DC inverting electronic ballast

A technology of electronic ballast and electronic switch, which is applied to the use of electric light sources, electrical components, and gas discharge lamps. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

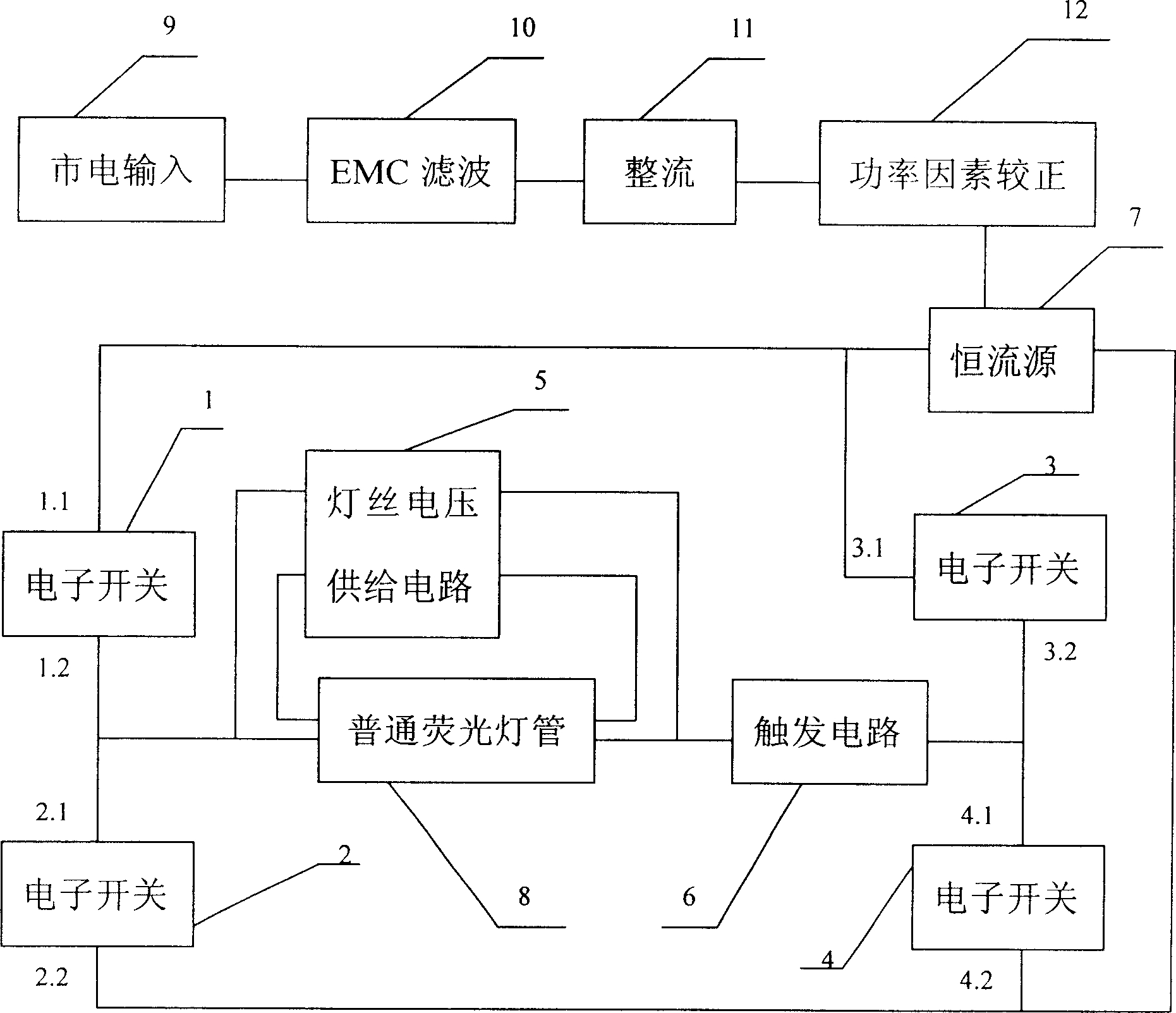

[0016] according to Figure 1 to Figure 6 In the embodiment of the present invention with the above-mentioned structure shown in the DC reverse electronic ballast, 9 strings of mains input are electrically connected to the EMC filter circuit 10, the rectifier circuit 11 and the power factor correction circuit 12 in turn to form a constant current source 7. The common The filaments at both ends of the fluorescent tube 8 are connected in series with a filament voltage supply circuit 5, the right end of the ordinary fluorescent tube 8 is respectively connected to the terminal 3.2 of the electronic switch 3 and the terminal 4.1 of the electronic switch 4 through the trigger circuit 6, and the left end of the ordinary fluorescent tube 8 is respectively connected to the terminal of the electronic switch 1 Terminal 1.2 and terminal 2.1 of the electronic switch 2, terminal 1.1 of the above-mentioned electronic switch 1 and terminal 3.1 of the electronic switch 3 are all electrically co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com