Overturning stamp and overturning method

A seal and guide frame technology, applied in printing, stamping and other directions, can solve problems such as inconvenience in use, easy deformation of atomic stamp molds, etc., and achieve the effect of avoiding messy ink and novel structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

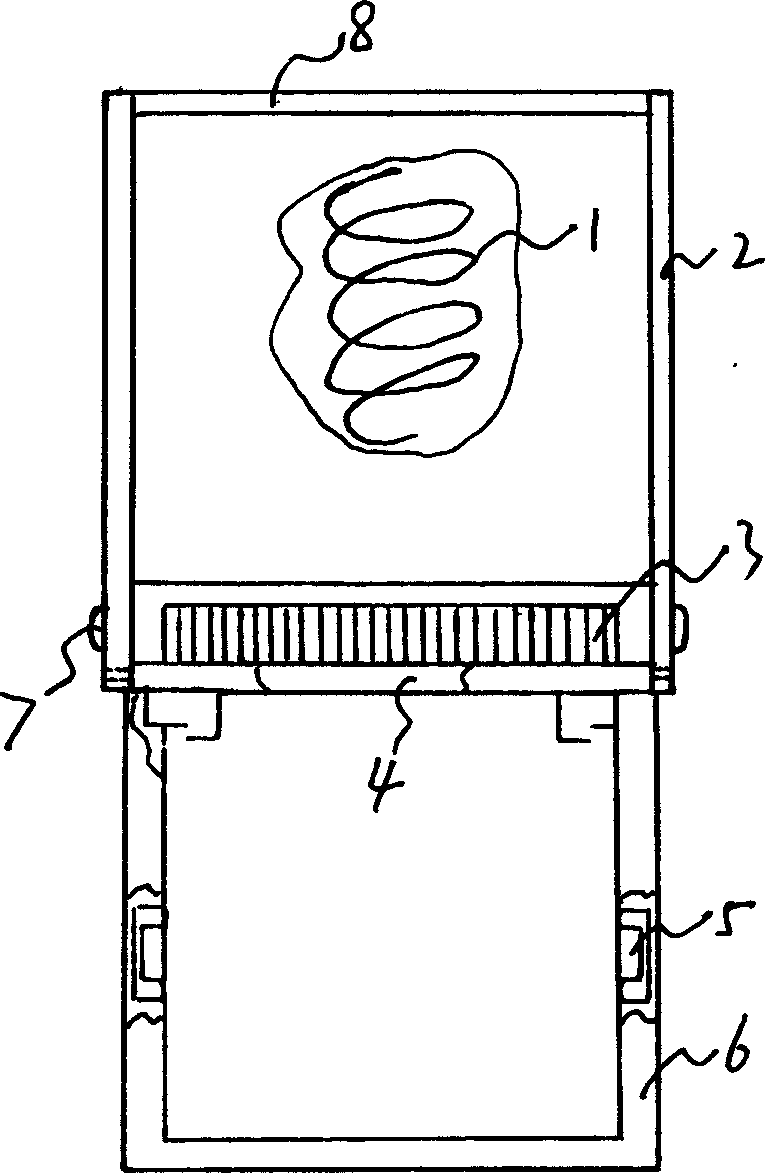

[0009] Embodiment 1: with reference to attached figure 1 . Flip the stamp, the guide frame 6 is molded by injection molding and is located in the stamp shell 2, and the upper end of the stamp shell 2 is provided with a transparent inlaid cover 8 for keeping and observing the stamp pattern. A compressed return spring 1 is interposed between the upper end of the guide frame and the seal case. Design spring self-locking structure 7 between seal shell and guide frame, spring self-locking structure 7 is prior art, do not narrate here. The drawer-type ink cartridge 3 adopts mold injection molding, the drawer-type ink cartridge 3 is located in the drawer guide hole on the upper part of the guide frame and can be pulled out and inserted, the turning shaft 4 is located at the lower part of the stamp shell and can be turned over, and the turning stamp body 4 is turned over The angle is 180 degrees. Turnover seal body 4 is made of turning body and seal, and seal adopts plastics or nyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flip angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com