Door lock switch

A door lock switch and switch technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of short locking and unlocking time and long unlocking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

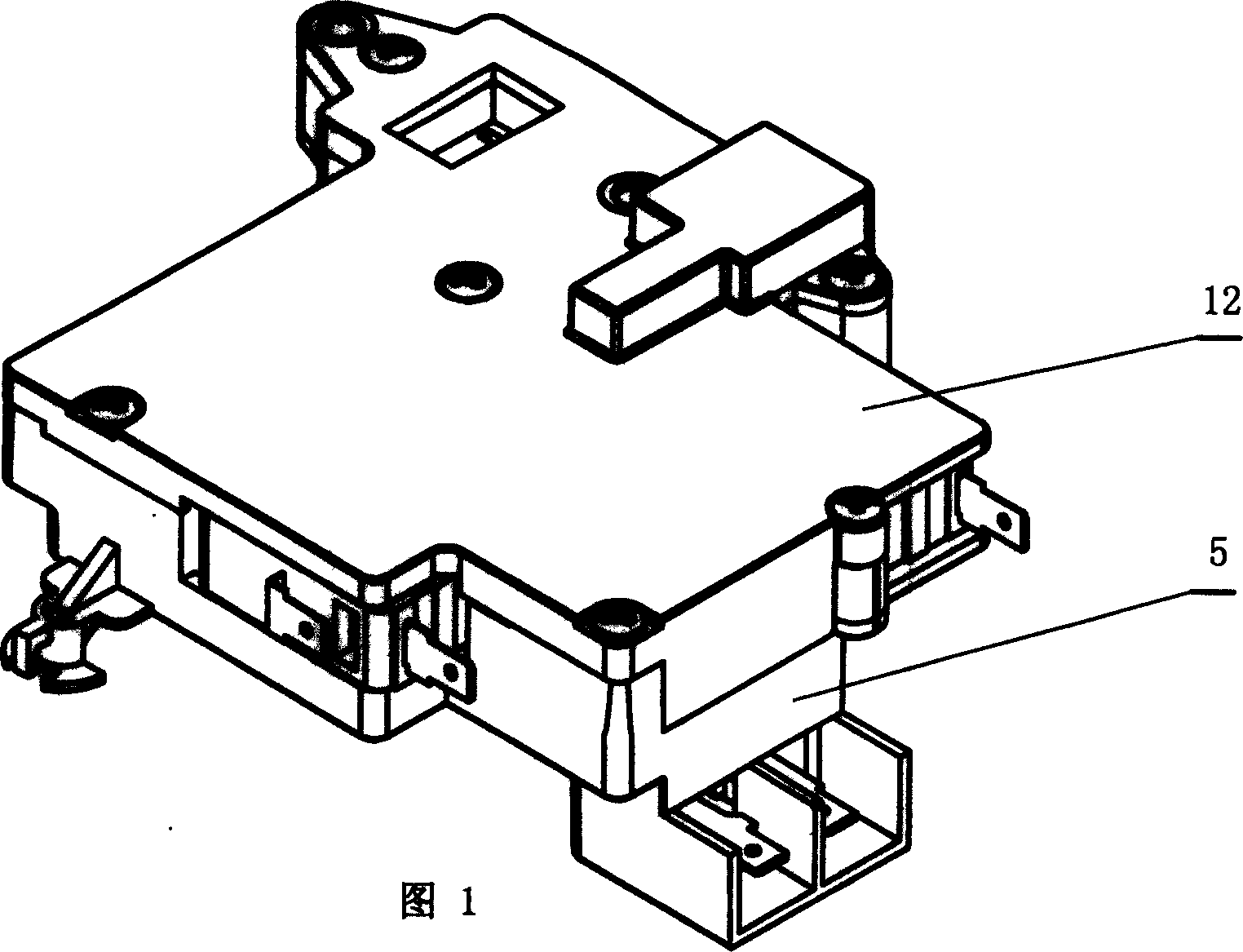

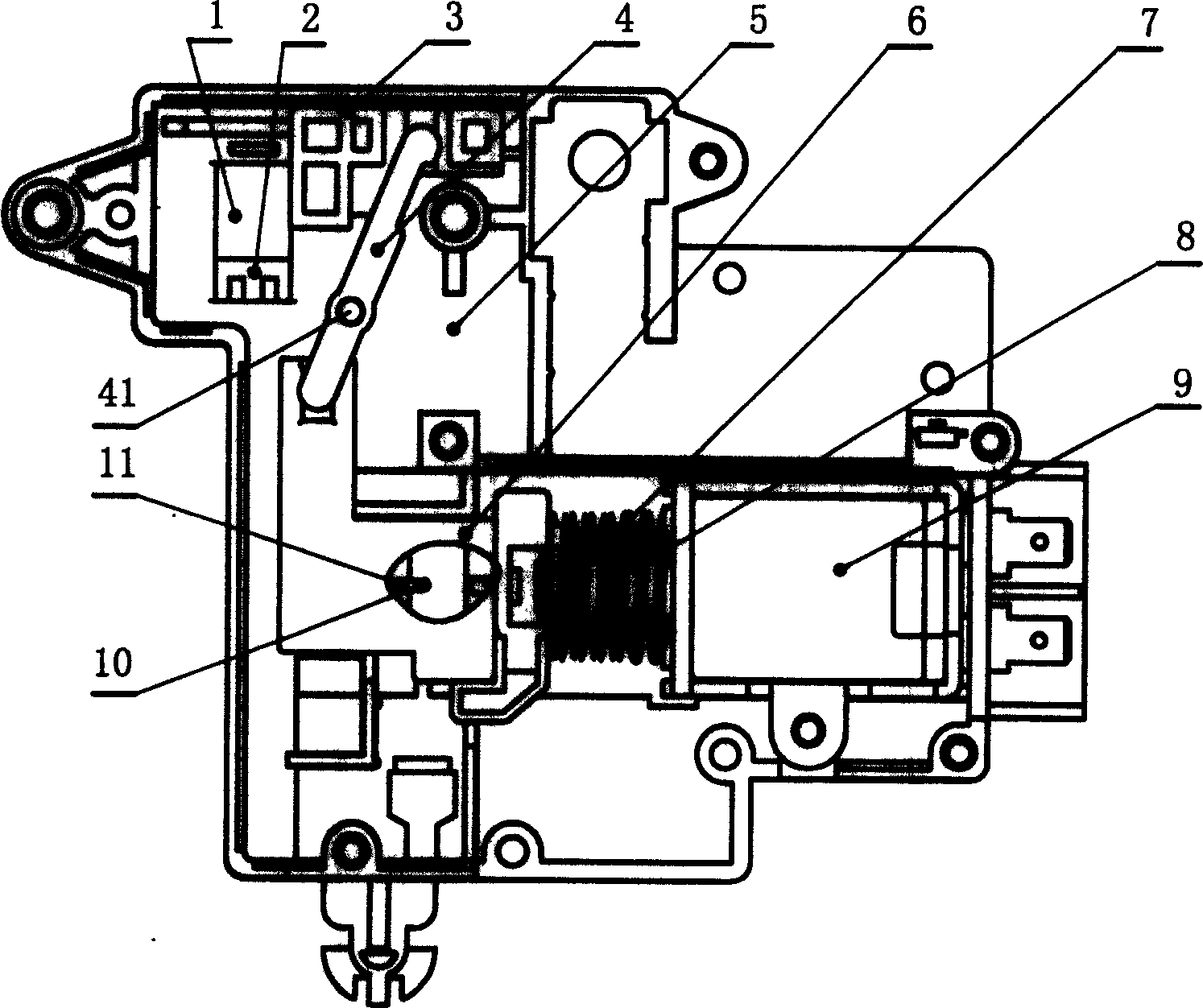

[0030] This example door lock switch, see Figure 1, figure 2, with a base body 5 and a cover plate 12 with a hook hole 1, a buckle edge 2 is provided under the hook hole, an electromagnetic coil 9 and an operating slide plate 6 are arranged inside the base body 5, an iron core 8 is connected to the operating slide plate 6, and a spring 7 is sheathed on the periphery of the base body 5 Located between the electromagnetic coil and the operating slide plate, the inner surface of the operating slide plate 6 is provided with a "positioning / resetting" guide groove 11, and a positioning pin 10 is provided, the fixed end 101 of which is connected to the base body 5, and the other end is located in the guide groove 11, and the base body 5 is provided with a There is a slider 3 located in the inner direction area of the upper part of the hook hole 1, and the middle part of the lever 4 is pivotably sleeved on the fulcrum pin 41, and the inner protrusion of one end of the lever 4 is embe...

