Testing method for on-line testing transformer internal insulating hidden trouble

A technology of internal insulation and testing methods, applied in the direction of measuring electrical variables, instruments, measuring electricity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

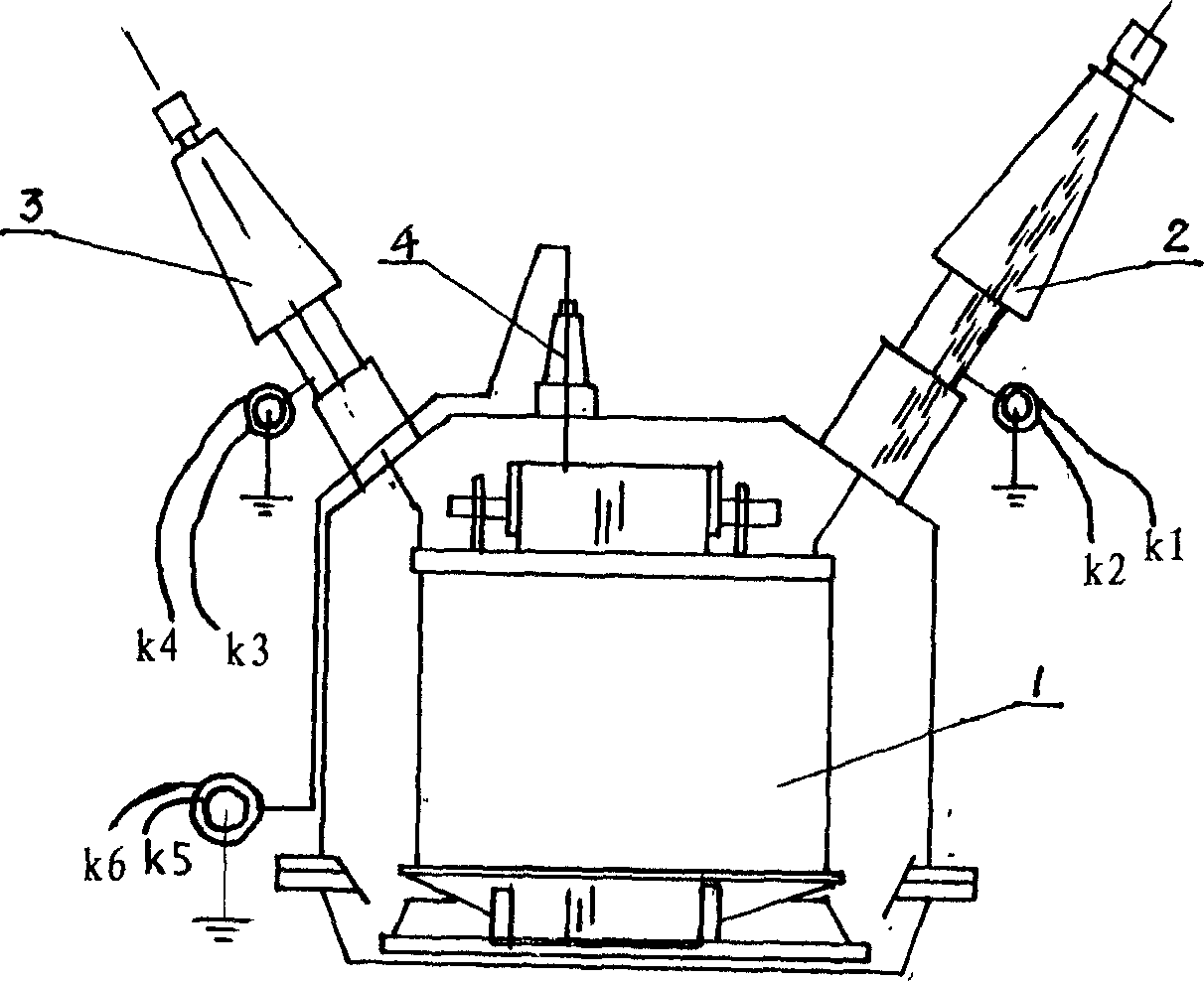

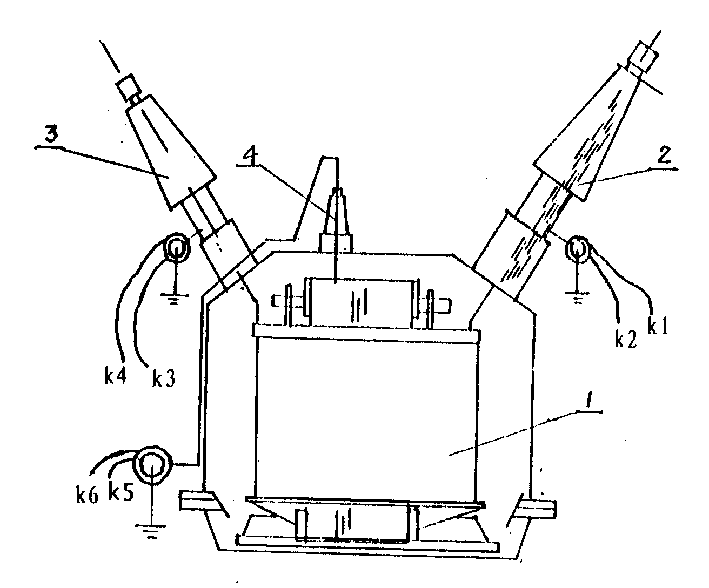

[0013] As shown in the accompanying drawing, a new type of testing method for on-line detection of hidden dangers in the transformer’s internal insulation is to use high and medium voltage bushings 2, neutral point bushings 3, and iron core grounding sleeves from transformer 1 during the operation of the transformer. A sensor K that can respond to transient signals is used at the ports of the pipe 4 1 、K 2 、K 3 、K 4 、K 5 、K 6 To collect non-power frequency signals, and according to the collected signal waveform, amplitude, and time changes, in conjunction with other parameter changes, to analyze and judge the degree of damage to the main and cluster insulation inside the transformer.

[0014] In terms of signal acquisition, capacitive voltage division method, resistive voltage division method or electromagnetic induction method can be used to collect non power frequency signal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com