Bi-fixation planking curtain

A double-fixed, plate-based technology, applied to walls, building components, buildings, etc., can solve problems such as high cost, easy deformation, and poor firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

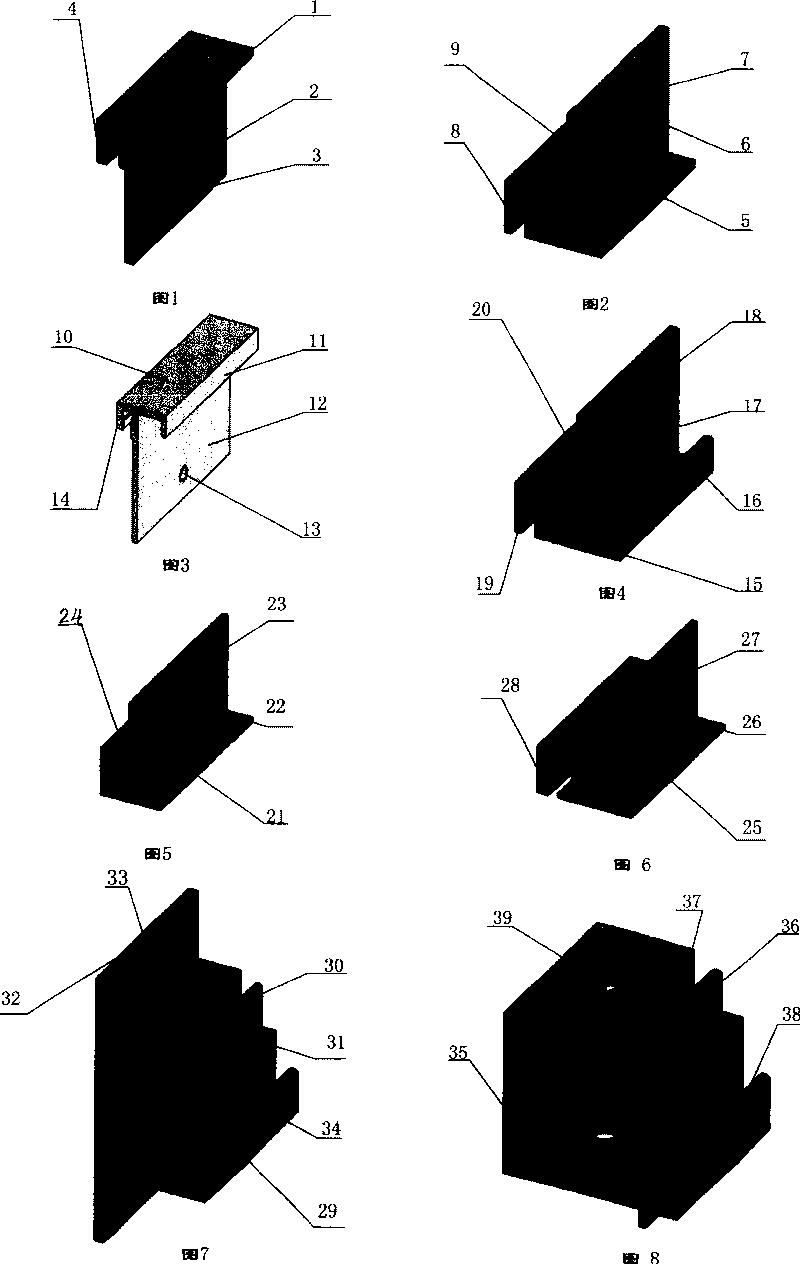

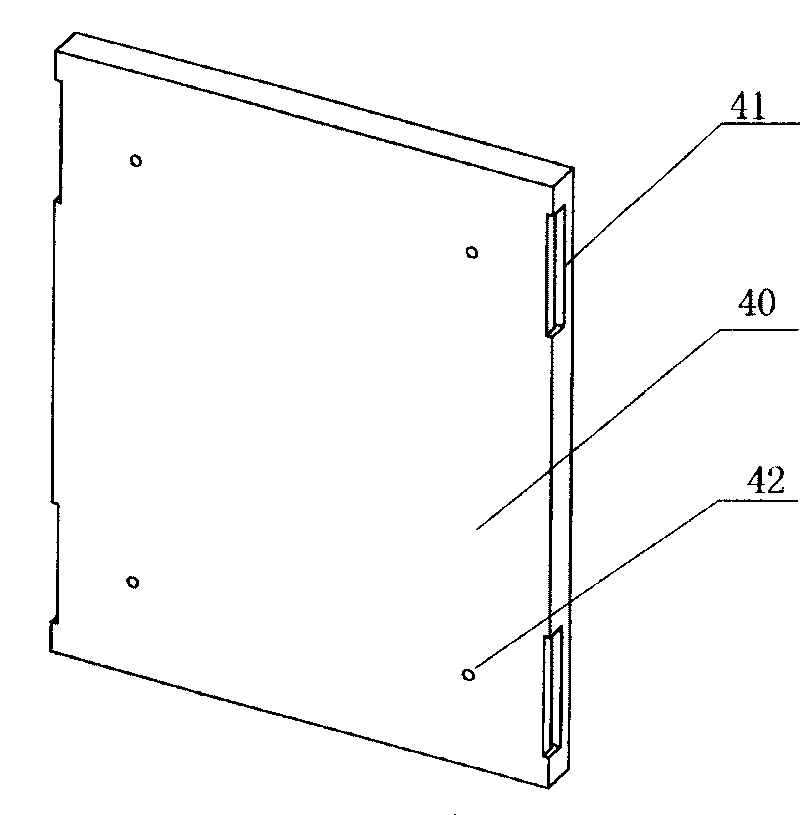

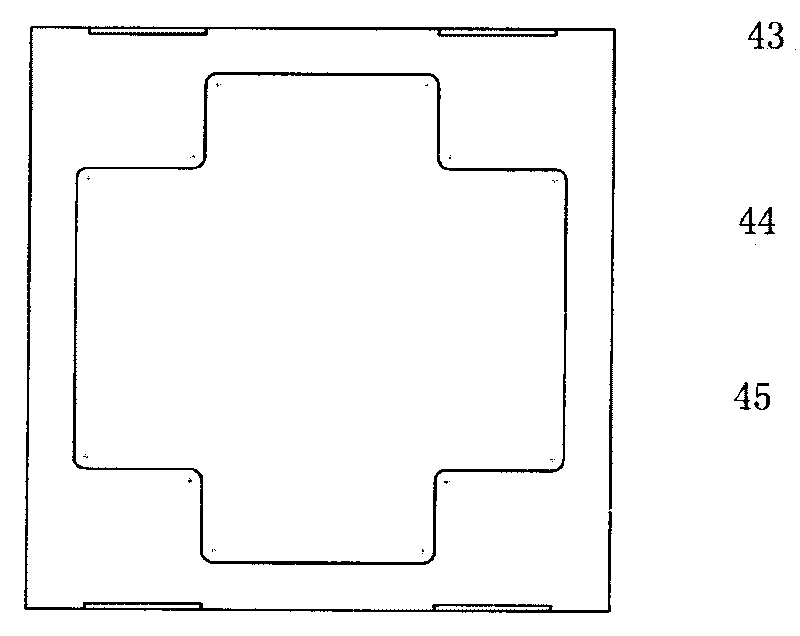

[0039] A double fixed panel curtain wall assembly such as Figure 1-Figure 10 as shown, figure 1 It is the bracket to fix the upper plate pendant, figure 2 It is the bracket to fix the lower plate pendant, image 3 It is the connecting hook to fix the upper plate pendant, Figure 4 It is the connecting hook to fix the lower plate pendant, Figure 5 It is a frame-type fixed upper plate pendant profile, Image 6 It is a frame-type fixed lower plate pendant profile, Figure 7 is the rear fixed plate pendant, Figure 8 is a bolt post-fixed sheet metal pendant, Figure 9 is a stone slab, Figure 10 It's a clay slab. figure 1 Middle: 1 is the supporting plate, 2 is the back board, 3 is the anchor bolt hole, and 4 is the rear hook. figure 2 Middle: 5 is the lower supporting plate, 6 is the back plate, 7 is the anchor bolt hole, 8 is the rear hook, and 9 is the height adjustment threaded hole. image 3 Middle: 10 is supporting plate, and 11 is upper supporting plate hook, ...

Embodiment 2

[0041] The three-dimensional assembly diagram of a frame-type panel curtain wall is as follows Figure 11 as shown, Figure 12 It is an exploded view of the three-dimensional assembly of the framed panel curtain wall. Among them: 21 is the upper support plate of the frame, 25 is the lower support plate of the frame, 29 is the lower ladder