Balance system for single cylinder engine

A technology for balancing systems, balancing components, applied in the direction of machines/engines, counterweights, mechanical equipment, etc., can solve problems such as increased cost and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

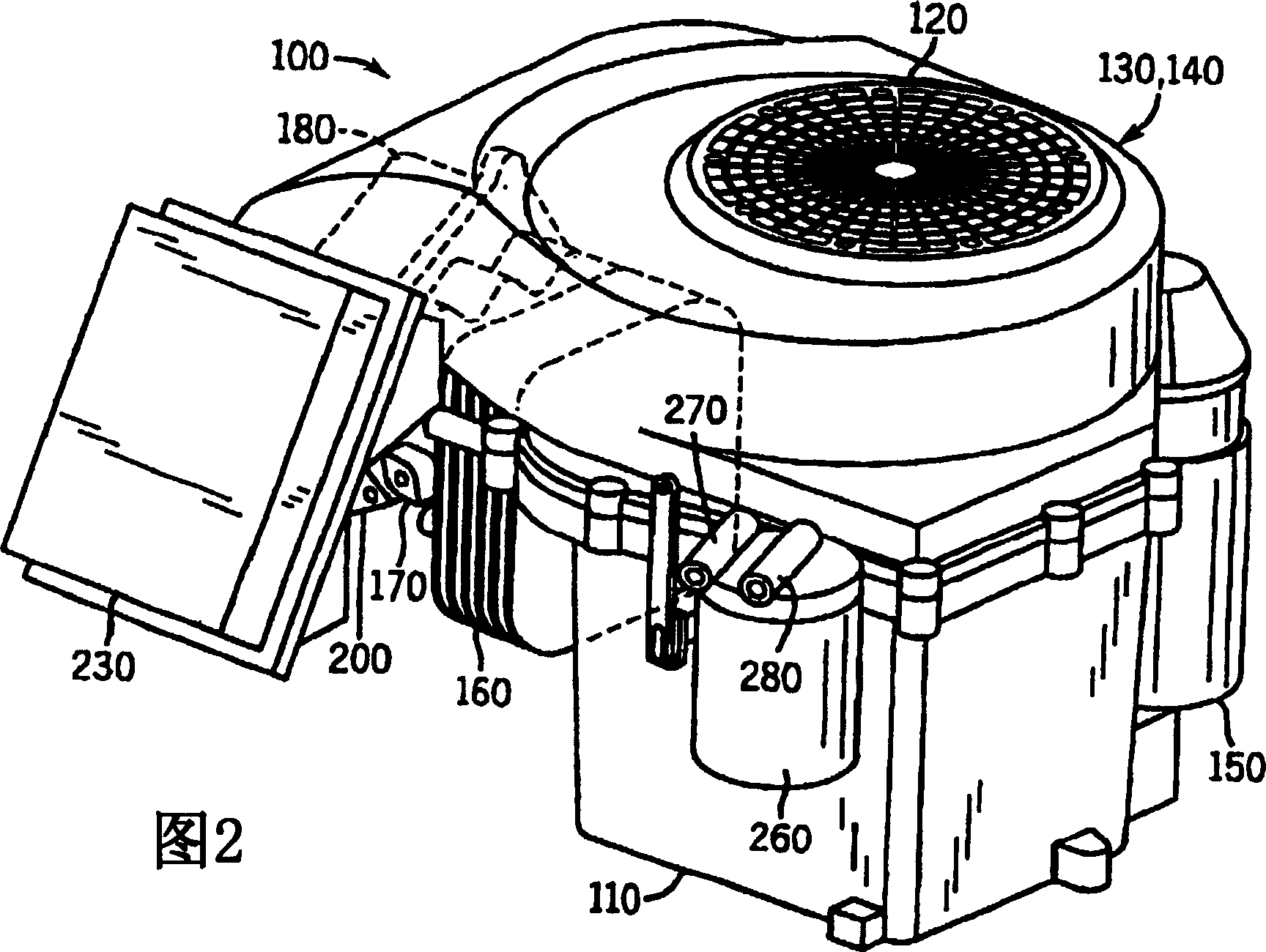

[0029] Referring to FIGS. 1 and 2 , a novel single-cylinder four-stroke internal combustion engine 100 designed by Kohler Co. of Kohler, Wisconsin includes a crankcase 110 and a fan case 120 with a fan 130 and a flywheel 140 inside the fan case 120 . The engine 100 also includes a starter 150 , a cylinder 160 , a cylinder head 170 and a rocker cover 180 . The exhaust port 190 illustrated in FIG. 1 and the intake port 200 illustrated in FIG. 2 are connected to the cylinder head 170 . As is well known in the art, during operation of engine 100 , piston 210 (see FIG. 7 ) moves back and forth within cylinder 160 , towards and away from cylinder head 170 . Movement of the piston 210 thereby causes rotation of the crankshaft 220 (see FIG. 7 ), as well as rotation of the fan 130 and flywheel 140 connected to the crankshaft. Rotation of fan 130 cools the engine and rotation of flywheel 140 maintains a relatively constant rotational momentum.

[0030]Referring specifically to FIG. 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com