Device for betelnut sheet entering into mould

A technology of betel nut slices and electric control box, which is applied in the directions of transportation and packaging, conveyors, food processing, etc., can solve the problems of low production efficiency, many employees, and poor sanitary conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

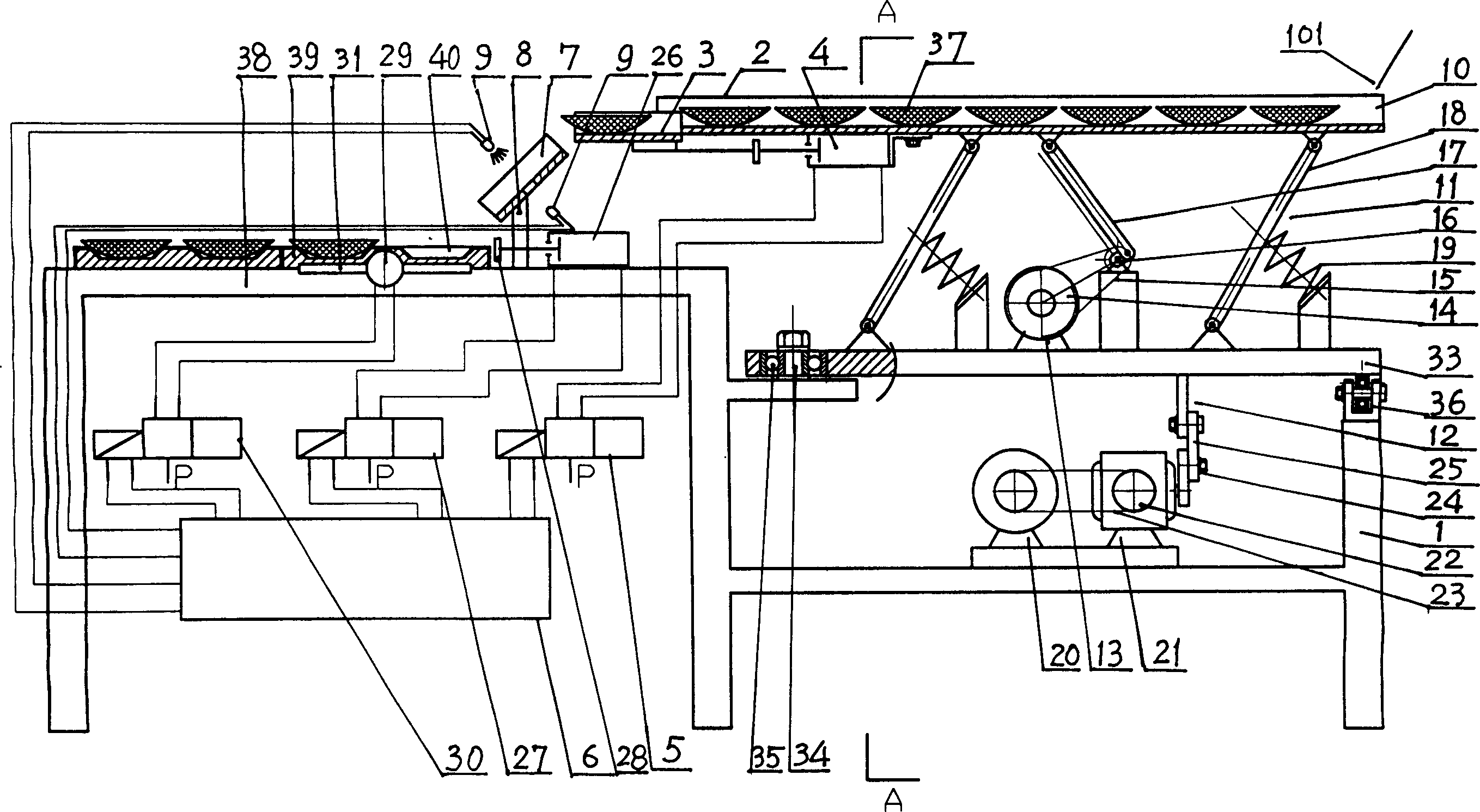

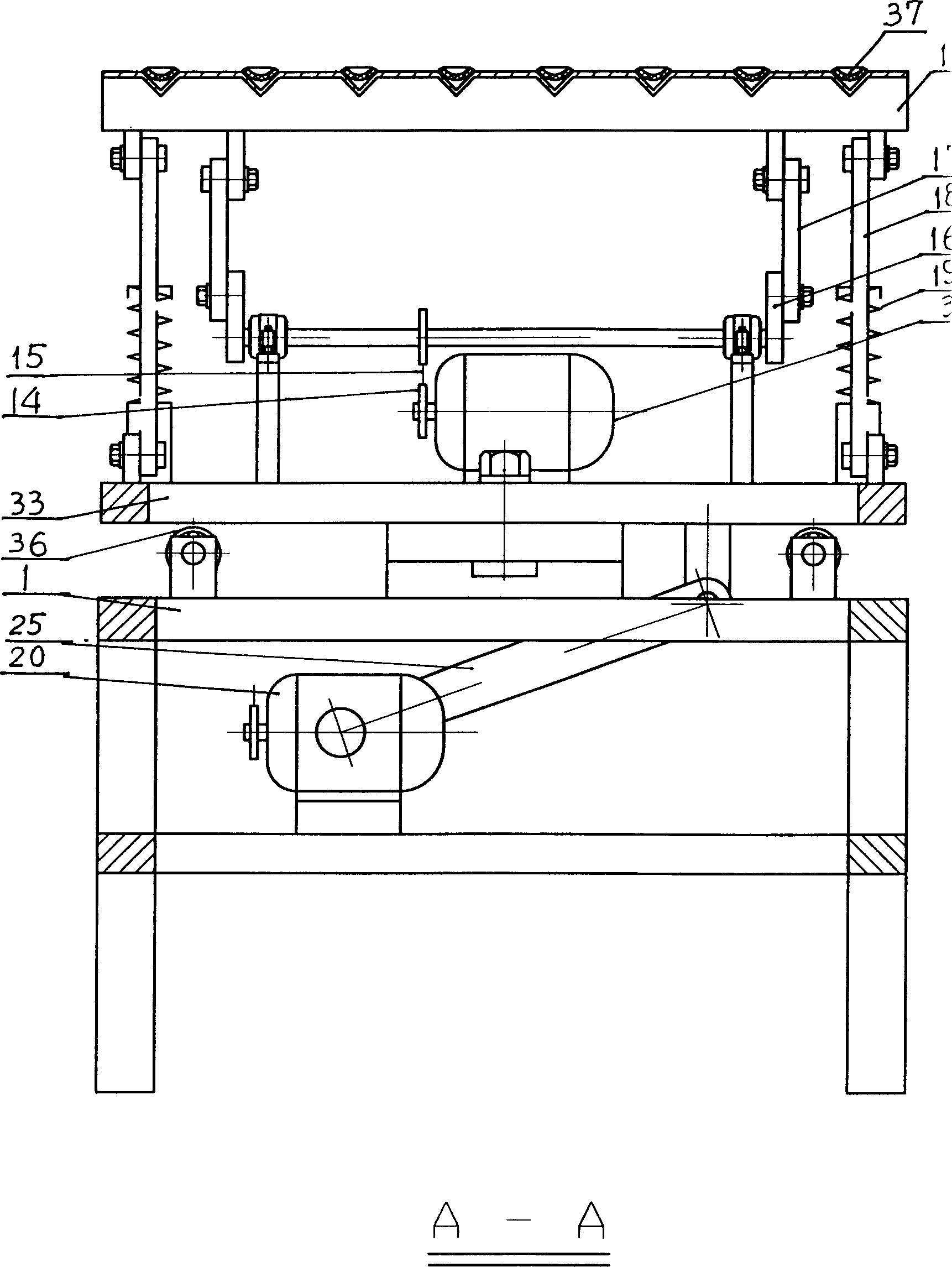

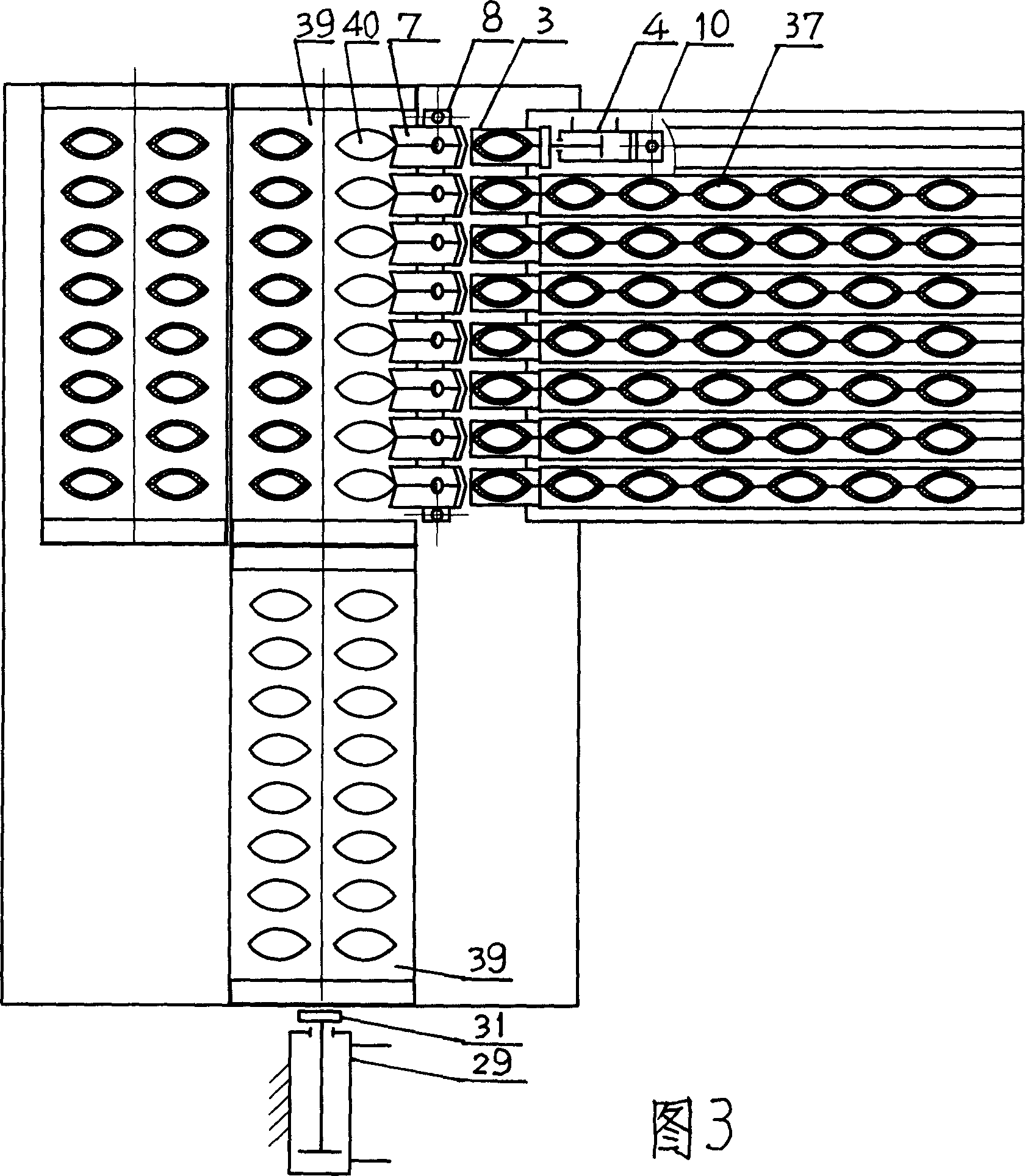

[0017] see figure 1 , figure 2 , Fig. 3, this betel nut sheet mold-entry device, on the base 33 that is movably connected with frame 1, vibrating conveying mechanism 11 is installed, and the top of vibrating conveying mechanism 11 is equipped with conveying trough body 10, and the cross section of trough body is V shape, a plurality of movable pallets 3 are installed below the end 2 of the conveying tank body 10, the movable pallets 3 are connected and driven by the cylinder 4 of the driving mechanism, and the cylinder 4 is fixedly connected to the bottom of the conveying tank body, and the driving mechanism also includes There is a solenoid valve 5, and the inlet and outlet pipes of the cylinder 4 are connected to the solenoid valve 5 and controlled by the solenoid valve 5. The solenoid valve 5 is electrically connected to the electric control box 6 and is controlled by the electric control box 6. A plurality of mold chutes 7, a plurality of mold chutes 7 are installed and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com