End set multi roller grinder

A mill and roller technology, which is applied in the field of material grinding equipment, can solve the problems of grinding drum beating or vibration and noise, low production efficiency, high manufacturing cost, etc., and achieve reduced noise, stable operation, reduced friction and wear and power The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

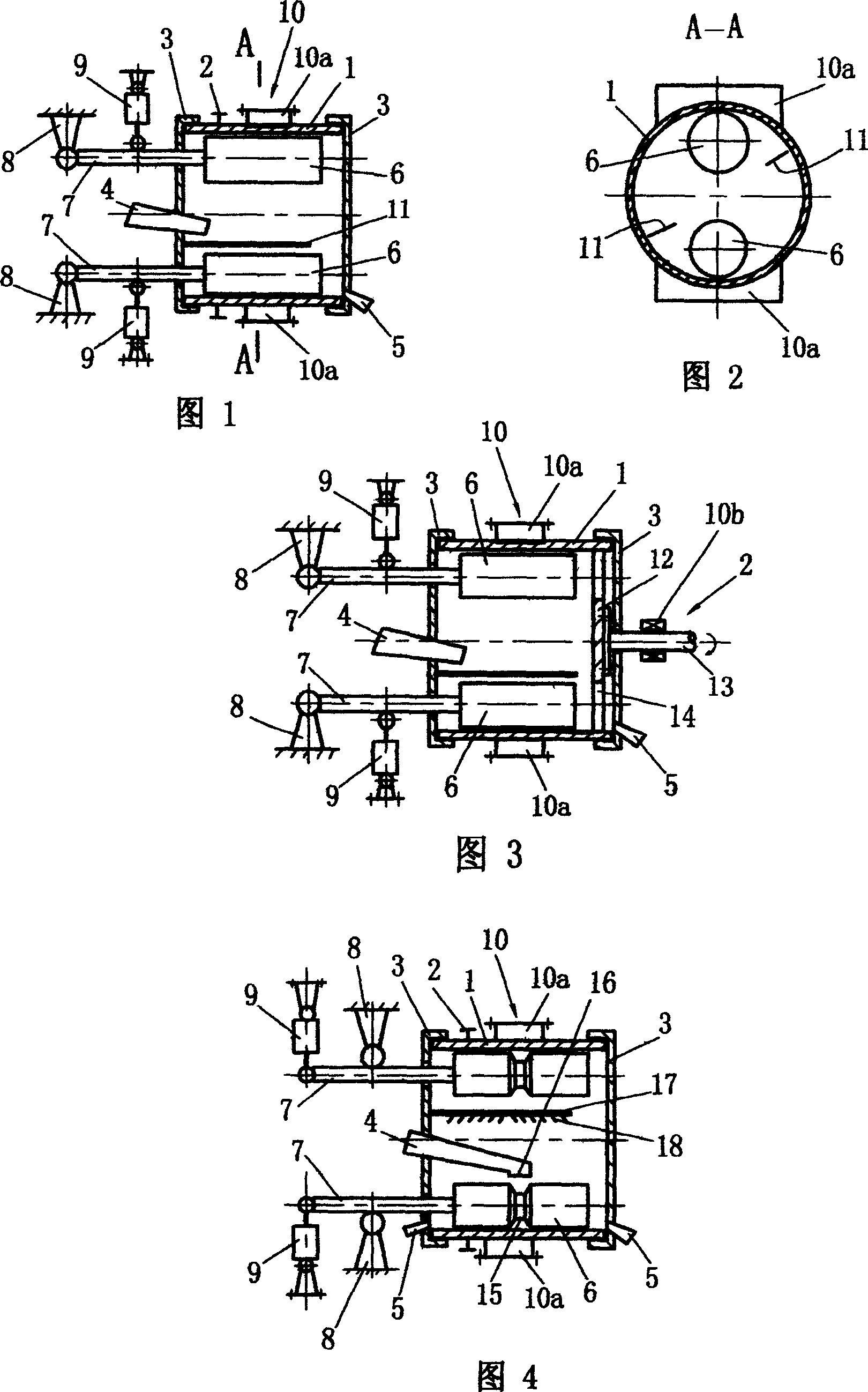

[0018] Embodiment 1, see Fig. 1, Fig. 2.

