Ginsenoside Compound-K preparing method

A technology of ginsenosides and total ginsenosides, which is applied in the field of pharmacy, can solve the problems of low CompoundK content and inability to be separated, and achieve the effects of convenient extraction and separation, benefit to the pharmaceutical or health care product industry, and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

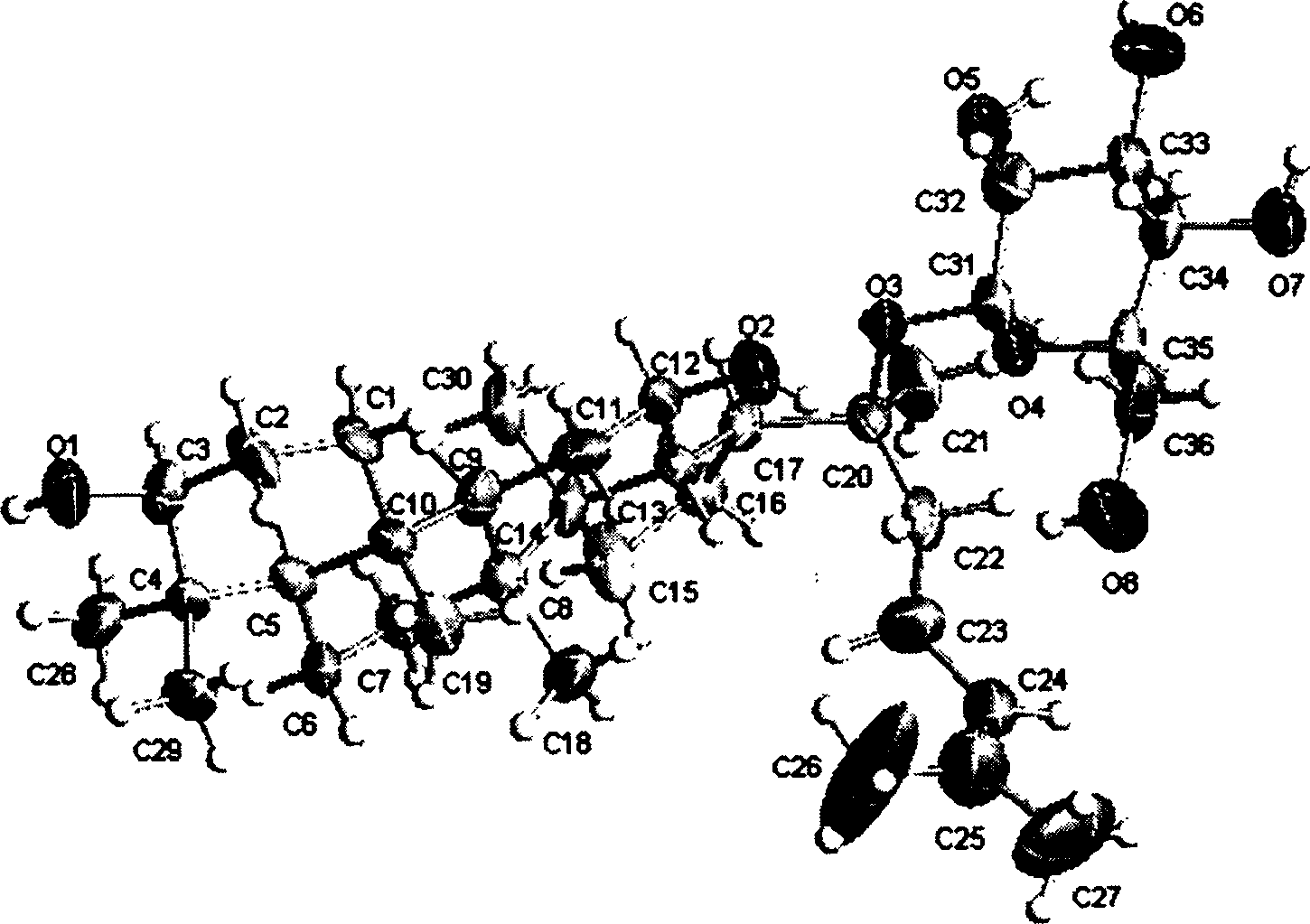

Method used

Image

Examples

Embodiment 1

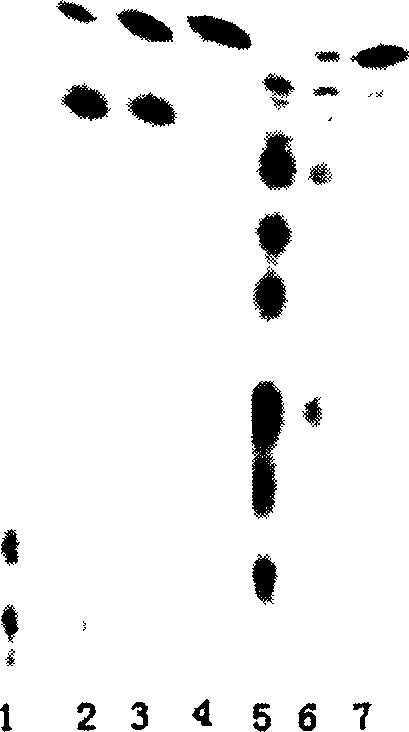

[0069] Collect soil samples, dry them, pour them into a pre-sterilized mortar, grind them finely, spread them on white paper irradiated with ultraviolet light, pop them onto potato plates, and cultivate them at 28°C. Pick a single colony of mold and culture them on the slant medium for fermentation. Strain screening.

