Air valve swinging arm shaft with oil pressure unloading plane

A valve rocker arm, rocker arm shaft technology, used in engine components, machines/engines, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

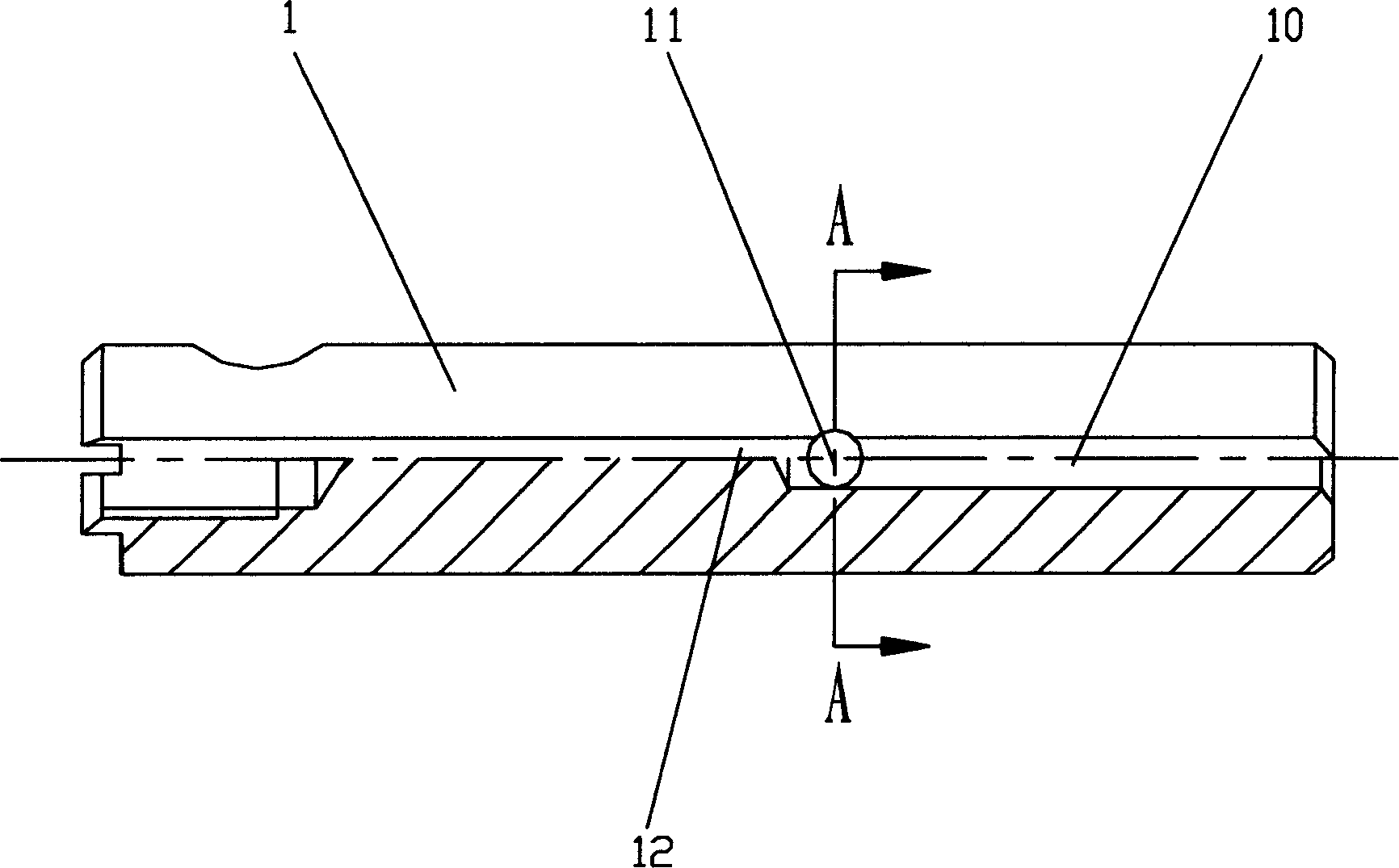

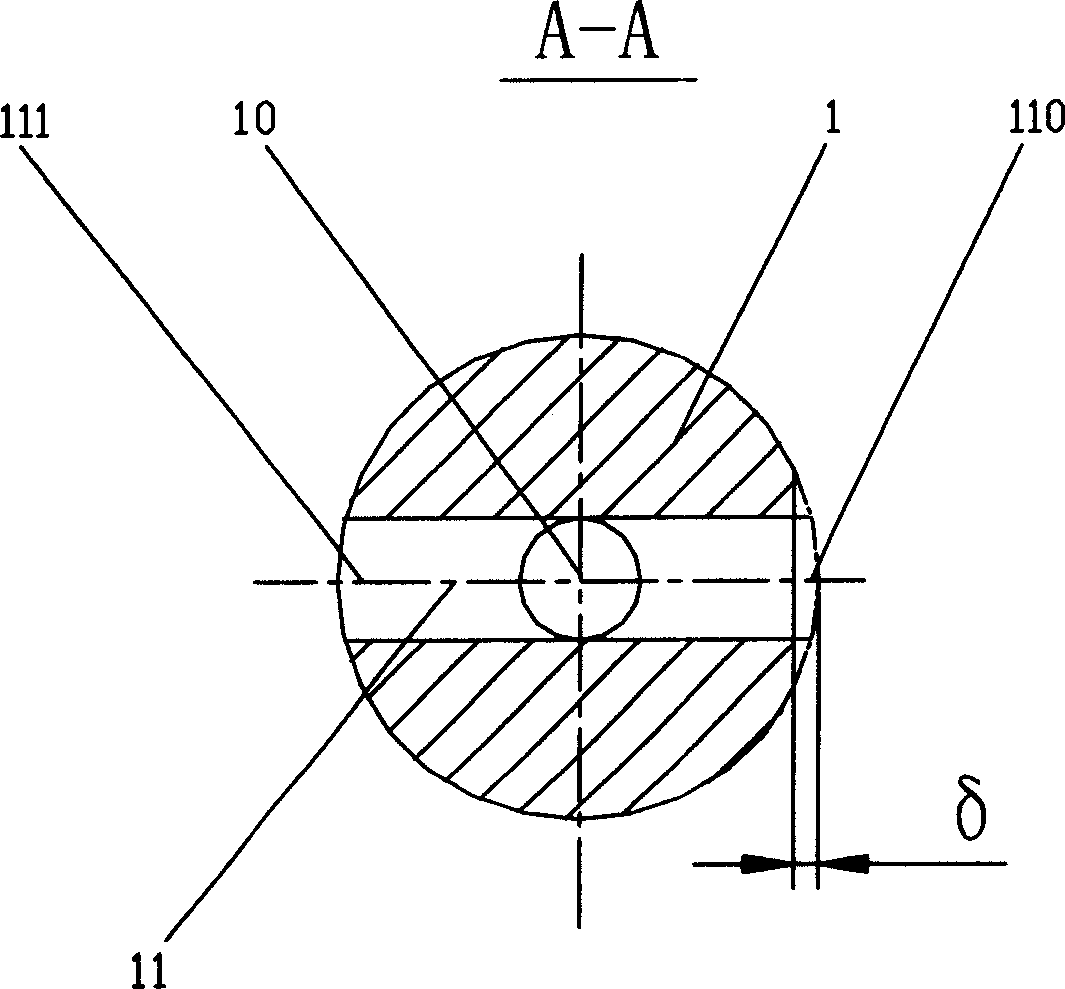

[0010] Such as figure 1 and figure 2 As shown, it is a side view of the rocker shaft of the present invention and a sectional view of the rocker shaft along the A-A direction. The rocker shaft 1 has an axial oil passage 10 along the central axis and a radial oil passage along the radial direction of the rocker shaft. The two ends of the radial oil passage 11 are radial oil passage openings 110, 111, the axial oil passage 10 and the radial oil passage 11 are connected, and the outer surface of the rocker arm shaft 1 has an oil pressure unloading plane 12. The oil pressure unloading plane 12 passes through the radial oil passage port 110 . The purpose of the oil pressure unloading plane 12 is to carry out oil pressure unloading, improve the flow rate of lubricating oil, and lower the temperature. Another radial oil passage port 111 does not offer an unloading plane to enhance the lubricating effect.

