High temperature high pressure oil well cement paste coagulation instrument and its coagulation time measuring method

A technology of oil well cement slurry and measurement method, which is applied in the direction of measurement, earthwork drilling and production, wellbore/well parts, etc. It can solve the problems of unsatisfactory mechanical measurement and non-use, etc., and achieve the effect of convenient operation and difficult measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

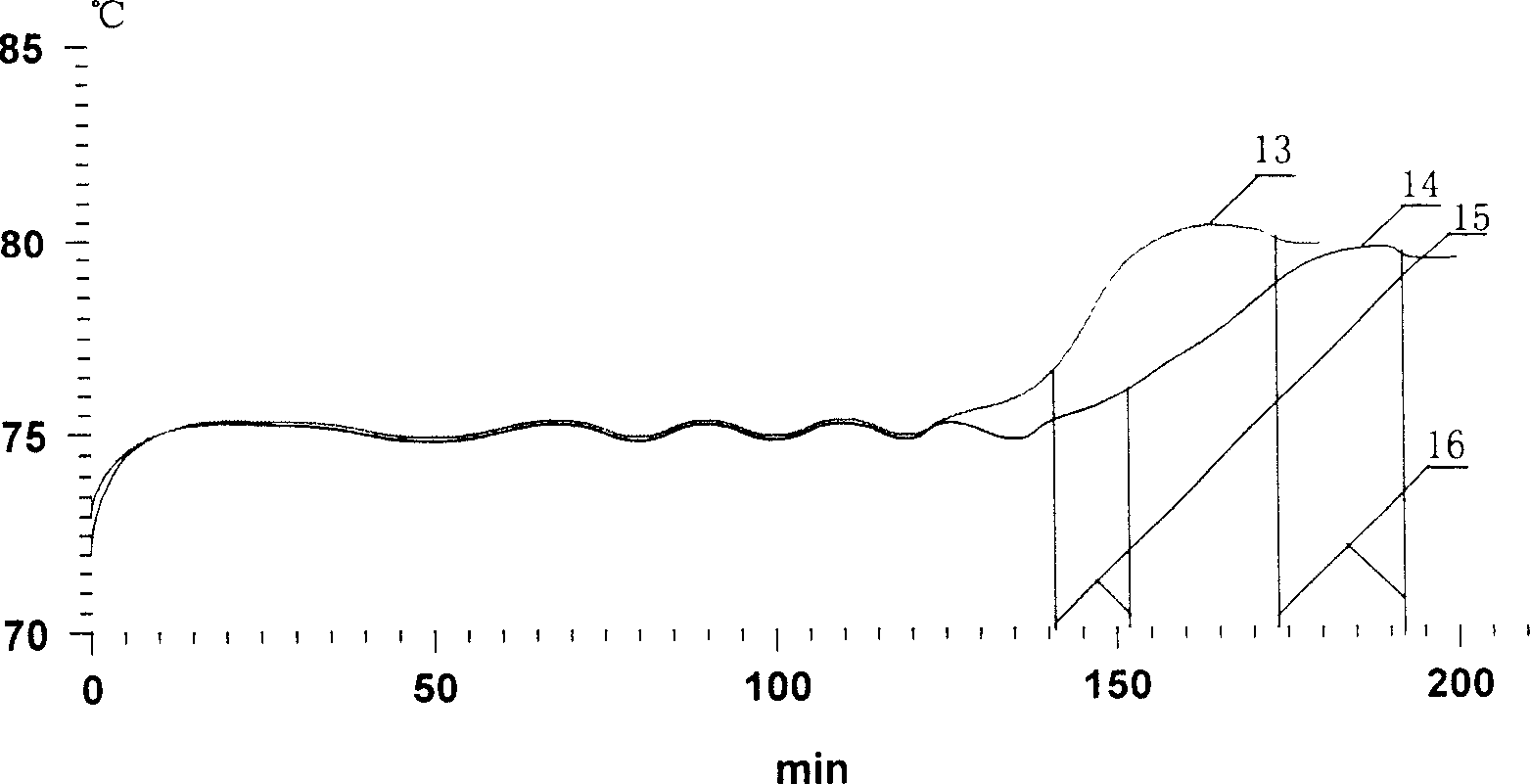

[0027] 1. Prepare three kinds of oil well cement slurries with different properties according to the API standard, and the density is 1.0 / cm 3 (See Table 2);

[0028] 2. According to the annual average surface temperature of 18°C, the geothermal gradient of 2.1°C / 100m, and the well depths of 2000m and 3190m, determine the experimental temperature and pressure of the oil well cement slurry (see Table 2).

[0029] Grout Formula

experiment

temperature

℃

experiment

pressure

MPa

thermometry

initial setting

min

final set

min

the biggest

℃

Grade G cement

0.44

60

37

255

298

4.5

0.44

85

59.5

108

144

5

Grade G cement + 0.2% SXY + 1% LT-2

0.44

60

37

324

388

3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com