Embodiment 2

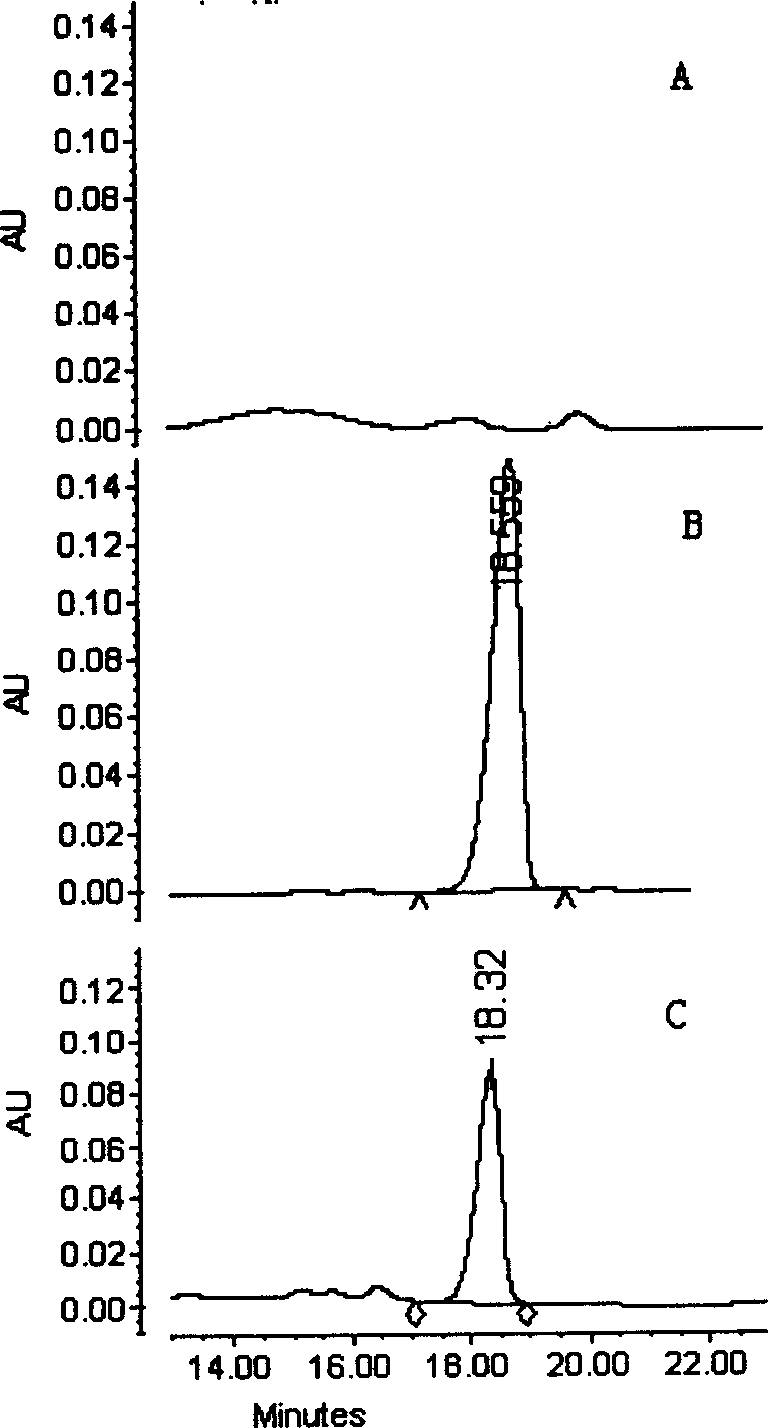

[0071] Aspergillus niger was grown on Chua's medium (28°C, 7 days). After the spores were plump, they were inserted into the seed medium containing glucose-corn steep liquor-ammonium sulfate, and rotated at 25-35°C and 200rpm. When the mycelium grows luxuriantly, the seed culture solution is put into the fermenter at a ratio of 5-10%, at 26-28°C, the speed is increased from 200rpm to 800rpm, and the dissolved oxygen is 20-40%, and cultivated for 60-72 hours. Feed 2% of total saponins in stems and leaves of Panax notoginseng, and continue culturing for 40-56 hours to transform ginsenosides. According to HPLC analysis, the fermentation conversion rate is 12%, the final extraction and separation yield is 5.25%, and the Compound K content is above 97%.

Embodiment 3

[0073] Aspergillus niger (Aspegillus niger) spore suspension was inoculated into a 5L shake flask containing 1L glucose-corn steep liquor-ammonium sulfate medium, pH 5.0, cultivated on a rotary shaker at 30°C at 180r.p.m for 72h, 1% cultivated total ginsenosides Feeding, conversion 48h. Alcohol extraction of the fermentation conversion solution, filtration, vacuum evaporation, methanol dissolution, HPLC analysis, the conversion rate is 8%, the final extraction and separation yield is 5%, and the Compound K content is more than 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com