Drum washing machine

A drum-type washing machine, washing machine technology, applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of position deviation, water leakage, difficulty in improving strength, etc., achieve watertight state to maintain stability, not easy to position deviation, prevent deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] An embodiment of the present invention will be described below with reference to the accompanying drawings. It should be noted that the general technical idea of the present invention is not limited by this embodiment.

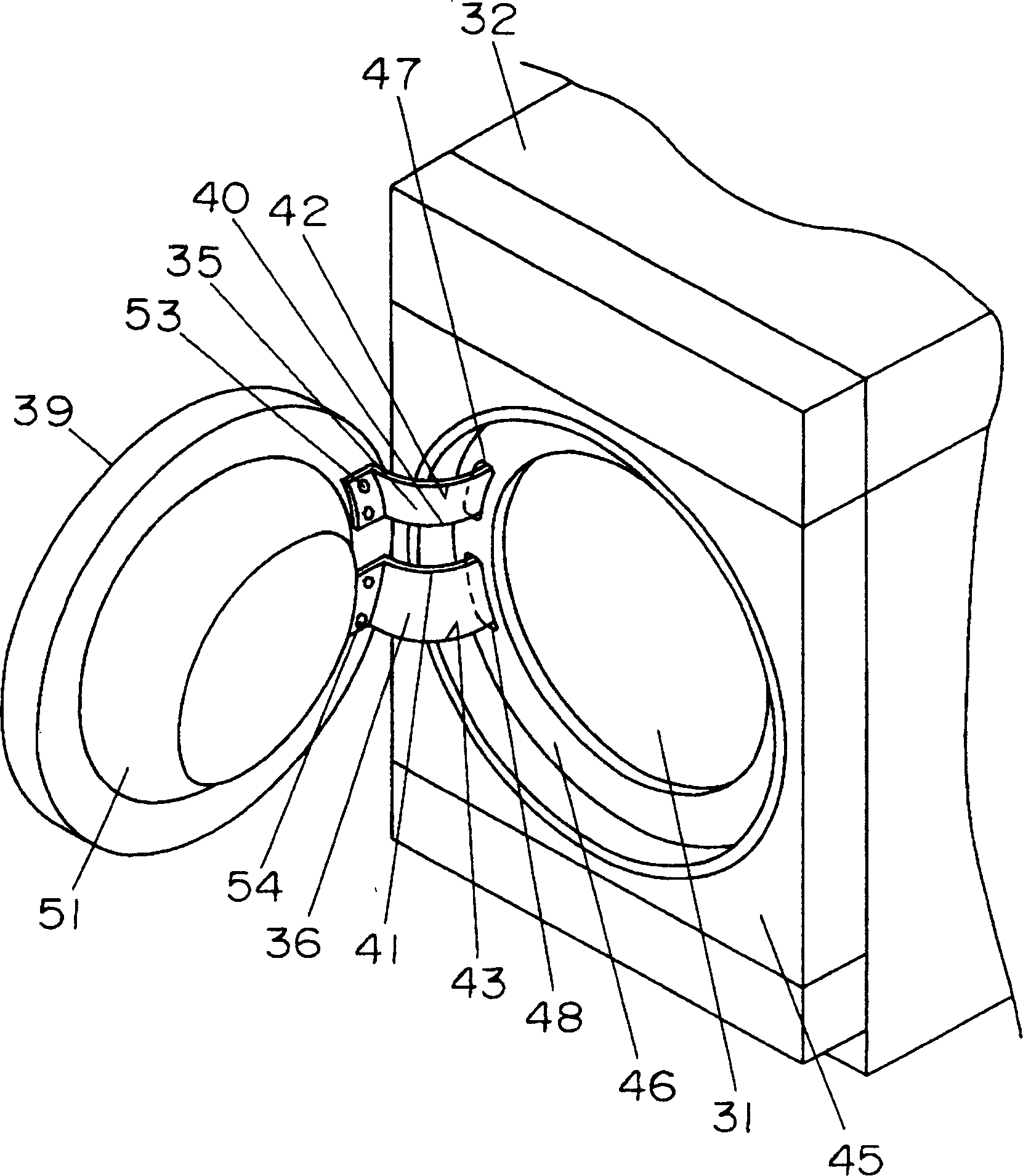

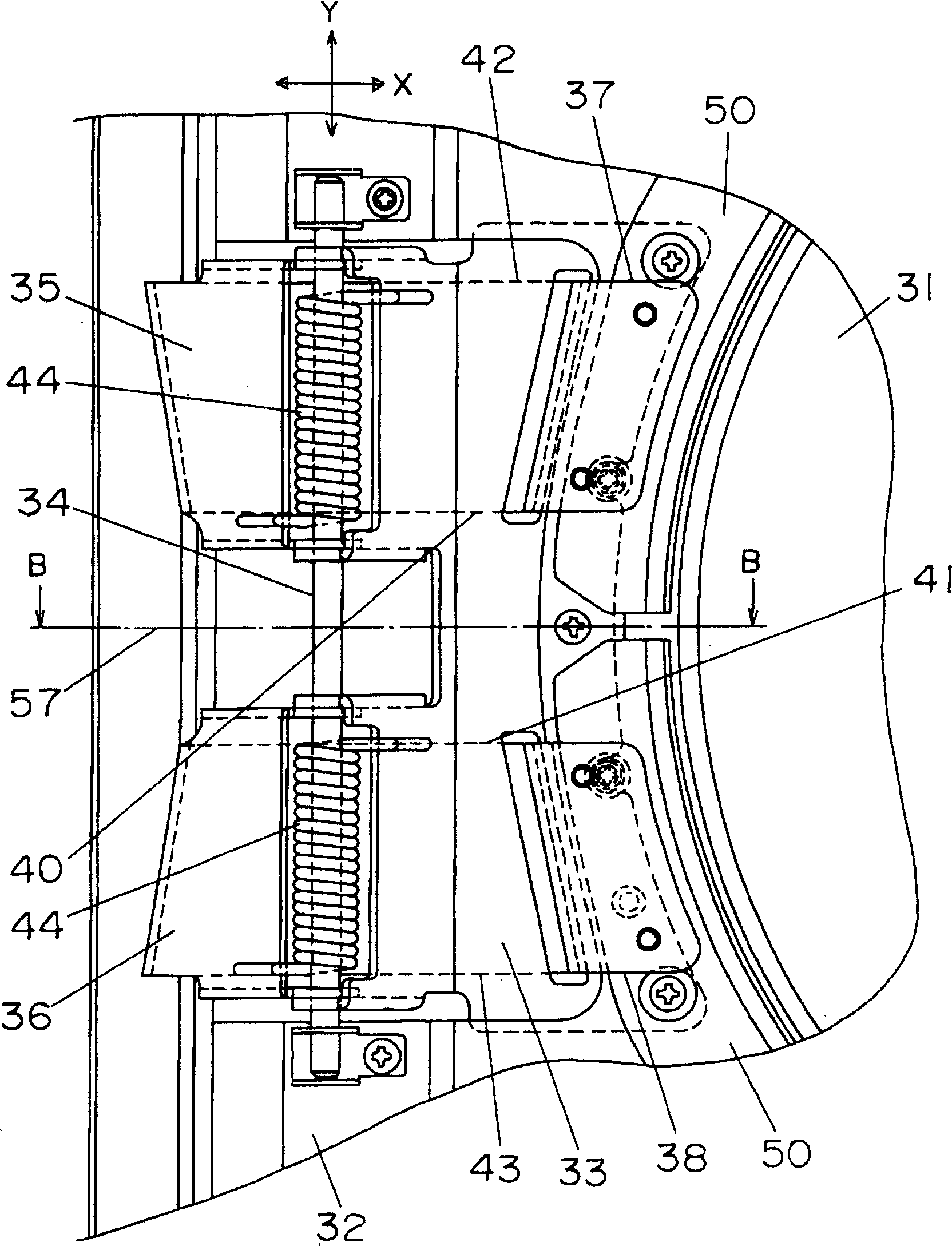

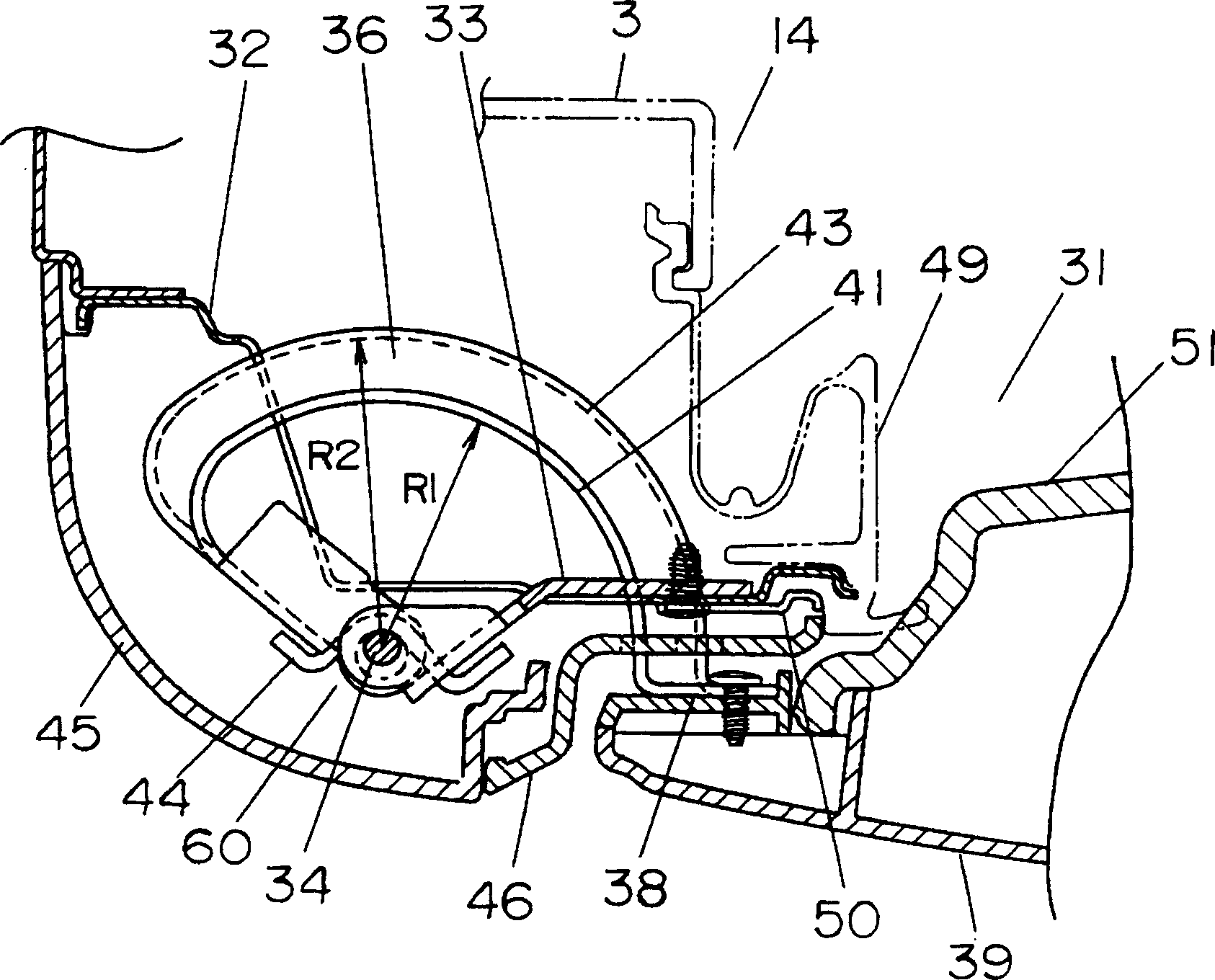

[0028] figure 1 It is an oblique view of the drum-type washing machine in an open state of the cover in one embodiment of the present invention, figure 2 is a front view showing the main structure around the coupling parts, image 3 when the cover is closed figure 2 The sectional view of the B-B line in, Figure 4 when the cover is open figure 2 The sectional view of the B-B line in, Figure 5 A longitudinal section view of the entire body. in addition, Figure 5 The same constituent parts as those in the conventional device are assigned the same symbols, and repeated description thereof will be omitted. In addition, since a series of operations such as washing, rinsing, and dehydration are the same as those in the conventional device, des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com