Embodiment 2

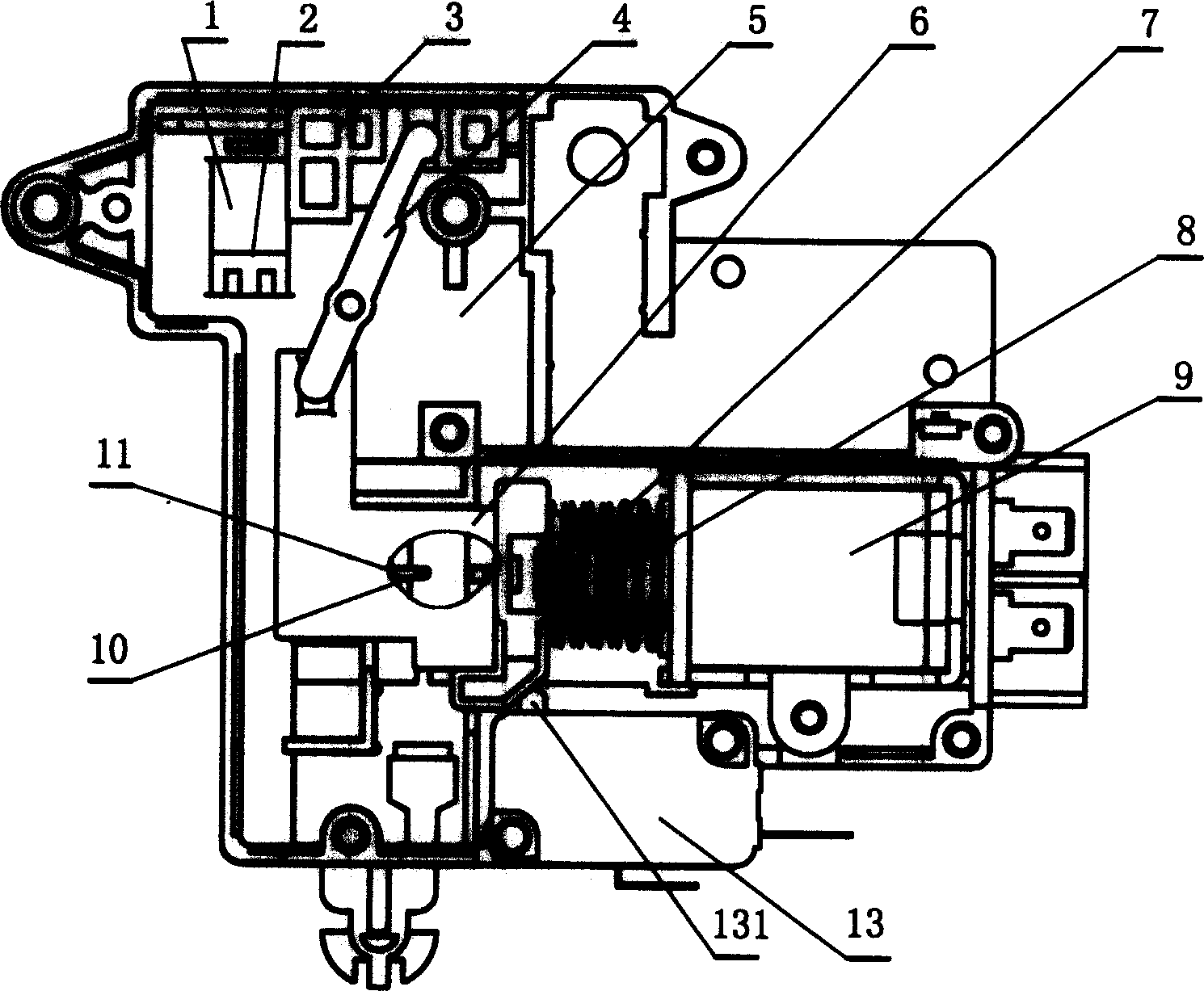

[0033] This example door lock opening, see image 3 , The base body 5 is provided with a microswitch I 13 whose inner side is provided with a contact 131, and one end of the operation slide plate 6 corresponding to the contact 131 is provided with a slope. Other structures are the same as the above example.

[0034] When the electromagnetic coil energized operation slide plate was sucked and positioned, the microswitch I 13 contacts 131 retracted under the pressure of its inclined plane, which can generate a locking signal.

Embodiment 3

[0036] For this example door lock switch, see Figure 4 , Figure 9, Figure 10 , the base body 5 is provided with a button 17, a micro switch II 18 and a leaf spring 19. One end of the leaf spring 19 is a fixed end 192 connected to the base body 5, and the other end is connected with a bevel plate 191. One end of the button 17 has a convex post 171 located on the base body 5 The through hole protrudes outward from the back of the base body 5. The other end of the button 17 is the abutting end 172 against the inclined plate 191. The side of the micro switch II 18 and the leaf spring 19 is provided with a contact 181. The button 17 The inner surface is topped with a spring 21 corresponding to the boss 171 . The base body 5 is provided with a manual unlocking plate 16 , the inner end of which is provided with a slot hole 161 to cover the positioning pin 10 . Other structures are the same as in Example 1.

[0037] After the door is closed, push the button 17 to move inward thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com