support plate of the rear fixed plate pendant, 30 is the upper ladder support plate of the rear fixed plate pendant, 31 is the anti-loosening groove of the upper ladder support plate, and 32 is The back board, 33 is the back connecting hole, 34 is the anti-off threaded hole, 48 is the supporting plate frame, 49 is the slate, 50 is the curtain wall keel, and 51 is the keel connecting plate.

[0042]During assembly, the keel connecting plate 51 is welded on the curtain wall keel 50, the rear fixing plate hanger is connected to the keel connecting plate 51 with bolts, and the stone plate 49 is glued to the supporting plate frame 48 composed of ...

Embodiment 3

[0044] A three-dimensional assembly diagram of a stone curtain wall fixed by a pallet Figure 13 as shown, Figure 14 It is an exploded view of the three-dimensional assembly of the stone curtain wall fixed by the pallet. Among them: 1 is the supporting plate for fixing the upper plate hanging part, 2 is the back plate for fixing the upper plate hanging part on the supporting plate, 3 is the anchor bolt hole for fixing the upper plate hanging part on the supporting plate, 4 is the hook after fixing the upper plate hanging part on the supporting plate, 5 is The supporting plate is used to fix the lower plate hanger, 6 is the back plate for fixing the lower plate hanger, 7 is the anchor bolt hole for the supporting plate to fix the lower plate hanger, 8 is the hook for fixing the lower plate hanger by the supporting plate, and 9 is the supporting plate for fixing Height adjustment threaded hole of the lower panel hanger, 29 is the lower ladder support plate of the rear fixed pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com