Design method for telescopic beam assembly in hydraulic support

A design method and technology of hydraulic support, which can be applied to pillars/supports, roof beams supporting mine roofs, mining equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

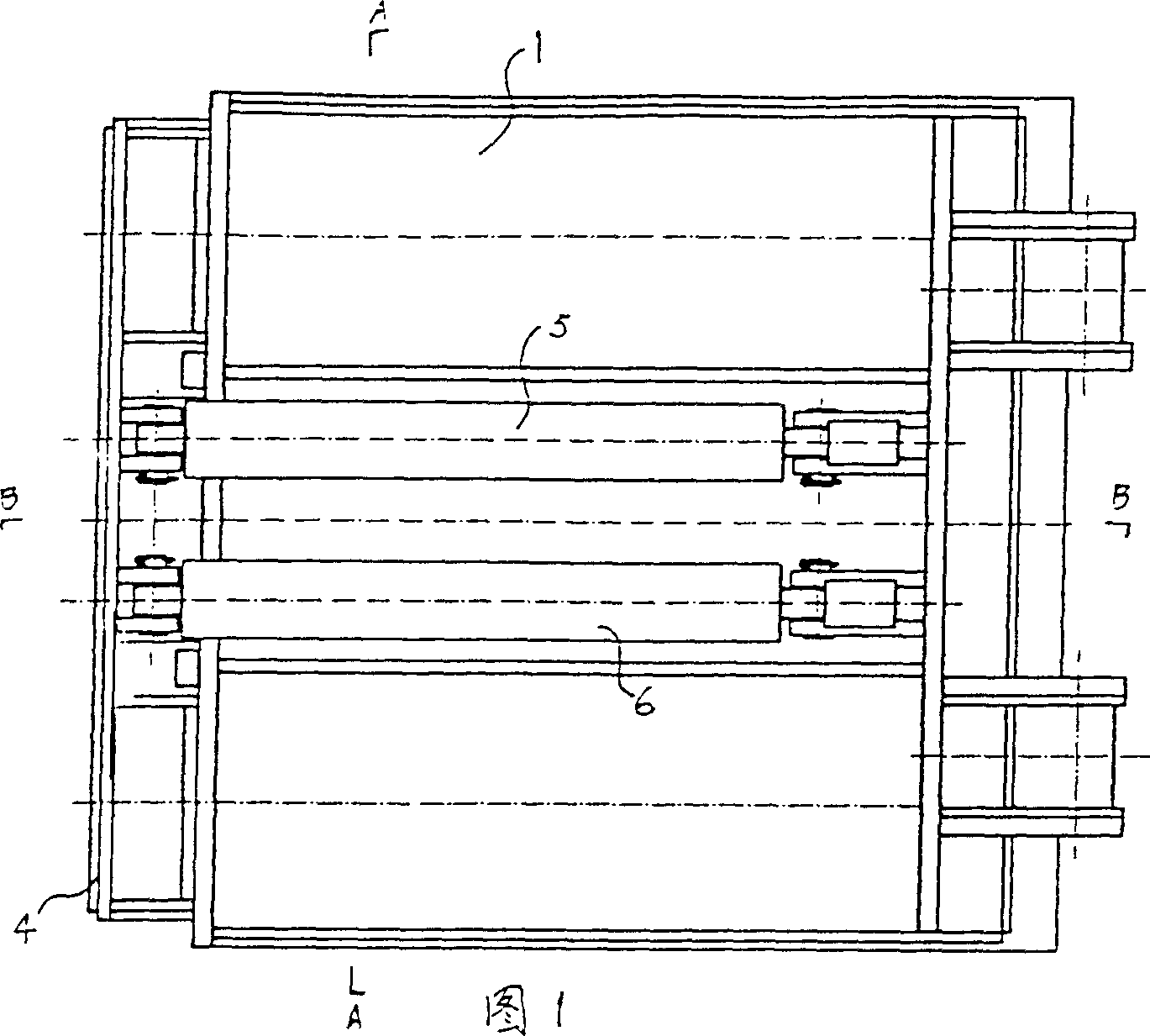

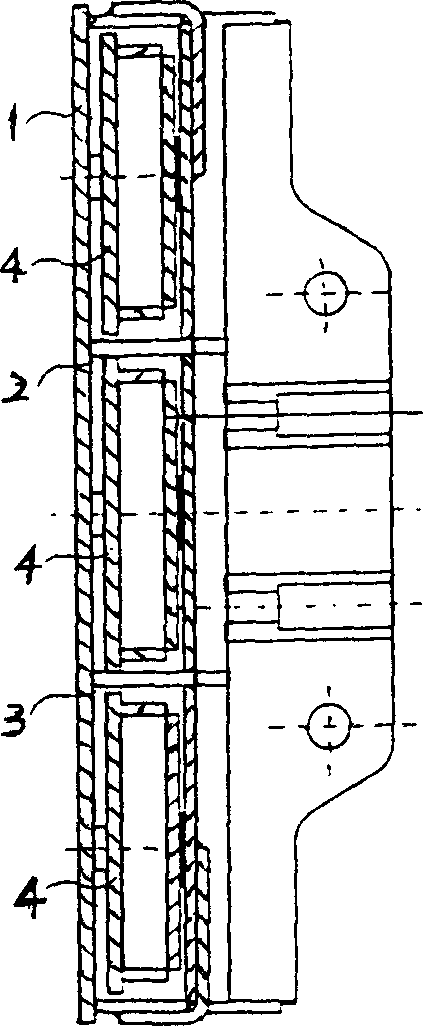

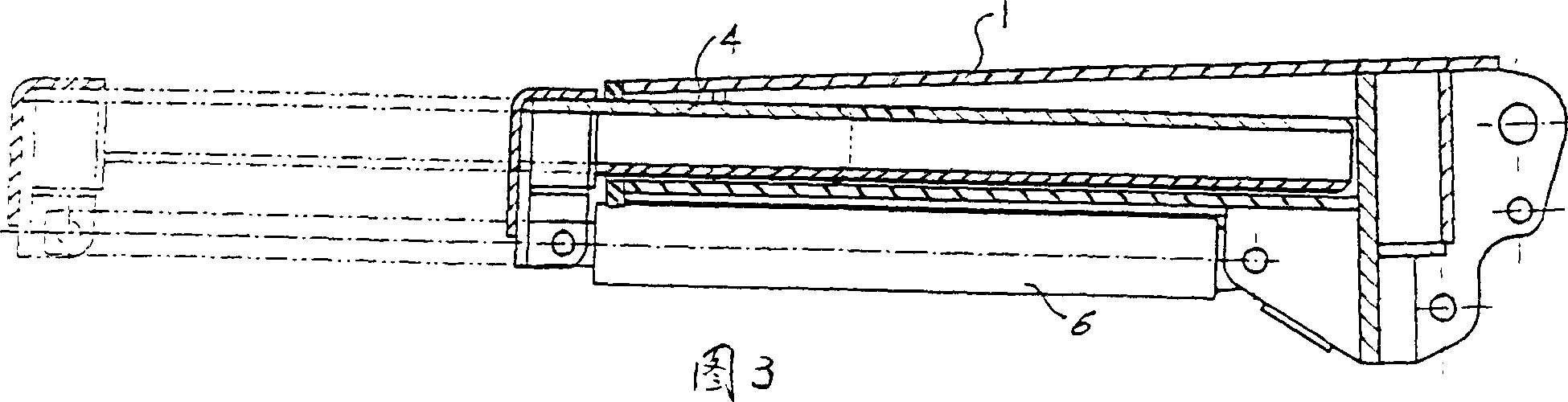

[0012] As shown in the figure, the design method of the telescopic beam assembly in the hydraulic support according to the present invention first sets the top beam 1 as a box-shaped body structure, and two guide partitions are arranged in the box cavity of the top beam 1 along its longitudinal direction. Plates 2 and 3 divide the box cavity into three chambers; a telescopic beam 4 of "E" shape is set in the box cavity of the top beam 1, and two jacks 5 and 6 that drive the expansion and contraction of the telescopic beam 4 are respectively It is arranged in the middle part of the outer surface of the bottom plate of the top beam 1 close to the two guide partitions 2 and 3; between the two sides of the beam plate of the telescopic beam 4 in the middle box cavity of the top beam 1 and the corresponding guide partitions 2 and 3 The fit gap between is less than the fit gap between the two sides of the telescopic beam 4 beam plate in the box cavity on both sides of the top beam 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com