Interferometric method using partial compensation lens to realize nno-spherical surface shape

A technology of interferometric measurement and compensation lens, which is applied in the field of interferometric measurement, can solve the problems of stray light interference, large loss of return light wave, poor quality, etc., and achieve the effect of high precision and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

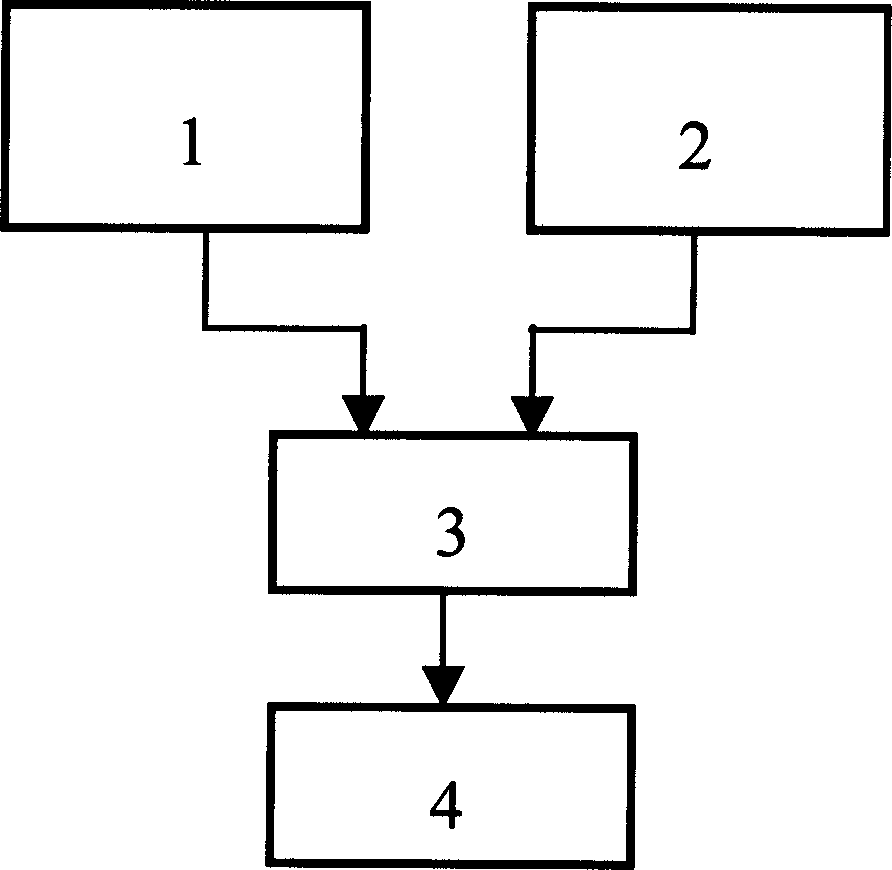

[0019] This method is implemented in the following steps:

[0020] Step 1: Calculate the virtual interference fringes from the optical path of the interferometer, the standard data of the measured aspheric surface and the partially compensated lens structure;

[0021] Step 2: Digital moiré synthesis with the actual interference fringes obtained by the actual interferometer to realize the subtraction of the measured wave front and the theoretical wave front, the systematic error in the interferometer is offset, and the moiré fringes are the interference between the actual aspheric surface and the standard aspheric surface stripe;

[0022] Step 3: Then process the measured aspheric surface shape error by digital phase shifting.

[0023] The invention has the advantage that: the surface shape of the measured aspheric surface is not limited to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com