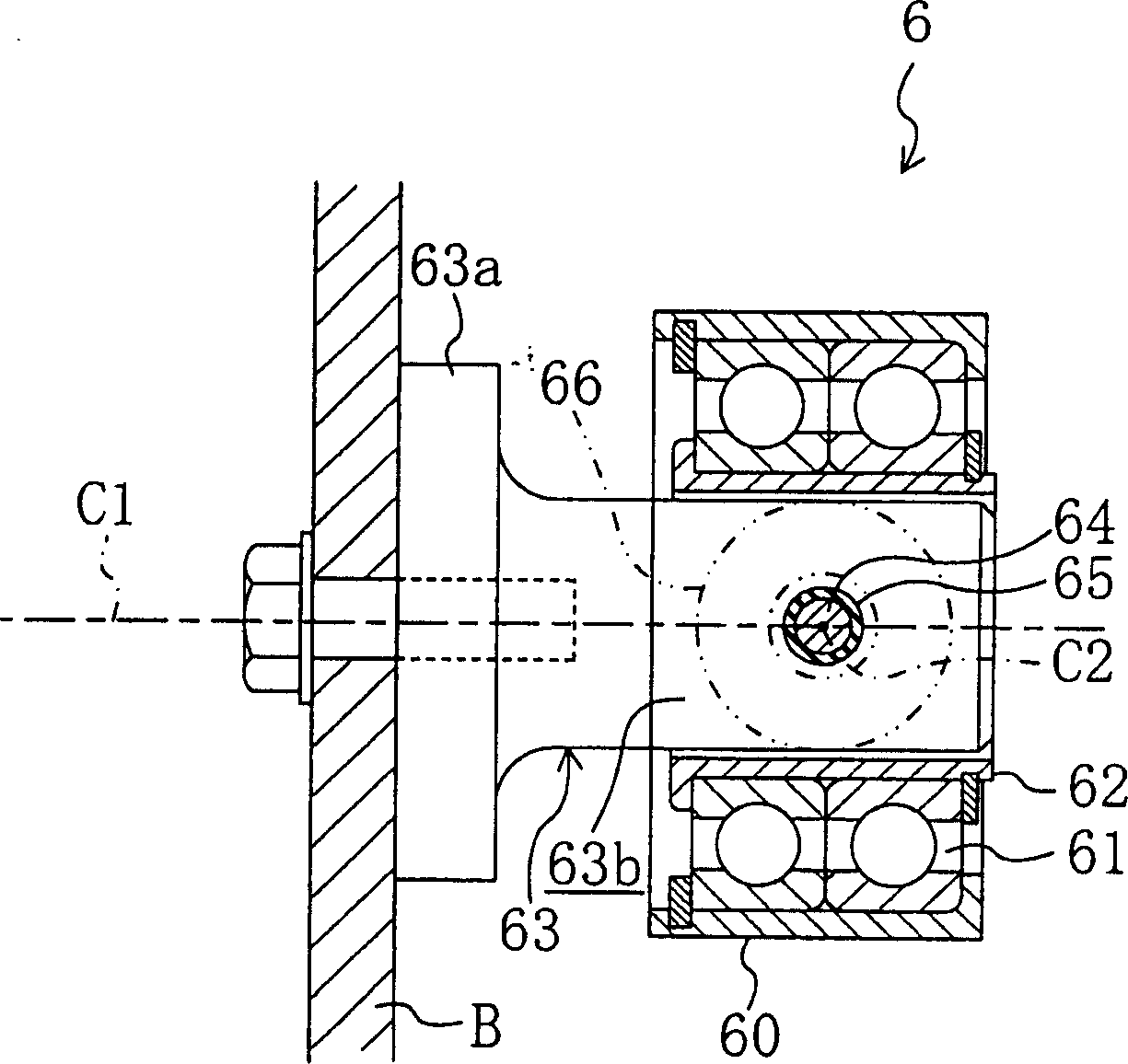

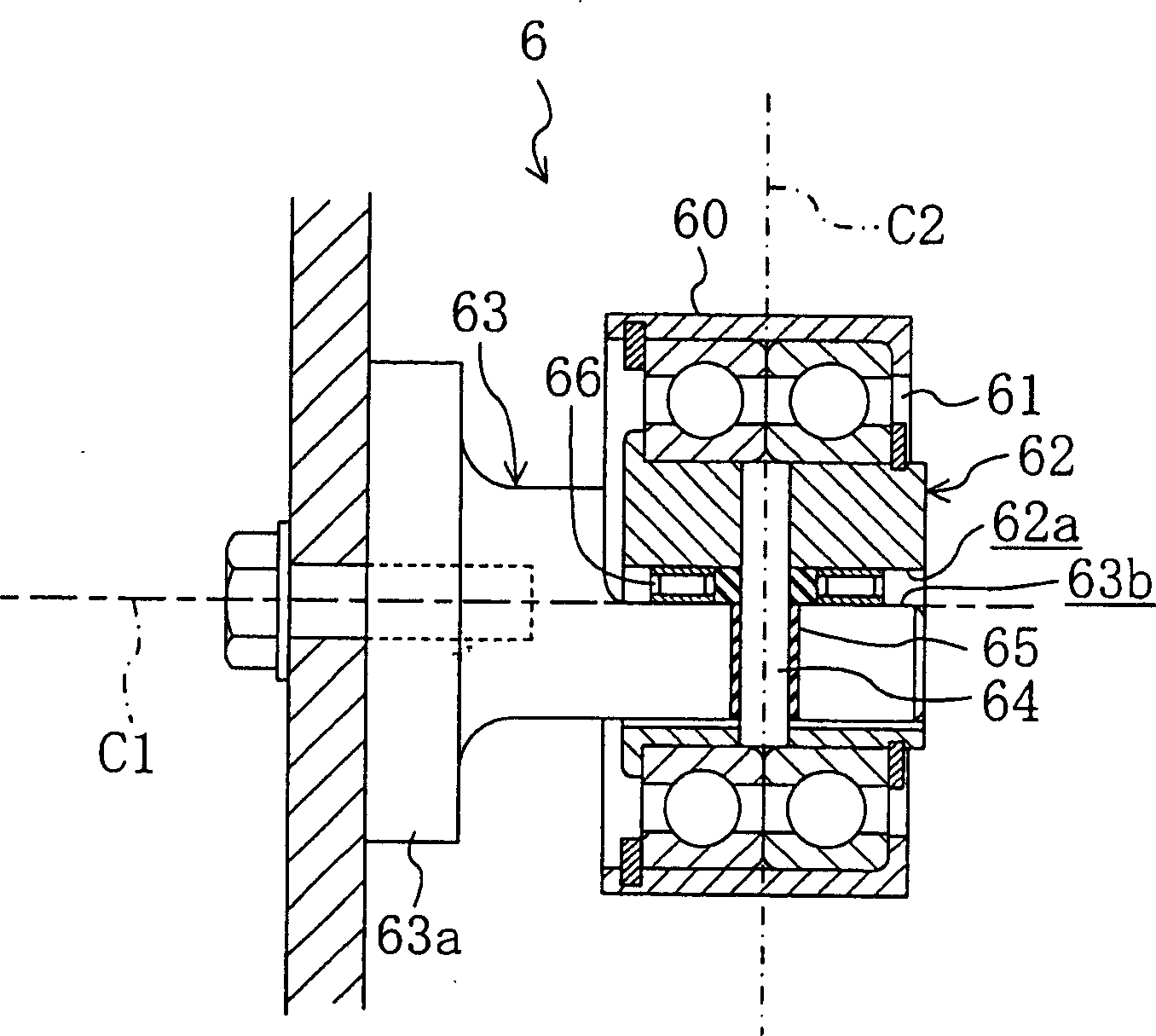

[0053] figure 1 An arrangement diagram of belts and pulleys in which the belt drive system according to the present invention is applied to an engine accessory drive system A is schematically shown. In this figure, reference numeral 1 denotes a crank pulley as a driving pulley mounted on a crankshaft (not shown) of the engine E for integral rotation therewith. Reference numerals 2-6 represent driven pulleys, which include a PS pump pulley 2 that is mounted on a rotating shaft of an accessory power steering pump (not shown) of the engine, and rotates integrally with the rotating shaft; an accessory AC mounted on the engine On the rotating shaft of the generator (not shown), the alternator pulley 3 rotates integrally with the rotating shaft; the air conditioning compressor (not shown) attached to the engine is installed on the rotating shaft, and the comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com