Radial drilling machine capable of conducting boring processing

A radial drilling machine and boring technology, which is used in boring/drilling devices, boring/drilling, metal processing equipment, etc. Reasonable structure, improve labor productivity, reduce product cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

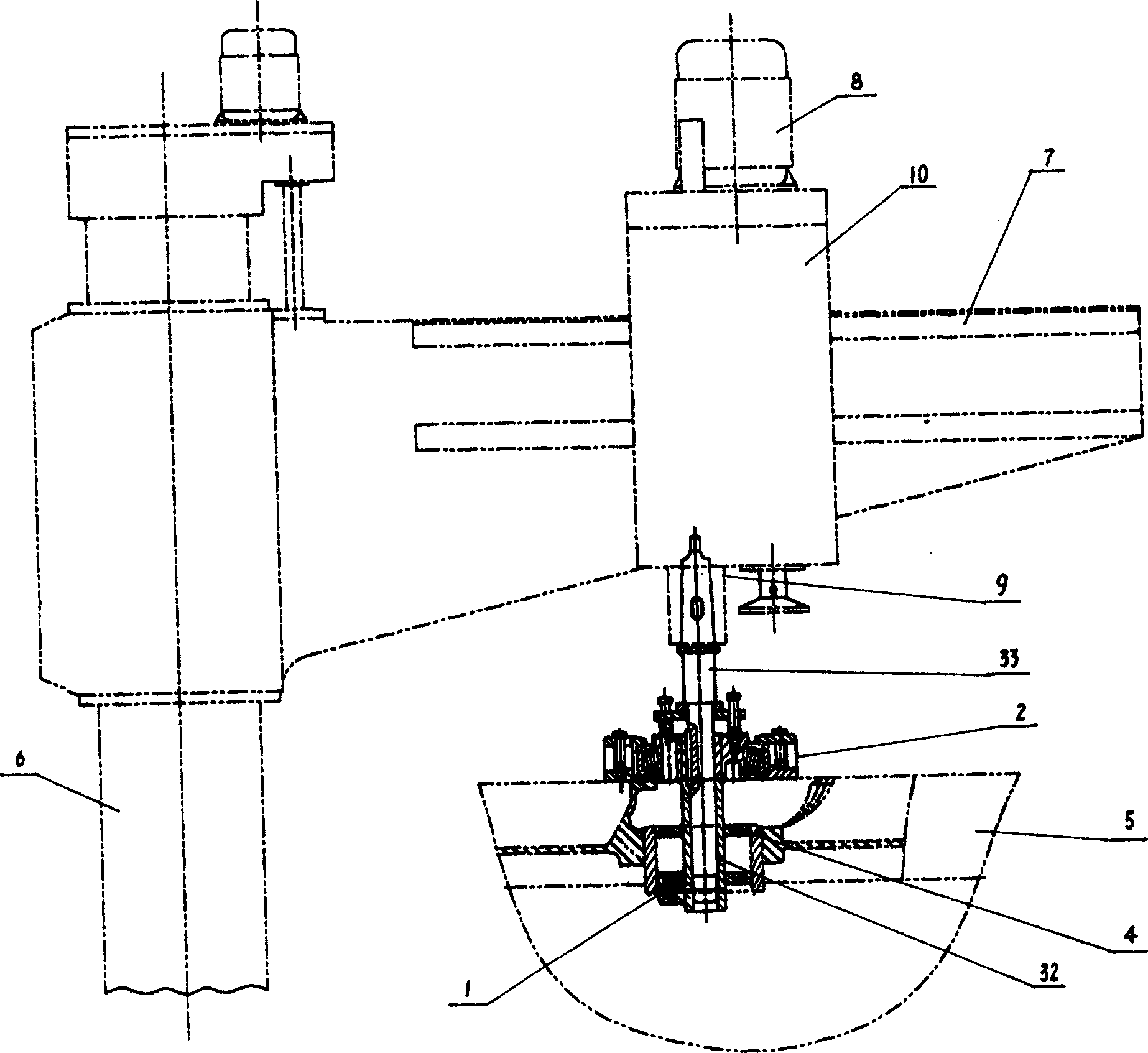

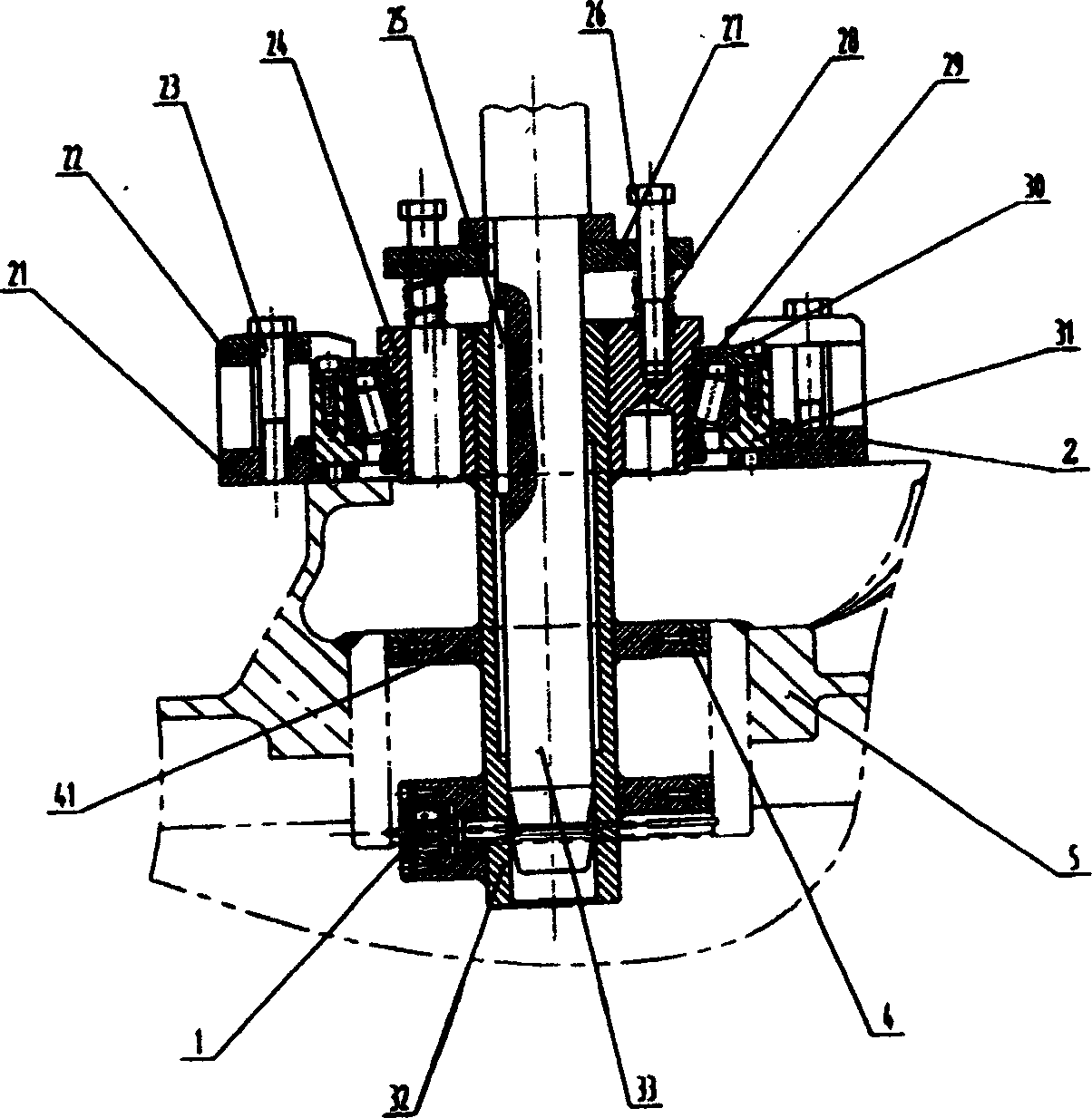

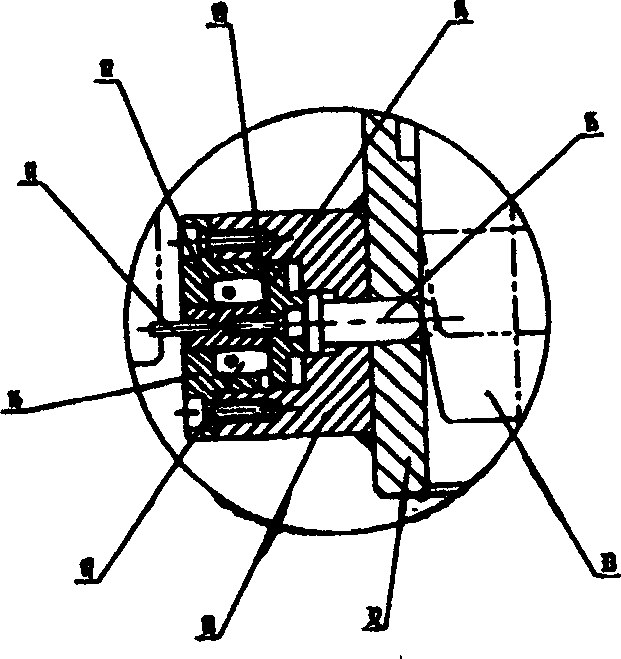

[0022] At present, the radial drilling machine is widely used in the field of mechanical processing, but the spindle movement of the existing radial drilling machine is rotary motion and vertical feed motion, and the inner groove of the bearing hole must be processed by boring with the radial drilling machine. The main problems are: 1), transmission and conversion of motion (drilling machine spindle lacks radial feed motion for boring inner groove); 2), width and depth control of inner groove; 3), inner groove boring Safe cutting and exiting of the blade; 4), the stability of the movement during processing; 5), the wear and replacement of the blade; 6), the cooling and lubrication of the blade, etc. Aiming at the above problems, the present invention designs a special fixture that can bore and process the inner groove of the bearing hole on a radial drilling machine, so that it can solve the above problems. Such as figure 1 As shown, it includes a bed 6, a rocker arm 7, a mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com