Thread-clamping and thread-loosing apparatus for straight-bar machines

A technique for thread pressing and thread removal, applied in textile and papermaking, weft knitting, knitting, etc., can solve the problems of affecting the opening and unhooking of the latch, cumbersome replacement of sinkers, inconvenient installation and disassembly, etc., and achieves quality reliability. The effect of improving, good weaving quality and quick installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention and its advantages will be further described below in conjunction with the accompanying drawings.

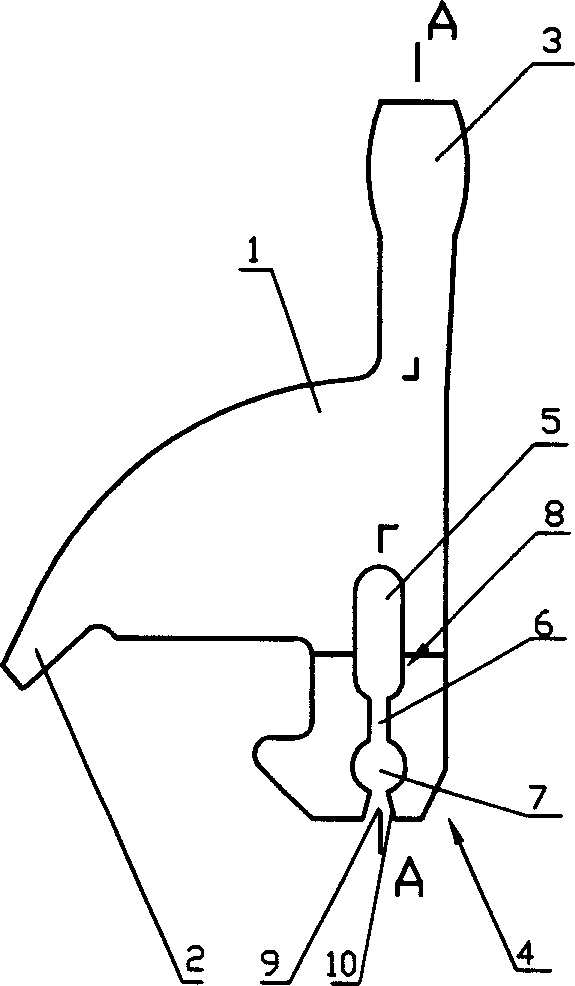

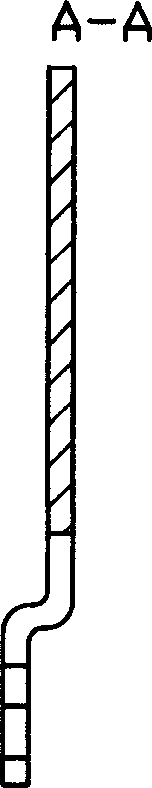

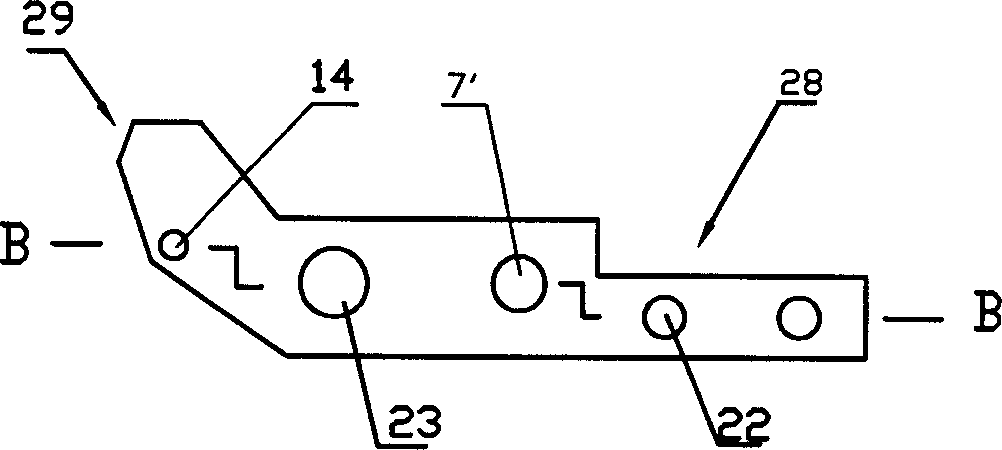

[0018] figure 1 , figure 2 It is the sinker device designed in this embodiment. It is stamped by 0.6mm 65Mn steel strip. After heat treatment, the surface hardness is HRC 52-58. There is a half-arched plane base 1, and its contraction end extends out to the lower side. A crimping part 2 is provided, and a needle bell part 3 extends from the upper side of the high end of the arch, and the lower side of the high end of the arch extends toward the left side of the base 1 through two consecutive bends at 90° angles to extend downwards to a mounting part 4 , the mounting part 4 is parallel to the base part 1 and the crimping part 2, and the distance between the two planes is 0.45 mm. A positioning hole 7 is provided on the mounting part 4 with a diameter of φ195-0.05 mm. The upper end of the positioning hole 7 is provided with a The long slotted hole 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com