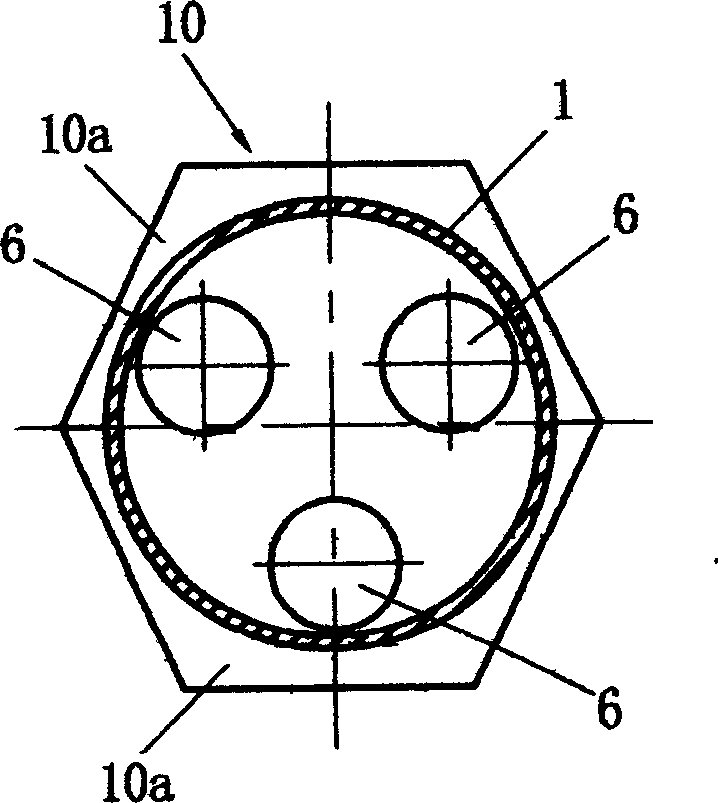

[0019] There are a grinding cylinder 1 and a grinding cylinder driving mechanism 2. There are end caps 3 at both ends of the grinding cylinder, and a feeding device 4 and a discharge port 5 are provided on the end side of the grinding cylinder. Inside the grinding cylinder 1 are grinding mills distributed along the circumferential direction of the grinding cylinder. Roller 6, when the driving mechanism is working, the grinding cylinder can rotate relative to the end cover; the driving mechanism 2 in this example is a gear-type driving mechanism, and there are two grinding rollers 6 inside the grinding cylinder 1, which are shown along the circumferential direction of the grinding cylinder Evenly distributed, that is, symmetrical up and down, each grinding roller and the inner wall of the grinding cylinder form a complete grinding surface, one end of each grinding roller 6 is connected to a roller shaft 7, and the outer section of each ...

Embodiment 2

[0020] Embodiment 2, see Fig. 3.

[0021] The driving mechanism of this example adopts another kind of structure to realize. As shown in Figure 3, the driving mechanism 2 is a transmission shaft type structure, including a component 12 that is located in the grinding cylinder 1 and connected to the end of the grinding cylinder, and a transmission shaft 13 connected with the component. The shaft 13 protrudes from the end cover 3 of this side; the transmission shaft 13 is provided with a supporting device 10b constraining the circumferential direction of the grinding cylinder, that is, the supporting system 10 of this example consists of a support system 10b located on the outer wall of the grinding cylinder 1, which is placed on the circumference of the grinding cylinder. The support device 10a of direction support constraint and the support device 10b that is located on the transmission shaft 13 constitute;

Embodiment 3

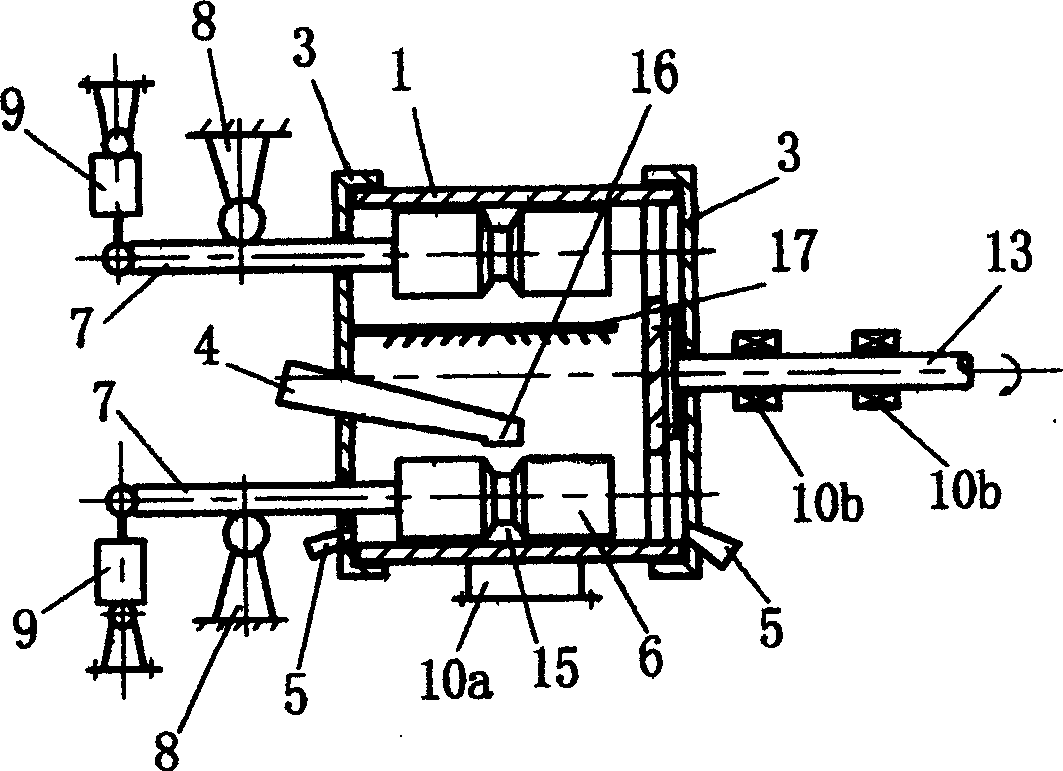

[0022] Embodiment 3, see Fig. 4.

[0023] In this example, the pressurizing mechanism 9 is set on the roller shaft section outside the hinge support 8; the middle part of the grinding roller 6 is provided with a groove 15, and the feeding port 16 of the feeding device 4 is located at the The middle part of the roller 6 corresponds to the groove 15; in addition, a two-way feeder 17 is provided in the grinding cylinder to allow the material to flow from the middle of the grinding roller 6 to both ends, and it is connected to the end cover, and the two-way feeder 17 is set The component 18 that makes the material flow from the middle of the grinding roller to both ends, during the implementation process, the scraper in the grinding cylinder can be combined with the bidirectional feeding device 17, or can be set separately from the bidirectional feeding device 17; The end caps at both ends of the barrel are provided with a discharge port 5, and the others are the same as in Embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com