High building glass curtain wall cleaner system

A glass curtain wall and cleaning machine technology, applied in the direction of cleaning machinery, cleaning carpets, cleaning floors, etc., can solve the problems of high cost, low cleaning efficiency, and inability to cross window frames, etc., to achieve reliable cleaning methods, improve water utilization, and improve The effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

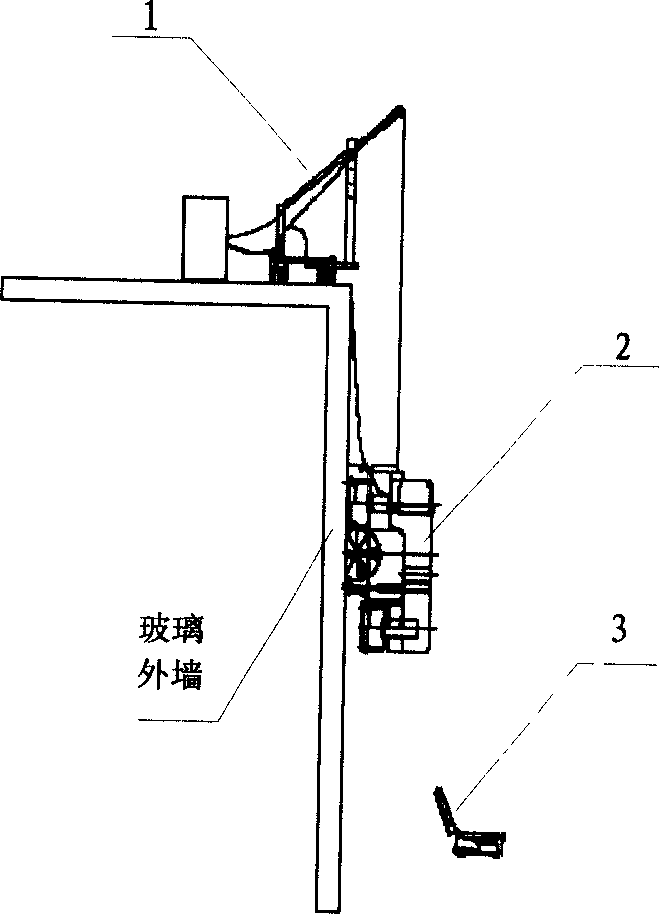

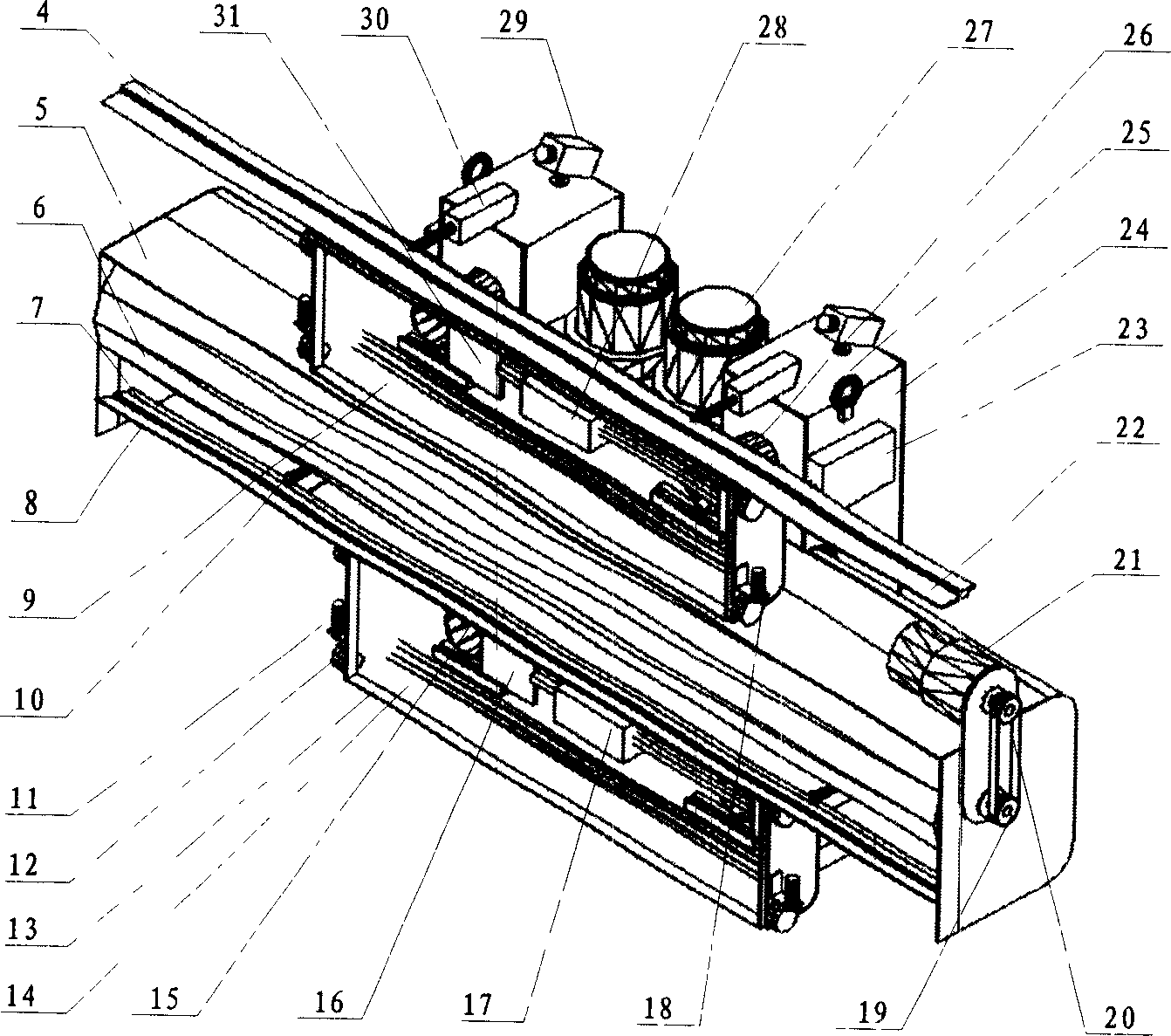

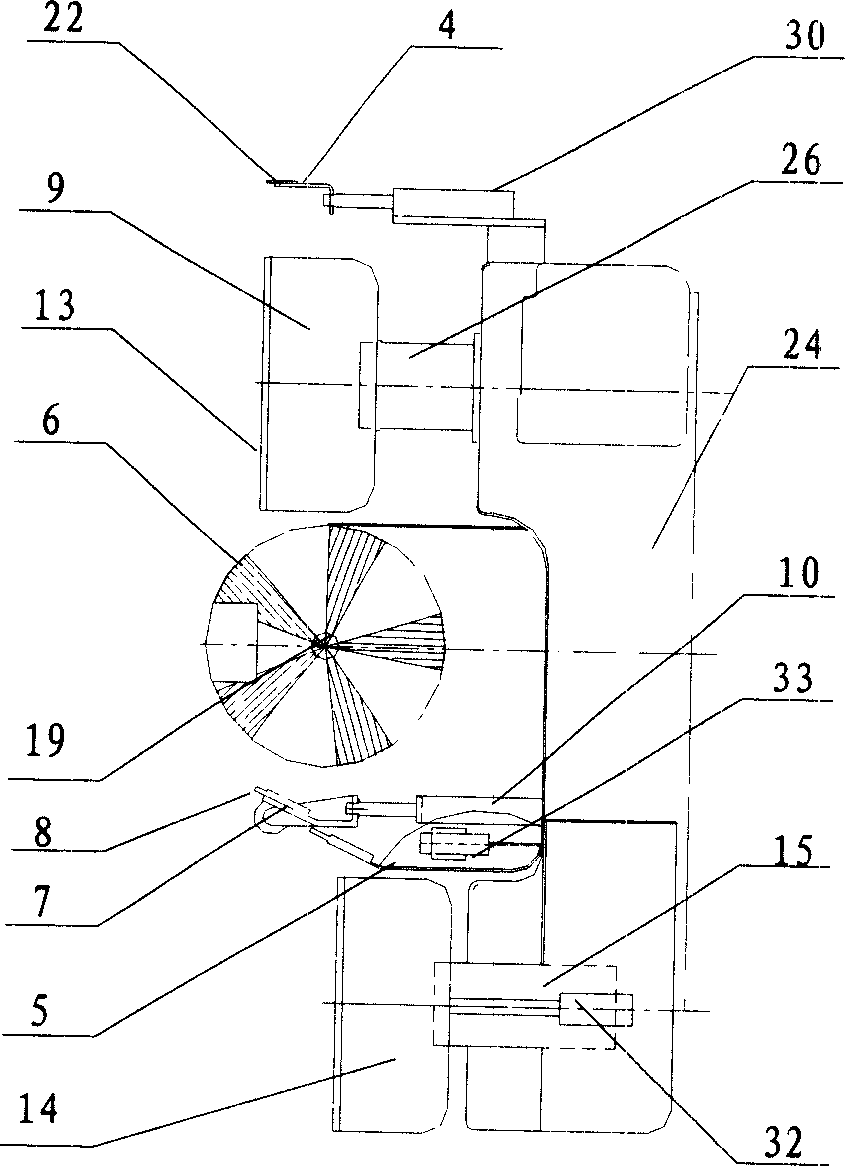

[0031] Cleaning machine system structural composition of the present invention is as figure 1 As shown, it mainly includes a roof safety device 1, a washing machine body 2, a downstairs portable monitoring device 3 and an electrical control device. The structure of washing machine body 2 is as figure 2 , image 3 , Figure 4 As shown, the washing machine body 2 is under the traction of the winch in the roof safety system 1, relies on the rubber strip 13 of the sealing mechanism, the side follower roller 12, and utilizes the upper suction cup 9 of the double suction cup negative pressure adsorption mechanism and its pneumatic components 23 1, the lower suction cup 14 and its pneumatic components 32 are simultaneously or alternately adsorbed on the glass wall, relying on its own gravity to move up and down to realize functions such as wall c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com