Tin cream coating assistant apparatus

An auxiliary equipment and solder paste technology, which is applied in the direction of electrical components, printed circuit manufacturing, printed circuit, etc., can solve problems such as high failure rate, waste of solder paste, and reduced operating efficiency, and achieve the effect of reducing the failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

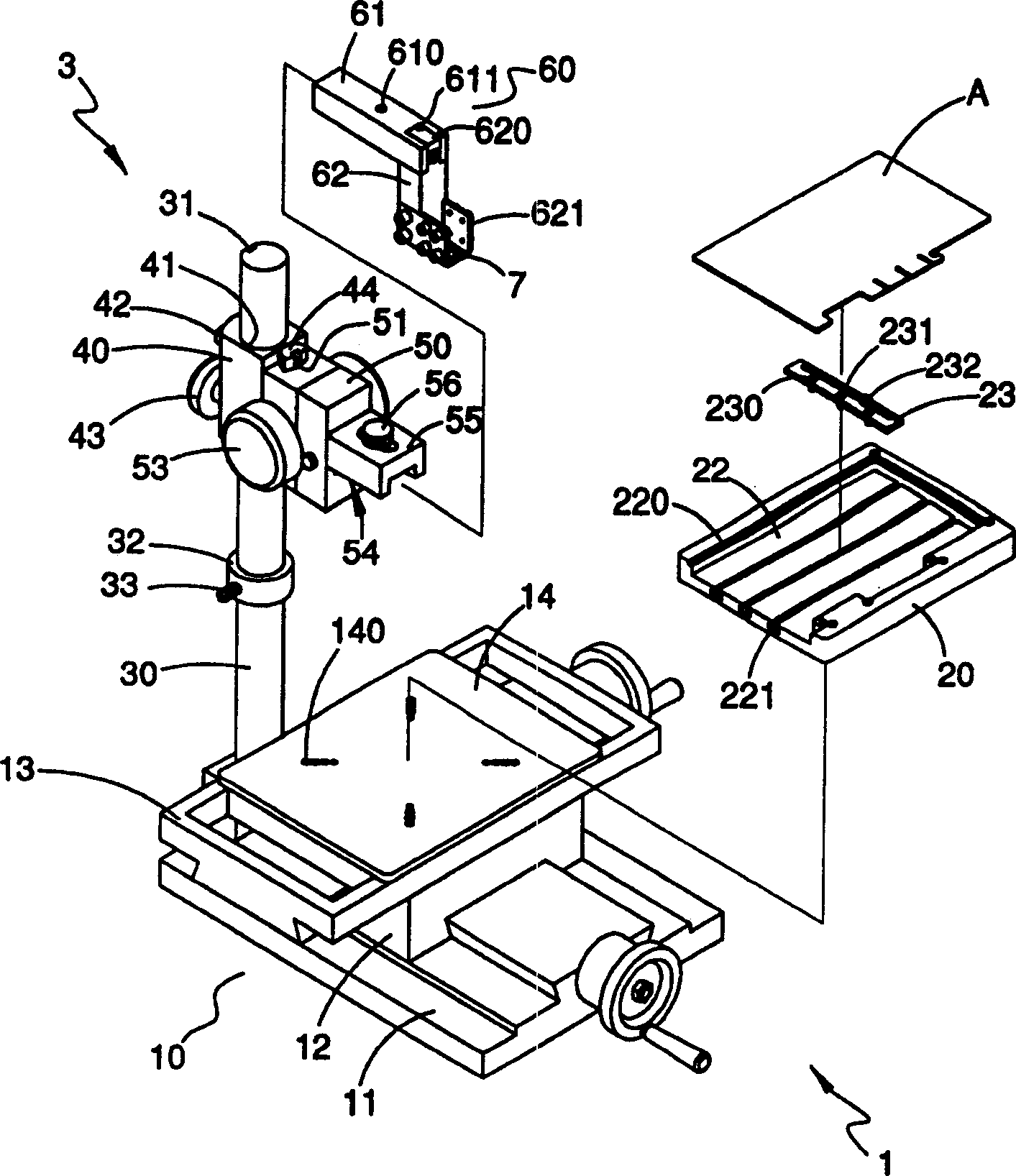

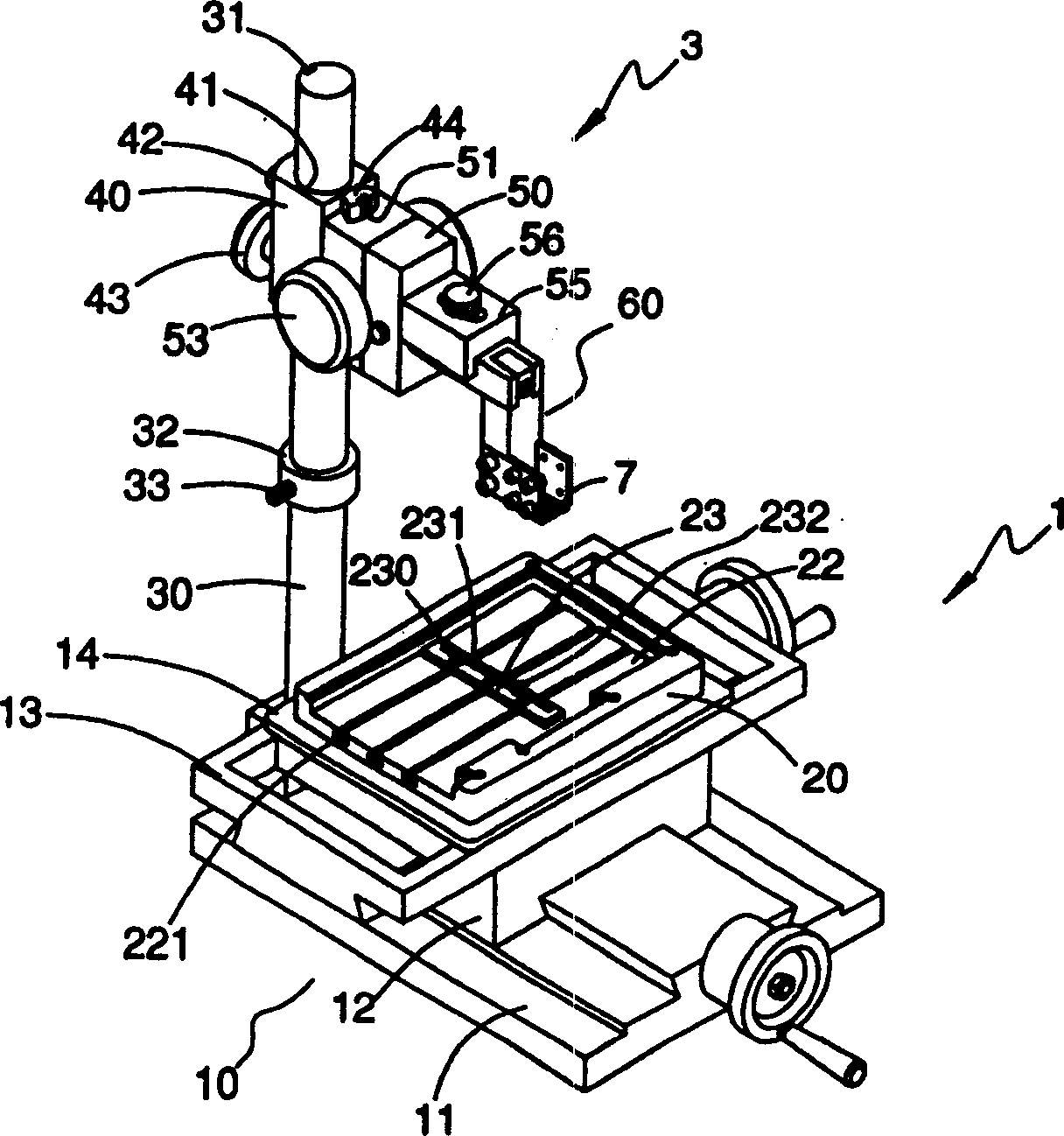

[0019] exist figure 1 In the preferred embodiment shown, it shows the three-dimensional appearance of a solder paste coating auxiliary equipment, which generally includes:

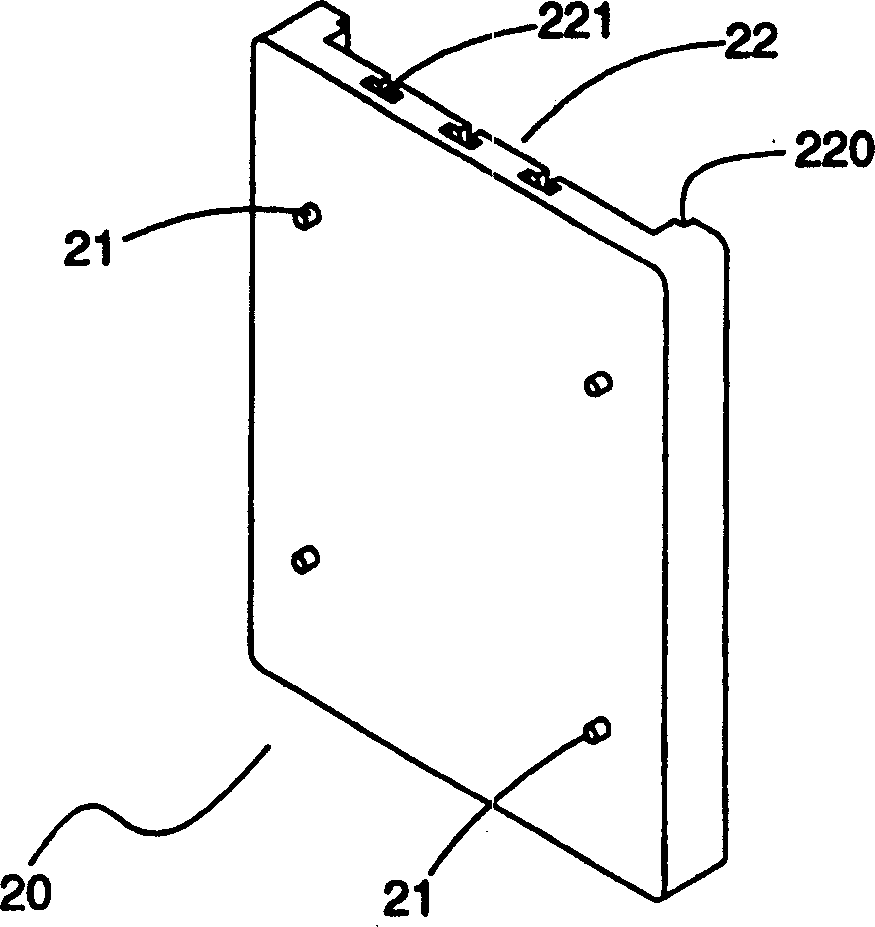

[0020] A moving device 1 is provided to receive a work object A and adjust the two-dimensional position of the work object A. Wherein, the workpiece A is a circuit board in this embodiment.

[0021] A lifting device 3 is located on one side of the moving device 1 .

[0022] A tin planting device 60 is arranged on the lifting device 3 and its height position can be controlled by the lifting device 3 , and the tin planting device 60 is also provided with a tin planting plate 7 for extending above the workpiece A. Wherein, the tin planting plate 7 is similar to Figure 7 The bottom plate of the shown tin planting plate also has a plurality of through tin planting holes and multiple wall plates.

[0023] Since the moving device 1 can be used to move the tin-planting area where the workpiece A is to be coat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com