Filming device and method of glass substrate

A technology for glass substrates and coating devices, which is applied in the manufacturing of electrical components, circuits, semiconductor/solid-state devices, etc., and can solve the problems of film cutting length deviation, vibration, and inflow of foreign objects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Hereinafter, a glass substrate coating device according to a preferred embodiment of the present invention will be described in detail with reference to the drawings.

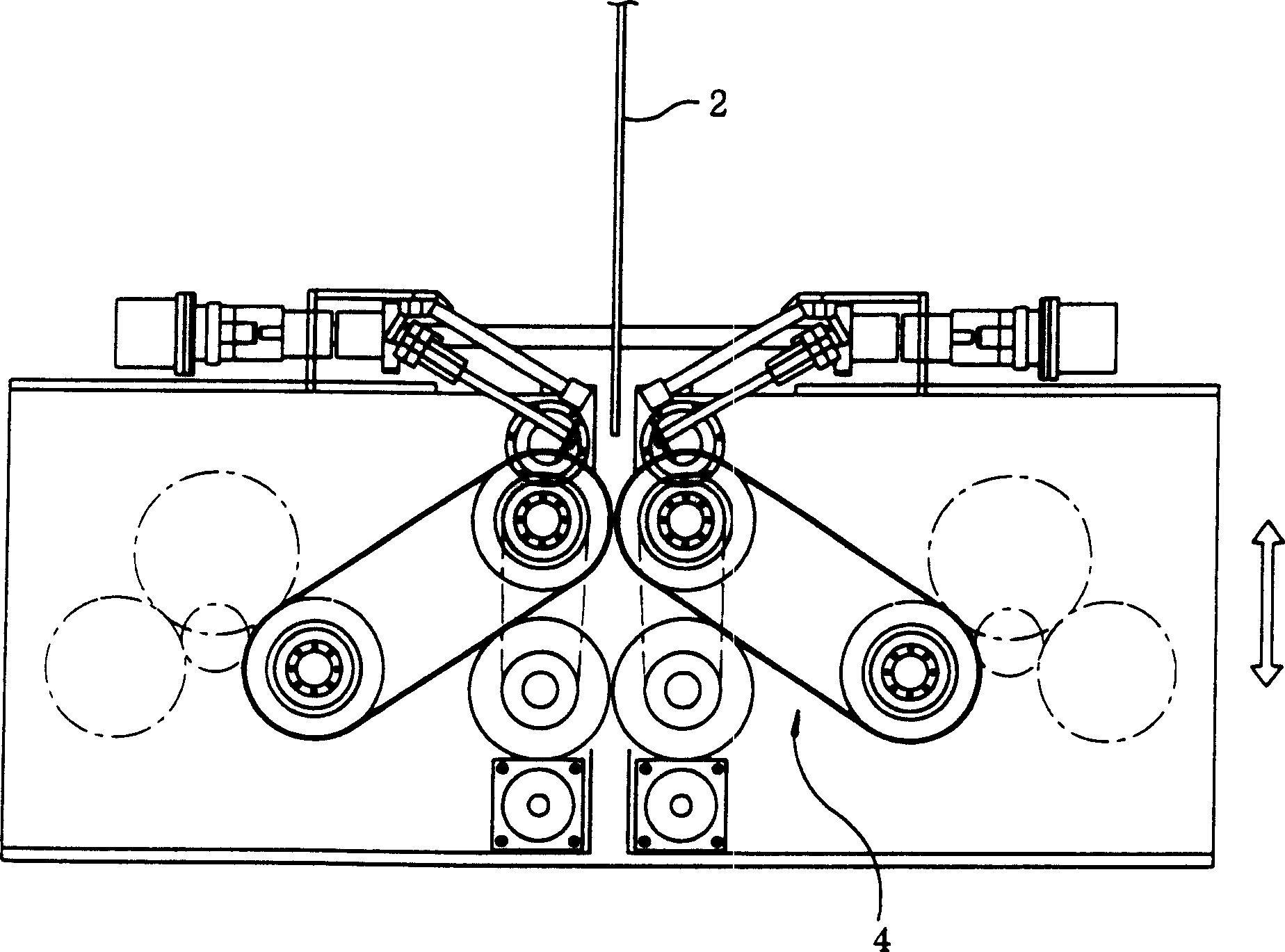

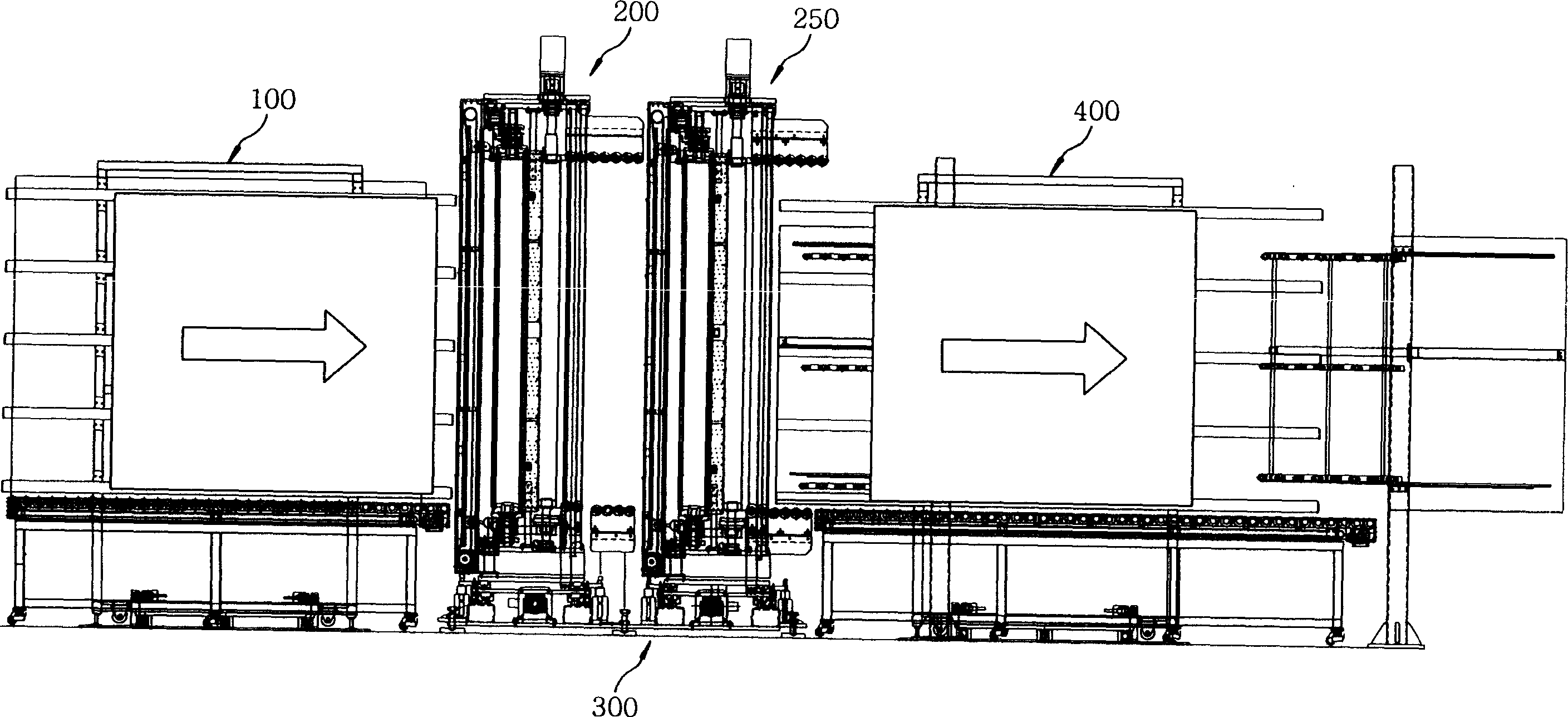

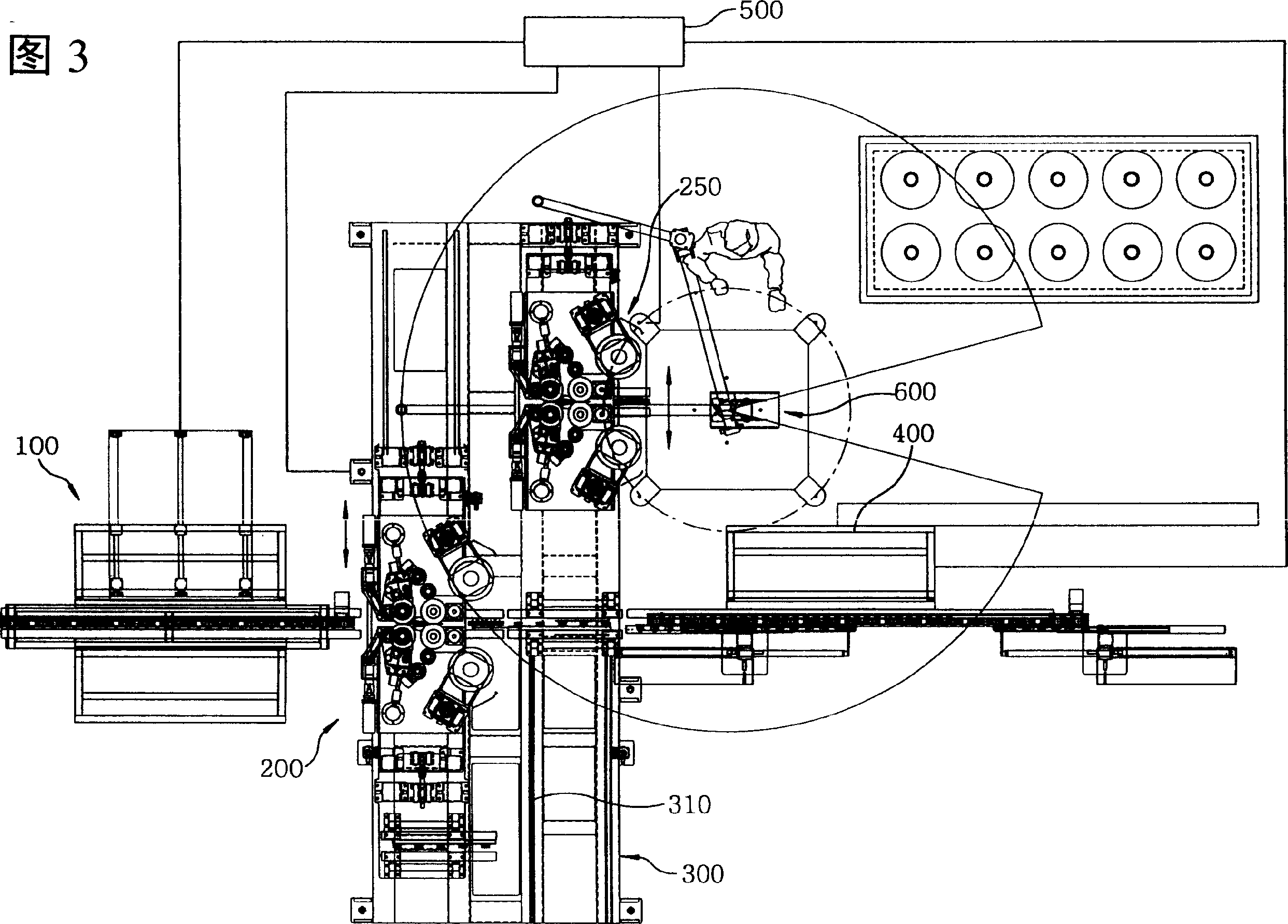

[0012] figure 2 and FIG. 3 is a front view and a top view of a glass substrate film coating device according to a preferred embodiment of the present invention. As shown in the figure, the glass substrate coating device of the present invention includes: a loading conveyor 100, which floats the glass substrate with air in a vertical state on both sides without contact, and conveys it in one direction; the first and second film applicators 200, 250, they are configured on a straight line with the loading conveyor 100 and are vertically arranged so as to simultaneously coat the film on both sides of the glass substrate in a vertical state discharged from the loading conveyor 100; 1 and the second film applicator 200, 250 are conveyed between the film roll supply position and the coating position respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com