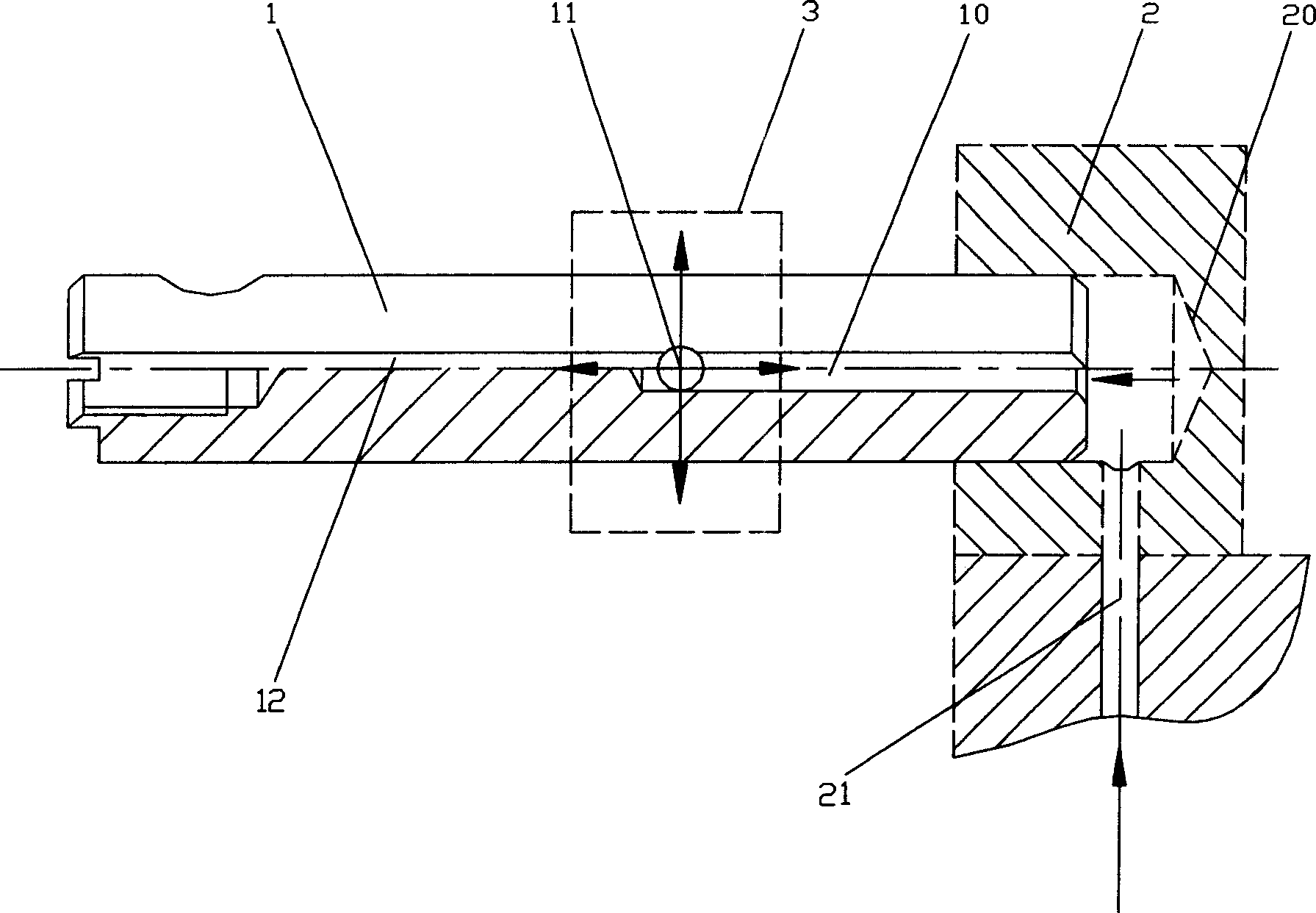

[0011] Such as image 3 Shown is the working schematic diagram of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com