Magnetron cathode assembly

A magnetron cathode and component technology, which is applied to the cathode of magnetron, multi-cavity magnetron, and time-of-flight electron tube, and can solve the problems of poor precision and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

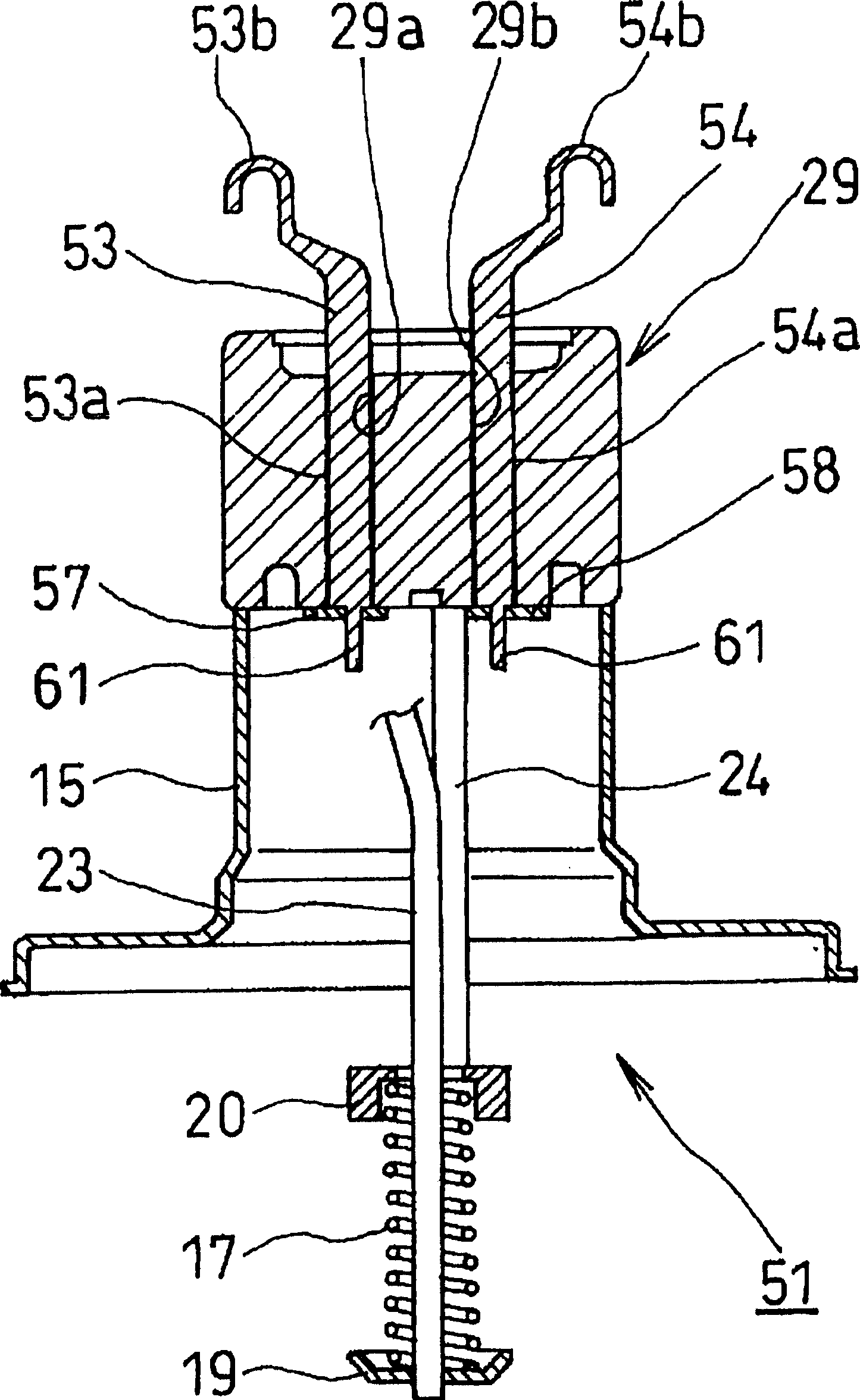

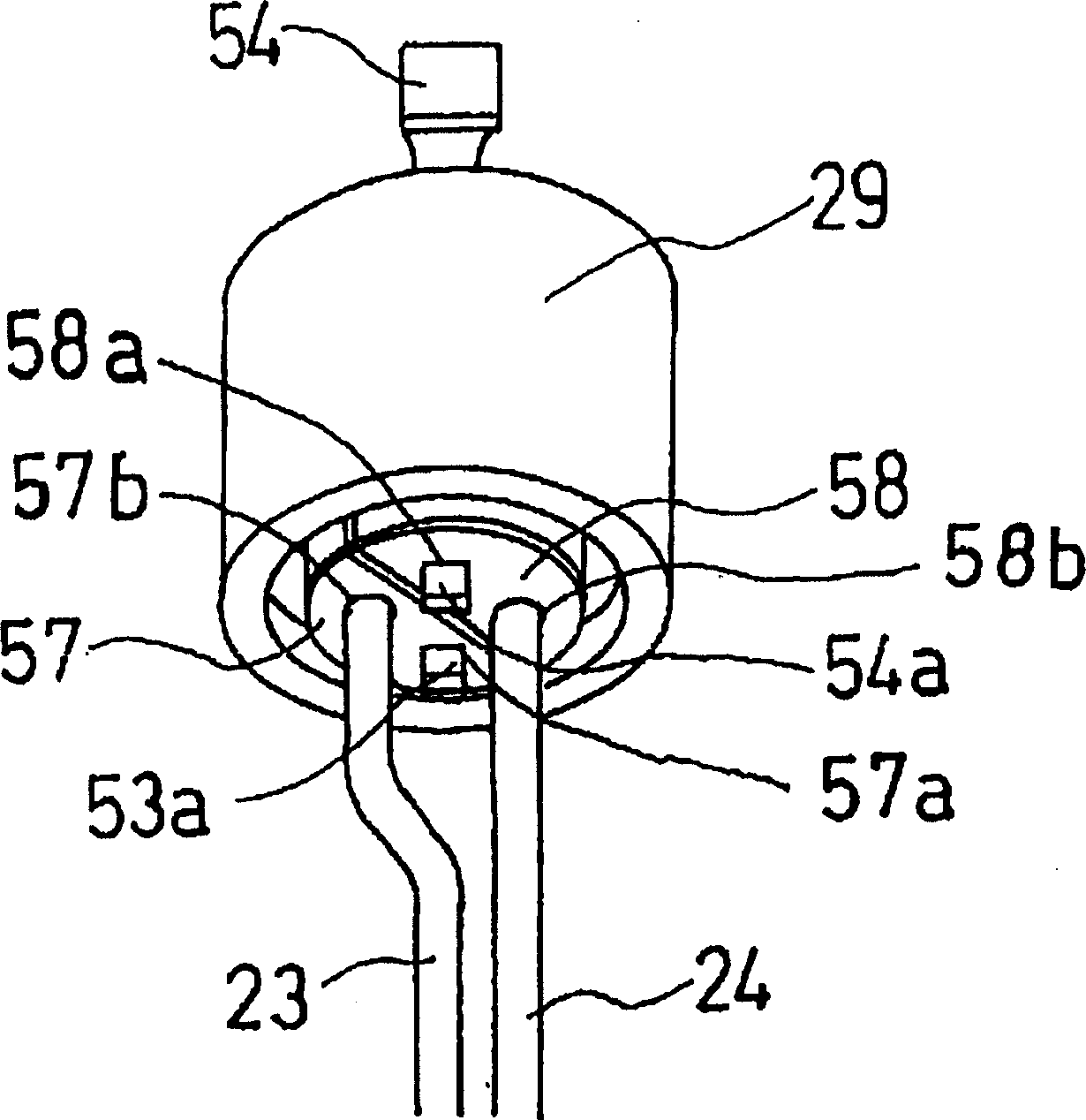

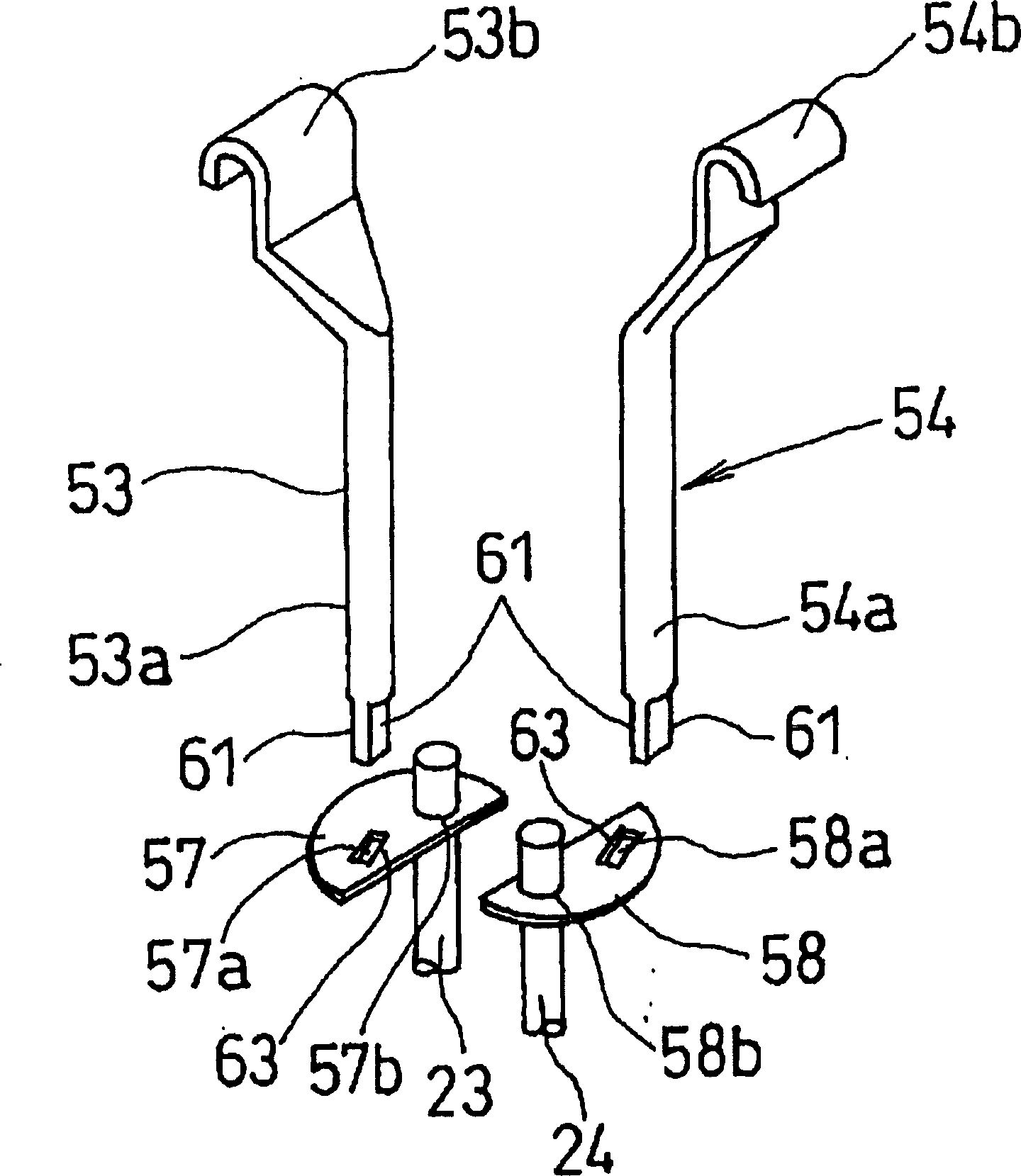

[0041] Preferred embodiments of the magnetron cathode assembly according to the present invention will be described in detail below with reference to the accompanying drawings.

[0042] figure 1 One embodiment of a magnetron cathode assembly according to the invention is shown.

[0043] The magnetron cathode assembly 51 in this embodiment is used for magnetrons employed in microwave heating equipment such as electric ovens. The magnetron cathode assembly 51 comprises: a metal tube 15 joined to the open end edge of the anode block, coaxial with the anode block and forming part of a vacuum vessel; a coil-shaped cathode 17 arranged on the axis of the cathode block Part; a pair of cathode terminal leads 23 and 24, which support the cathode 17 through end caps 19 and 20, which are bonded to the leading ends of the cathode 17; a rod insulator 29, which is hermetically bonded to the metal tube 15, and has a pair of through holes 29a and 29b passing through the rod insulator 29 alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com