Sail type net mouth scissoring and assembling method

An assembly method and net port technology, applied in fishing, application, animal husbandry, etc., can solve problems such as uneven force on nets, increase in net line area, and damage to nets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The best way to implement the present invention is illustrated below in conjunction with the accompanying drawings:

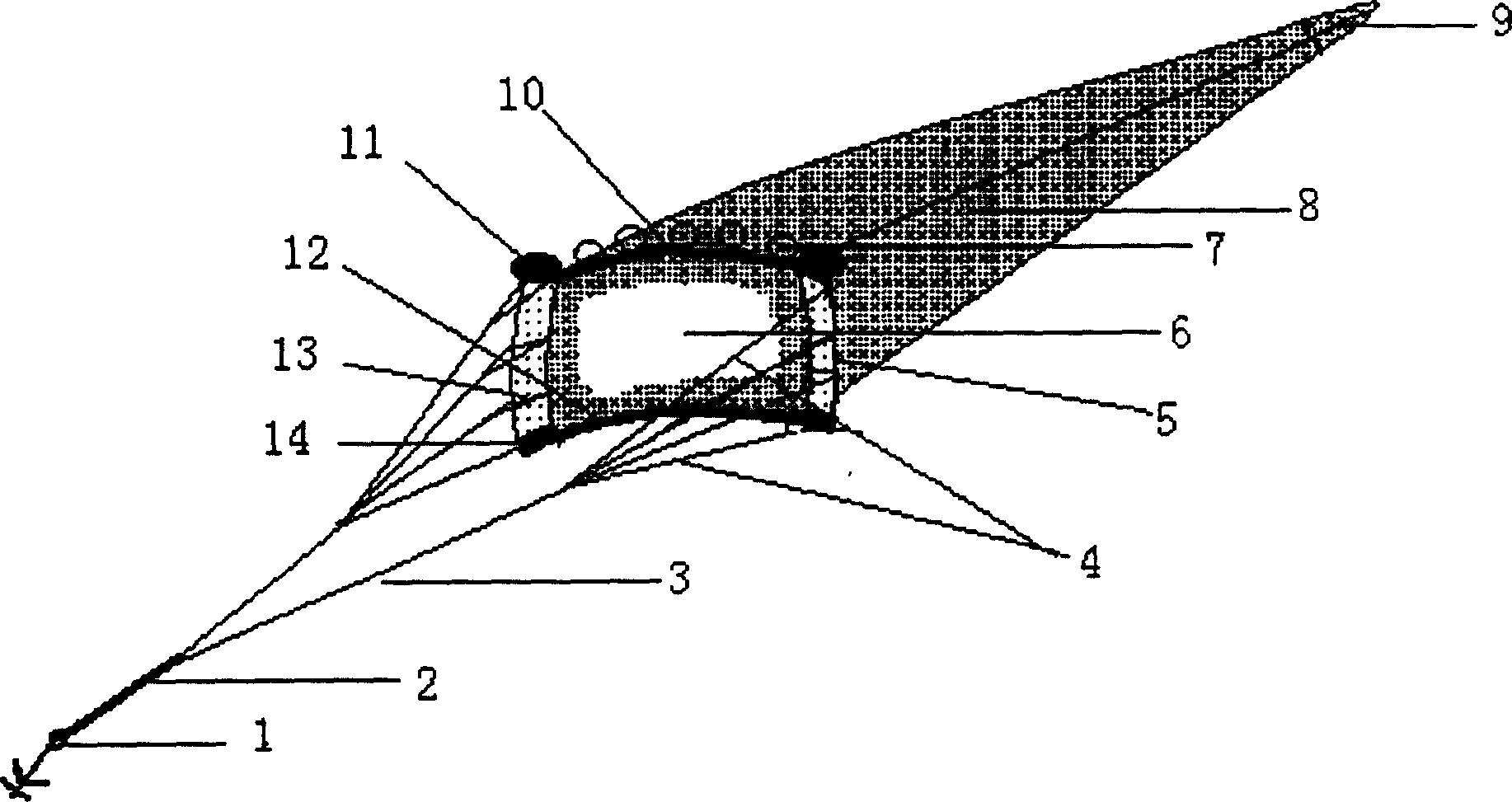

[0012] figure 1 Indicates that the sail-type netting adopts anchor 1, anchor cable 2, drag line 3, fork line 4, cross bar 13, expanded canvas 5, floater 7, floating ball 11, sinker 14, upper line 10, lower line 12, net body 8. The mesh bag 9 is assembled and composed; 6 in the figure represents the mesh port.

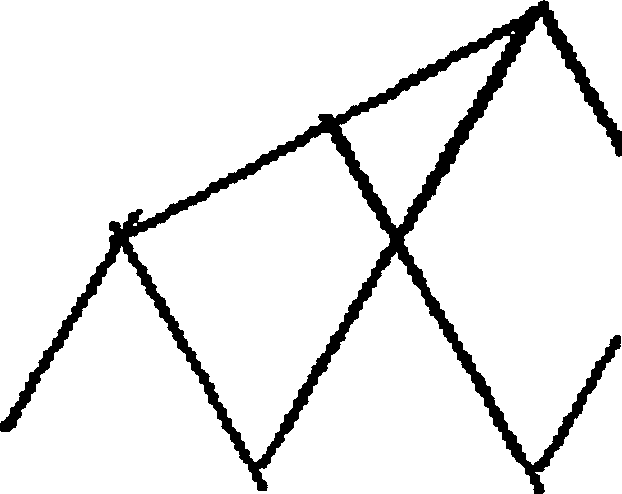

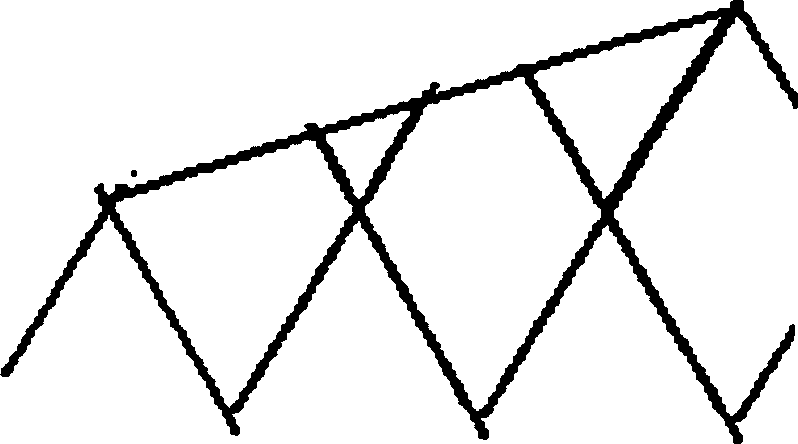

[0013] figure 2 , image 3 , Figure 4 The rhombus in the figure represents the mesh of the mesh, and the slash at the top of the mesh represents the cutting line;

[0014] Figure 5 Indicates the specific cutting method of the dorsal and ventral mesh, because the mesh opening is left and right symmetrical, so Figure 5 Expressed in its half only, Figure 5 It means that the mesh used at both ends of the mesh at the mesh mouth is left with 10 meshes, and then the mesh ports of 43 meshes in the height direction are cut to the middle accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com